Abstract

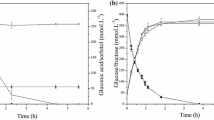

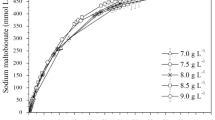

Lactobionic acid and sorbitol are produced from lactose and fructose in reactions catalyzed by glucose–fructose oxidoreductase and glucono-δ-lactonase, periplasmic enzymes present in Zymomonas mobilis cells. Considering the previously established laboratory-scale process parameters, the bioproduction of lactobionic acid was explored to enable the transfer of this technology to the productive sector. Aspects such as pH, temperature, reuse and storage conditions of Ca-alginate immobilized Z. mobilis cells, and large-scale bioconversion were assessed. Greatest catalyst performance was observed between pH range of 6.4 and 6.8 and from 39 to 43 °C. The immobilized biocatalyst was reused for twenty three 24-h batches preserving the enzymatic activity. The activity was maintained during biocatalyst storage for up to 120 days. Statistically similar results, approximately 510 mmol/L of lactobionic acid, were attained in bioconversion of 0.2 and 3.0 L, indicating the potential of this technique of lactobionic acid production to be scaled up to the industrial level.

Similar content being viewed by others

Change history

30 April 2020

In the original publication, table captions were incorrectly published. The correct captions are given here.

References

Tufvesson P, Fu W, Jensen JS, Woodley JM (2010) Food and bioproducts processing process considerations for the scale-up and implementation of biocatalysis. Food Bioprod Process 88:3–11. https://doi.org/10.1016/j.fbp.2010.01.003

Sumimoto R, Kamada N (1990) Lactobionate as the most important component in UW solution for liver preservation. Transplant Proc 22:2198–2199

Murzina EV, Tokarev AV, Kordás K et al (2008) d-Lactose oxidation over gold catalysts. Catal Today 131:385–392. https://doi.org/10.1016/j.cattod.2007.10.080

Park IK, Ihm JE, Park YH et al (2003) Galactosylated chitosan (GC)-graft-poly(vinyl pyrrolidone) (PVP) as hepatocyte-targeting DNA carrier: preparation and physicochemical characterization of GC-graft-PVP/DNA complex (1). J Control Release 86:349–359. https://doi.org/10.1016/S0168-3659(02)00365-6

Chernyy S, Jensen BEB, Shimizu K et al (2013) Surface grafted glycopolymer brushes to enhance selective adhesion of HepG2 cells. J Colloid Interface Sci 404:207–214. https://doi.org/10.1016/j.jcis.2013.04.025

Yu RJ, Van Scott EJ (2004) Alpha-hydroxyacids and carboxylic acids. J Cosmet Dermatol 3:76–87. https://doi.org/10.1111/j.1473-2130.2004.00059.x

Fischer E, Meyer J (1889) Oxydetion delr Milchsuckers. Berichte der Dtsch Chem Gesellschaft 22:361–364

Nath A, Verasztó B, Basak S et al (2016) Synthesis of lactose-derived nutraceuticals from dairy waste whey—a review. Food Bioprocess Technol 9:16–48. https://doi.org/10.1007/s11947-015-1572-2

Alonso S, Rendueles M, Díaz M (2013) Bio-production of lactobionic acid: current status, applications and future prospects. Biotechnol Adv 31:1275–1291. https://doi.org/10.1016/j.biotechadv.2013.04.010

Zachariou M, Scopes RK (1986) Glucose-fructose oxidoreductase, a new enzyme isolated from Zymomonas mobilis that is responsible for sorbitol production. J Bacteriol 167:863–869

Satory M, Fürlinger M, Haltrich D et al (1997) Continuous enzymatic production of lactobionic acid using glucose-fructose oxidoreductase in an ultrafiltration membrane reactor. Biotechnol Lett 19:1205–1208. https://doi.org/10.1023/A:1018485804167

Malvessi E, Carra S, Pasquali FC et al (2013) Production of organic acids by periplasmic enzymes present in free and immobilized cells of Zymomonas mobilis. J Ind Microbiol Biotechnol 40:1–10. https://doi.org/10.1007/s10295-012-1198-6

Delagustin MG, Gonçalves E, Carra S et al (2019) Sodium, potassium, calcium lactobionates, and lactobionic acid from Zymomonas mobilis: a novel approach about stability and stress tests. J Pharm Biomed Anal 174:104–114. https://doi.org/10.1016/j.jpba.2019.05.060

Delagustin MG, Gonçalves E, Carra S et al (2017) Bioproduction and characterization of sodium, potassium, and calcium lactobionates. Quim Nov. https://doi.org/10.21577/0100-4042.20170108

