Abstract

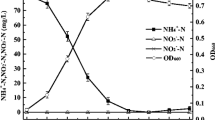

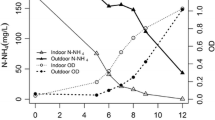

The growth rate and desulfurization capacity accumulated by the cells during the growth of Pseudomonas putida KTH2 under different oxygen transfer conditions in a stirred and sparged tank bioreactor have been studied. Hydrodynamic conditions were changed using different agitation conditions. During the culture, several magnitudes associated to growth, such as the specific growth rate, the dissolved oxygen concentration and the carbon source consumption have been measured. Experimental results indicate that cultures are influenced by the fluid dynamic conditions into the bioreactor. An increase in the stirrer speed from 400 to 700 rpm has a positive influence on the cell growth rate. Nevertheless, the increase of agitation from 700 to 2000 rpm hardly has any influence on the growth rate. The effect of fluid dynamics on the cells development of the biodesulfurization (BDS) capacity of the cells during growth is different. The activities of the intracellular enzymes involved in the 4S pathway change with dissolved oxygen concentration. The enzyme activities have been evaluated in cells at several growth time and different hydrodynamic conditions. An increase of the agitation from 100 to 300 rpm has a positive influence on the development of the overall BDS capacity of the cells during growth. This capacity shows a decrease for higher stirrer speeds and the activity of the enzymes monooxygenases DszC and DszA decreases dramatically. The highest value of the activity of DszB enzyme was obtained with cells cultured at 100 rpm, while this activity decreases when the stirrer speed was increased higher than this value.

Similar content being viewed by others

Abbreviations

- a j :

-

Activity of enzyme j \( \left( \rm{\mu M \ g_{{C_{X} }}^{ - 1} \ min^{ - 1} } \right) \)

- BDS:

-

Biodesulfurisation

- C* :

-

Oxygen concentration in equilibrium (mol L−1)

- Cj :

-

Concentration of compound j \( \left( \rm{\mu M \ L^{ - 1} } \right) \)

- CO2 :

-

Oxygen dissolved concentration (% or mol·m−3)

- C X :

-

Concentration of biomass \( \left( {g_{X} \cdot L^{ - 1} } \right) \)

- D:

-

Stirrer diameter (m)

- DBT:

-

Dibenzothiophene

- DBTO:

-

Dibenzothiophene sulfoxide

- DBTO2 :

-

Dibenzothiophene-sulfone

- F:

-

Fischer statistical parameter

- HBP:

-

2-Hydroxybiphenyl

- HBPS:

-

2-Hydroxybiphenyl-2-sulfinic acid

- k L a :

-

Volumetric oxygen mass transfer coefficient (s−1)

- N:

-

Stirrer speed (rpm)

- OTR:

-

Oxygen transfer rate (mol O2L−1s−1)

- OUR:

-

Oxygen uptake rate (mol O2L−1s−1)

- Re :

-

Impeller Reynolds number (–)

- SSR:

-

Sum of square residuals

- T :

-

Vessel diameter (m)

- t :

-

Time (min, s or h)

- V :

-

Volume (m3)

- Xj :

-

Conversion or yield of compound j (–)

- η :

-

Effectiveness factor for growth (–)

- µ :

-

Specific growth rate (h−1)

- G :

-

Relative to gas phase

- L :

-

Relative to liquid phase

- Max:

-

Referred to maximum value

- O2 :

-

Referred to oxygen

- X :

-

Referred to biomass

- 0:

-

Referred to initial value

- t :

-

Referred to time of 120 min of resting cell assay

- 0:

-

Referred to initial value

References

Garcia-Ochoa F, Gomez E (2009) Bioreactor scale-up and oxygen transfer rate in microbial processes: an overview. Biotechnol Adv 27:153–176

Märkl H, Bronnenmeier R, Wittek B (1991) The resistance of microorganisms to hydrodynamic stress. Int Chem Eng. 31:185–197

Sahoo S, Verma RK, Suresh AK, Rao KK, Bellare J, Suraishkumar GK (2003) Macro-level and genetic-level responses of bacillus subtilis to shear stress. Biotechnol Prog 19:1689–1696

