Abstract

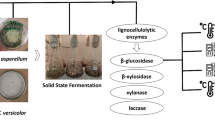

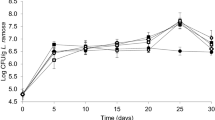

The recovery of by-products from agri-food industry is currently one of the major challenges of biotechnology. Castilla-La Mancha produces around three million tons of waste coming from olive oil and wine industries, both of which have a pivotal role in the economy of this region. For this reason, this study reports on the exploitation of grape skins and olive pomaces for the production of lignocellulosic enzymes, which are able to deconstruct the agroindustrial waste and, therefore, reuse them in future industrial processes. To this end, solid-state fermentation was carried out using two local fungal strains (Aspergillus niger—113 N and Aspergillus fumigatus—3). In some trials, a wheat supplementation with a 1:1 ratio was used to improve the growth conditions, and the particle size of the substrates was altered through milling. Separate fermentations were run and collected after 2, 4, 6, 8, 10 and 15 days to monitor enzymatic activity (xylanase, cellulase, β-glucosidase, pectinase). The highest values were recorded after 10 and 15 days of fermentation. The use of A. niger on unmilled grape skin yielded the best outcomes (47.05 U xylanase/g by-product). The multi-enzymatic extracts obtained were purified, freeze dried, and immobilized on chitosan by adsorption to assess the possible advantages provided by the different techniques.

Similar content being viewed by others

References

Cara C, Ruiz E, Oliva JM, Sáez F, Castro E (2008) Conversion of olive tree biomass into fermentable sugars by dilute acid pretreatment and enzymatic saccharification. Bioresour Technol 99:1869–1876

Singhania RR, Patel AK, Soccol CR, Pandey A (2009) Recent advances in solid-state fermentation. Biochem Eng J 44:13–18

Holker U, Hofer M, Lenz J (2004) Biotechnological advantages of laboratory-scale solid-state fermentation with fungi. Appl Microbiol Biotechnol 64:175–186

Couto SR, Sanromán MA (2006) Application of solid-state fermentation to food industry—a review. J Food Eng 76:291–302

da Silva R, Lago ES, Merheb CW, Macchione MM, Park YK, Gomes E (2005) Production of xylanase and CMCase on solid state fermentation in different residues by Thermoascus aurantiacus Miehe. Braz J Microbiol 36:235–241

Soliman HM, Sherief A-DA, El-Tanash AB (2012) Production of xylanase by Aspergillus niger and Trichoderma viride using some agriculture residues. Int J Agric Res 7:46–57

Kashyap DR, Vohra PK, Chopra S, Tewari R (2001) Applications of pectinases in the commercial sector: a review. Bioresour Technol 77:215–227

Jin B, Yan XQ, Yu Q, van Leeuwen JH (2002) A comprehensive pilot plant system for fungal biomass protein production and wastewater reclamation. Adv Environ Res 6:179–189

Salihu A, MdZ Alam, AbdulKarima MI, Salleh HM (2012) Lipase production: an insight in the utilization of renewable agricultural residues. Resour Conserv Recycl 58:36–44

Alves-Baffi M, Romo-Sánchez S, Úbeda-Iranz J, Briones-Pérez A (2012) Fungi isolated from olive ecosystems and screening of their potential biotechnological use. New Biotechnol 29:451–456

Castellani A (1939) Viability of some pathogenic fungi in distilled water. J Trop Med Hyg 42:225–226

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugars. Anal Chem 31:426–428

Arévalo-Villena M, Díez Pérez J, Úbeda JF, Navascués E, Briones AI (2006) A rapid method for quantifying aroma precursors: application to grape extract, musts and wines made from several varieties. Food Chem 99:183–190

Arévalo-Villena M, Úbeda-Iranzo JF, Briones-Pérez A (2007) β–glucosidase activity in wine yeasts: application in enology. Enzyme Microb Tech 40:420–425

Palacios A, Santiago L, Guerrand D Utilización de enzimas de maceración en vinificación en tinto. Personal communication

Ncube T, Howard RL, Abotsi EK, Jansen van Rensburg EL, Ncube I (2012) Jatropha curcas seed cake as substrate for production of xylanase and cellulose by Aspergillus niger FGSCA733 in solid state-fermentation. Ind Crop Prod 37:118–123

Krisana A, Rutchadaporn S, Jarupan G, Lily E, Sutina T, Kanyawim K (2005) Endo-1,4-β-xylanase B from Aspergillus cf. niger BCC14405 isolated in Thailand: purification, characterization and gene isolation. J Biochem Mol Biol 38:17–23

Arévalo-Villena M, Úbeda-Iranzo J, Briones-Pérez AI (2006) Relationship between Debaryomyces pseudopolymorphus enzymatic extracts and release of terpenes in wine. Biotechnol Prog 22:375–381

García-López MD, Uruburu-Fernández F La conservación de cepas microbianas. Colección española de cultivos tipo. Personal communication

Romo S, Camacho C, Gómez L, Villalonga-Santana R, Úbeda-Iranzo J, Arévalo-Villena M, Briones-Pérez A, Ramírez HL (2012) Inmovilización de celulasa sobre una matriz de quitina-quitosana. Revista Cubana de Química 24:57–64

Georgieva TI, Ahring BK (2007) Potential of agroindustrial waste from olive oil industry for fuel ethanol production. Biotechnol J 2:1547–1555

González-Centeno MR, Roselló C, Simal S, Garau MC, López F, Femenia A (2010) Physico-chemical properties of cell wall materials obtained from ten grape varieties and their byproducts: grape pomaces and stems. LWT Food Sci Technol 43:1580–1586

Mitchell DA, Lonsane BK (1992) Definition, characteristics and potential in solid substrate cultivation. In: Doelle HW, Mitchell DA, Rol CE (eds) Solid state fermentation. Elsevier, New York, pp 455–467

van de Velde F, Lourenco ND, Bakker M, van Rantwijk F, Sheldon RA (2000) Improved operational stability of peroxidases by coimmobilization with glucose oxidase. Biotechnol Bioeng 69:286–291

Acknowledgments

The authors wish to express their gratitude to Dr. Mario Canales for protein electrophoresis assistant and to Dr. Hector L. Ramirez for immobilization process.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Romo Sánchez, S., Gil Sánchez, I., Arévalo-Villena, M. et al. Production and immobilization of enzymes by solid-state fermentation of agroindustrial waste. Bioprocess Biosyst Eng 38, 587–593 (2015). https://doi.org/10.1007/s00449-014-1298-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-014-1298-y