Malvessi E, Carra S, Silveira MM, Ayub MAZ (2010) Effect of substrate concentration, pH, and temperature on the activity of the complex glucose-fructose oxidoreductase/glucono-δ-lactonase present in calcium alginate-immobilized Zymomonas mobilis cells. Biochem Eng J 51:1–6

Folle AB, Baschera VM, Vivan LT et al (2018) Assessment of different systems for the production of aldonic acids and sorbitol by calcium alginate-immobilized Zymomonas mobilis cells. Bioprocess Biosyst Eng 41:185–194. https://doi.org/10.1007/s00449-017-1856-1

Niu X, Wang Z, Li Y et al (2013) “Fish-in-Net”, a novel method for cell immobilization of Zymomonas mobilis. PLoS ONE. https://doi.org/10.1371/journal.pone.0079569

Mohamad NR, Marzuki NHC, Buang NA et al (2015) Review; agriculture and environmental biotechnology an overview of technologies for immobilization of enzymes and surface analysis techniques for immobilized enzymes. Biotechnol Biotechnol Equip 29:205–220. https://doi.org/10.1080/13102818.2015.1008192

Carra S (2012) Estudo cinético da produção de ácido lactobiônico e sorbitol por enzimas periplasmáticas de Zymomonas mobilis. Dissertation Mestr, Universidade de Caxias do Sul, pp 1–107

Gacesa P (1988) Alginates. Carbohydr Polym 8:161–182. https://doi.org/10.1016/0144-8617(88)90001-X

Gombotz WR, Wee SF (2012) Protein release from alginate matrices. Adv Drug Deliv Rev 64:194–205. https://doi.org/10.1016/j.addr.2012.09.007

Malvessi E, Concatto K, Carra S, da Silveira MM (2006) Formulation of medium for growth and production of ethanol and intracellular enzymes by Zymomonas mobilis. Braz Arch Biol Technol 49:139–144

Rehr B, Wilhelm C, Sahm H (1991) Production of sorbitol and gluconic acid by permeabilized cells of Zymomonas mobilis. Appl Microbiol Biotechnol. https://doi.org/10.1007/BF00184677

Jang K-H, Jung S-J, Chang H-S, Chun U-H (1996) Improvement of the process for sorbitol production with Zymomonas mobilis immobilised in κ-carrageenan. Process Biochem 31:485–492. https://doi.org/10.1016/0032-9592(95)00092-5

Severo Júnior JB, Pinto JC, Ferraz HC, Alves TLM (2011) Analysis of experimental errors in bioprocesses. 1. Production of lactobionic acid and sorbitol using the GFOR (glucose–fructose oxidoreductase) enzyme from permeabilized cells of Zymomonas mobilis. J Ind Microbiol Biotechnol 38:1575–1585. https://doi.org/10.1007/s10295-011-0948-1

Pedruzzi I, Silva EAB, Rodrigues AE (2011) Production of lactobionic acid and sorbitol from lactose/fructose substrate using GFOR/GL enzymes from Zymomonas mobilis cells: a kinetic study. Enzyme Microb Technol 49:183–191. https://doi.org/10.1016/j.enzmictec.2011.04.017

Pedruzzi I, Malvessi E, Mata VG et al (2007) Quantification of lactobionic acid and sorbitol from enzymatic reaction of fructose and lactose by high-performance liquid chromatography. J Chromatogr A 1145:128–132. https://doi.org/10.1016/j.chroma.2007.01.051

Bailey JE, Ollis DF (1986) Biochemical engineering fundamentals. McGraw-Hill, New York

Chun UH, Rogers PL (1988) The simultaneous production of sorbitol from fructose and gluconic acid from glucose using an oxidoreductase of Zymomonas mobilis. Appl Microbiol Biotechnol 29:19–24. https://doi.org/10.1007/BF00258345

Acknowledgements

This study was supported by grants from the Coordenadoria de Aperfeiçoamento de Pessoal de Nível Superior (CAPES, Brazil), the Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq, Brazil), the Fundação de Amparo à Pesquisa do Estado do Rio Grande do Sul (FAPERGS, Brazil), Universidade Federal do Rio Grande do Sul (UFRGS), and the Universidade de Caxias do Sul (UCS).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Carra, S., Rodrigues, D.C., Beraldo, N.M.C. et al. High lactobionic acid production by immobilized Zymomonas mobilis cells: a great step for large-scale process. Bioprocess Biosyst Eng 43, 1265–1276 (2020). https://doi.org/10.1007/s00449-020-02323-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-020-02323-7