Abstract

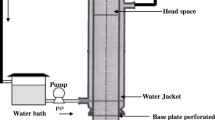

The production of protease enzyme was evaluated through the solid state fermentation (SSF) of soy fibre, a waste product that acted as a sole substrate for the fermentation, at a laboratory and bench scale using a 500-mL (batch size 115 g) and 10-L (batch size 2300 g) bioreactors. The objective was to assess the effect of the inoculation of the thermophilic bacteria Thermus sp. on the production of the enzyme when working at laboratory and bench scale under non-sterile conditions, since scaling-up and the need of sterilization are the main challenges of SSF, preventing its industrial development. Results revealed that the inoculation led to a substantial increase in the protease obtained on both scales when compared to non-inoculated fermentation. The maximum protease activities increased as a result of the inoculation from 500 to 800 and from 350 to 670 U/g dry matter of soy fibre in the lab and bench scale bioreactors, respectively. Finally, a very good correlation was found between the protease activities obtained and the fermentation most relevant parameters: oxygen uptake rate (R 2 = 0.81) and temperature (R 2 = 0.82). In this work, we have demonstrated that inoculation is effective even under non-sterile conditions at the kg scale and that this strain is able to compete with autochthonous microbiota and increase the protease production to levels higher than those previously reported in literature.

Similar content being viewed by others

References

Pandey A, Soccol C, Larroche C (2008) Current developments in solid-state fermentation. Springer, Asiatech Publishers Inc, New Delhi

Singhania RR, Patel AK, Soccol C, Pandey A (2009) Recent advances in solid-state fermentation. Biochem Eng J 44:13–18

Salihu A, Alam Z, Abdulkarim I, Salleh H (2012) Lipase production: an insight in the utilization of renewable agricultural residues. Res Cons Recyc 58:36–44

Abraham J, Gea T, Sánchez A (2013) Potential of the solid-state fermentation of soy fibre residues by native microbial populations for bench-scale alkaline protease production. Biochem Eng J 74:15–19

Abraham J, Gea T, Sánchez A (2014) Substitution of chemical dehairing by proteases from solid- state fermentation of hair wastes. J Cleaner Prod 74:191–198

Sukumaran RK, Patel AK, Larroche C, Pandey A (2010) Advancement and comparative profiles in the production technologies using solid-state and submerged fermentation for microbial cellulases. Enzyme Microb Tech 46:541–549

Turk B (2006) Targeting proteases: successes, failures and future prospects. Nature Rev Drug Disc 5:785–798

El-Bakry M, Abraham J, Cerda A, Barrena R, Ponsá S, Gea T, Sánchez A (2015) From wastes to high value added products: novel aspects of SSF in the production of enzymes. Crit Rev Env Sci Technol available on-line: doi:10.1080/10643389.2015.1010423

Vijayaraghavana P, Vincent G (2012) Cow dung as a novel, inexpensive substrate for the production of a halo-tolerant alkaline protease by Halomonas sp. PV1 for eco-friendly Applications. Biochem Eng J 69:57–60

Mukherjee AK, Adhikari K, Rai SK (2008) Production of alkaline protease by a thermophilic Bacillus subtilis under solid-state fermentation (SSF) condition using Imperata cylindrica grass and potato peel as low-cost medium: characterization and application of enzyme in detergent formulation. Biochem Eng J 39:353–361

Rai SK, Konwarh R, Mukherjee AK (2009) Purification, characterization and biotechnological application of an alkaline-keratinase produced by Bacillus subtilis RM-01 in solid-state fermentation using chicken-feather as substrate. Biochem Eng J 45:218–225

Thanapimmetha A, Luadsongkrama A, Titapiwatanakunc B, Srinophakun P (2012) Value added waste of Jatropha curcas residue: optimization of protease production in solid state fermentation by Taguchi DOE methodology. Ind Crops Prod 37:1–5

Gaur R, Tiwari S, Sharma (2014) Isolation and Characterization of Thermotolerant Alkaline Serine Protease of Bacillus sp. P-02. Am J Food Tech 9:246–956

Ruggieri F, Gea T, Artola A, Sánchez A (2009) Air filled porosity measurements by air pycnometry in the composting process: a review and a correlation analysis. Biores Technol 100:2655–2666

The US Department of Agriculture and The US Composting Council. Test Methods for the Examination of Composting and Compost (2001) Houston: Edaphos International

Ponsá S, Gea T, Sánchez A (2010) Different indices to express biodegradability in organic solid wastes. J Env Qual 39:706–712

Alef K, Nannipieri P (1995) Methods in applied soil microbiology and biochemistry. Academic Press Limited, San Diego

Minitab, Minitab 15.1 reference manual (2007) Minitab Inc

García MC, Torreu M, Marina ML, Laborda F (1997) Composition and characterization of soybean and related products. Crit Rev Food Sci Nut 37:361–391

Cheirsilp B, Kitcha S (2015) Solid state fermentation by cellulolytic oleaginous fungi for direct conversion of lignocellulosic biomass into lipids: fed-batch and repeated-batch fermentations. Ind Crops Prod 66:73–80

Acknowledgments

This study was financially supported by the Spanish Ministerio de Economía y Competitividad (Project CTM2012-33663). Mamdouh El-Bakry was recipient of a postdoctoral fellowship from Universitat Autònoma de Barcelona.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

El-Bakry, M., Gea, T. & Sánchez, A. Inoculation effect of thermophilic microorganisms on protease production through solid-state fermentation under non-sterile conditions at lab and bench scale (SSF). Bioprocess Biosyst Eng 39, 585–592 (2016). https://doi.org/10.1007/s00449-016-1540-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-016-1540-x