Chisty Y (2010). In: M.C. Flickinger (ed) Shear Sensitivity in Encyclopedia of Industrial Biotechnology: Bioprocess, Bioseparation, and Cell Technology. John Wiley & Sons, New York

Hodaifa G, Martinez ME, Orpez R, Sanchez S (2010) Influence of hydrodynamic stress in the growth of Scenedesmus obliquus using a culture medium based on olive mill waste water. Chem Eng Process 49:1161–1168

Calik P, Yilgör P, Ayhan P, Demir A (2004) Oxygen transfer effects on recombinant benzaldehyde lyase production. Chem Eng Sci 59:5075–5083

Olmos E, Mehmood N, Haj-Husein L, Goergen JL, Fick M, Delaunay S (2013) Effects of bioreactor hydrodynamics on the physiology of Streptomyces. Bioprocess Biosyst Eng 36:259–272

Prokop A, Bajpai RK (1992) The sensitivity of biocatalysts to hydrodynamic shear stress. Adv Appl Microbiol 37:165–232

Hewitt CJ, Boon LA, McFarlane CM, Nienow AW (1998) The use of flow cytometry to study the impact of fluid mechanical stress on Escherichia coli W3110 during continuous cultivation in an agitated bioreactor. Biotechnol Bioeng 59:612–620

Meijer JJ, ten Hoopen HJG, van Gameren YM, Luyben KChAM, Libbenga KR (1994) Effects of hydrodynamic stress on the growth of plant cells in batch and continuous culture. Enz Microb Technol 16:467–477

Yepez BO, Maugeri F (2005) Agitation, aeration and shear stress as key factors in inulinase production by Kluyveromyces marxianus. Enz Microb Technol 36:717–724

Garcia-Ochoa F, Gomez E, Alcon A, Santos VE (2013) The effect of hydrodynamic stress on the growth of Xanthomonas campestris cultures in a stirred and sparged tank bioreactor. Bioprocess Biosyst Eng 36:911–925

Kao P-M, Chen C-I, Huang S-C, Chang Y-C, Tsay P-Y, Liu Y-C (2007) Effects of shear stress and mass transfer on chitinase production by Paenibacillus sp. CHE-N1. Biochem Eng J 34:172–178

Arnaud JP, Lacroix C, Foussereau C, Choplin L (1993) Shear stress effects on growth and activity of Lactobacillus delbrueckii subsp. Bulgaricus. J Biotechnol 29:157–175

Bronnenmeier R, Markl H (1982) Hydrodynamic stress capacity of microorganisms. Biotech Bioeng 24:553–578

Denome SA, Olson ES, Young KD (1993) Identification and cloning of genes involved in specific desulfurization of dibenzothiophene by Rhodococcus sp. strain IGTS8. Appl Environ Microbiol 59:2837–2843

McFarland BL (1999) Biodesulfurization. Curr Opin Microbiol 2:257–264

Maghsoudi S, Vossoughi M, Kheirolomoom A, Tanaka E, Katoh S (2001) Biodesulfurization of hydrocarbons and diesel fuels by Rhodococcus sp. strain P32C1. Biochem Eng J 8:151–156

Martin AB, Alcon A, Santos VE, Garcia-Ochoa F (2004) Production of a biocatalyst of Pseudomonas putida CECT5279 for dibenzothiophene (DBT) biodesulfurization for different media compositions. Energy Fuels 18:851–857

Martin AB, Alcon A, Santos VE, Garcia-Ochoa F (2005) Production of a biocatalyst of Pseudomonas putida CECT5279 for DBT biodesulfurization: influence of the operational conditions. Energy Fuels 19:775–782

Alcon A, Santos VE, Martin AB, Yustos P, Garcia-Ochoa F (2005) Biodesulfurization of DBT with Pseudomonas putida CECT5279 by resting cells: influence of cell growth time on reducing equivalent concentration and HpaC activity. Biochem Eng J 26:168–175

Alcon A, Martin AB, Santos VE, Gomez E, Garcia-Ochoa F (2008) Kinetic model for DBT desulphurization by resting whole cells of Pseudomonas putida CECT5279. Biochem Eng J 39:486–495

Gomez E, Santos V, Alcon A, Martin AB, Garcia-Ochoa F (2006) Oxygen-uptake and mass-transfer rates on the growth of Pseudomonas putida CECT5279: influence on biodesulfurization (BDS) capability. Energy Fuels 20:1565–1571

Gomez E, Alcon A, Escobar S, Santos VE, Garcia-Ochoa F (2015) Effect of fluid dynamic conditions on growth rate and biodesulfurization capacity of Rhodococcus erythropolis IGTS8. Biochem Eng J 99:138–146

Oldfield C, Pogrebinsky O, Simmonds J, Olson ES, Kulpa CH (1997) Elucidation of the metabolic pathway for dibenzothiophene desulfurization by Rhodococcus sp. strain IGTS8 (ATCC 53968). Microbiology 143:2961–2973

Galan B, Diaz E, Garcia JL (2000) Enhancing desulphurization by engineering a flavin reductase-encoding gene cassette in recombinant biocatalysts. Environ Microbiol 2:687–694

Galan B, Diaz E, Fernandez A, Prieto MA, Garcia JL, Garcia-Ochoa F, Garcia Calvo E (2001) Method for desulfurization of dibenzothiophene using a recombinant Pseudomonas putida strains as biocatalyst. International Patent WO 01/70996 AL

Calzada J, Zamarro MT, Alcon A, Santos VE, Diaz E, Garcia JL, Garcia-Ochoa F (2009) Analysis of dibenzothiophene desulfurization in a recombinant Pseudomonas putida strain. Appl Environ Microbiol 75:875–877

Luedeking R, Piret EL (1959) A kinetic study of the lactic acid fermentation: batch process at controlled pH. J Biochem Microbiol Technol Eng 1:393–412

Weiss RM, Ollis DF (1980) Extracellular microbial polysaccharides. I. Substrate, biomass, and product kinetic equations for batch xanthan gum fermentation. Biotech Bioeng 22:859–873

Garcia-Ochoa F, Gomez E (2004) Theoretical prediction of gas-liquid mass transfer coefficient, specific area and hold-up in sparged stirred tanks. Chem Eng Sci 59:2489–24501

Garcia-Ochoa F, Gomez E (2005) Prediction of gas-liquid mass transfer in sparged stirred tank bioreactors. Biotech Bioeng 92:761–772

Santos VE, Galdeano C, Gomez E, Alcon A, Garcia-Ochoa F (2006) Oxygen uptake rate measurements both by the dynamic method and during the process growth of Rhodococcus erythropolis IGTS8: modelling and difference in results. Biochem Eng J 32:198–204

Garcia-Ochoa F, Gomez E (2010) Oxygen transfer rate: determination, chemical, physical and biological methods. In: Flickinger MC (ed) Encyclopedia of industrial biotechnology: bioprocess, bioseparation, and cell technology. Wiley, Hoboken

Martinez I, Santos VE, Gomez E, Garcia-Ochoa F (2014) Biodesulfurization of dibenzothiophene by resting cells of Pseudomonas putida CECT5279: influence of the oxygen transfer rate in the scale-up from shaken flask to stirred tank reactor. J Chem Technol Biotechnol. doi:10.1002/jctb.4559

Etemadifar Z, Emtiazi G, Christofi N (2008) Enhanced Desulfurization Activity in Protoplast Transformed Rhodococcus erythropolis. Am Eurasian J Agric Environ Sci 3:795–801

Marquardt AW (1963) An algorithm for least-squares estimation of nonlinear parameters. J Soc Ind Appl Math 11:431–441

Acknowledgments

This work has been supported by MICINN under contracts CTQ2013-45970-C2-1-R, CTQ2011-12725-E and BSCH-UCM, GR35/10-A 910134.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Escobar, S., Rodriguez, A., Gomez, E. et al. Influence of oxygen transfer on Pseudomonas putida effects on growth rate and biodesulfurization capacity. Bioprocess Biosyst Eng 39, 545–554 (2016). https://doi.org/10.1007/s00449-016-1536-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-016-1536-6