Abstract

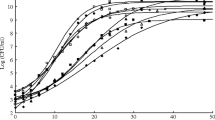

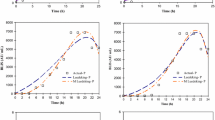

The effect of pH and temperature on cell growth and bacteriocin production in Lactococcus lactis C7 was investigated in order to optimize the production of bacteriocin. The study showed that the bacteriocin production was growth-associated, but declined after reaching the maximum titer. The decrease of bacteriocin was caused by a cell-bound protease. Maximum bacteriocin titer was obtained at pH 5.5 and at 22°C. In order to obtain a global optimized solution for production of bacteriocin, the optimal temperature for bacteriocin production was further studied. Mathematical models were developed for cell growth, substrate consumption, lactic acid production and bacteriocin production. A Differential Evolution algorithm was used both to estimate the model parameters from the experimental data and to compute a temperature profile for maximizing the final bacteriocin titer and bacteriocin productivity. This simulation showed that maximum bacteriocin production was obtained at the optimal temperature profile, starting at 30°C and terminating at 22°C, which was validated by experiment. This temperature profile yielded 20% higher maximum bacteriocin productivity than that obtained at a constant temperature of 22°C, although the total amount of bacteriocin obtained was slightly decreased.

Similar content being viewed by others

Abbreviations

- J :

-

Objective function of optimal control problem

- ϕ:

-

Linear or nonlinear function

- f :

-

Dynamic function vector

- u :

-

Control variable

- x :

-

State vector

- t :

-

Time in hours (h)

- \(\tilde {\mathbf{u}}\) :

-

Expression defined by Eq. 6

- m :

-

Number of time intervals

- t f :

-

Final time

- LB:

-

Lower bound on control variable

- UB:

-

Upper bound on control variable

- F :

-

Differential variation constant

- CR:

-

Crossover constant

- N P :

-

Population size

- N G :

-

Maximum number of generations

- ɛ:

-

Tolerance for convergence

- ɛ1 :

-

Desired tolerance

- ɛ2 :

-

Assigned tolerance for gene diversity

- ρ:

-

Degree of population diversity

- X :

-

Cell concentration (OD660)

- μ:

-

Specific growth rate (h−1)

- μmax :

-

Maximum specific growth rate (h−1)

- S :

-

Residual glucose (g l−1)

- L :

-

Lactic acid concentration (g l−1)

- K S :

-

The saturation constant of Monod equation (g l−1)

- K P :

-

Lactic acid inhibition constant (g l−1)

- α:

-

Growth-associated constant for lactic acid production (g l−1)

- β:

-

Non-growth associated constant for lactic acid production (g l−1 h−1)

- γ:

-

Expression defined by Eq. 16

- ξ:

-

Expression defined by Eq. 16

- Y X :

-

Cell-yield coefficient (l/g)

- Y P :

-

Yield coefficient of lactic acid

- δ:

-

Cell maintenance coefficient (g l−1 h−1)

- K :

-

Expression defined by Eq. 17

- B :

-

Bacteriocin titer (AU ml−1)

- K B :

-

Specific bacteriocin production rate (AU ml−1)

- K D :

-

Specific bacteriocin degradation rate (h−1)

- L :

-

Expression defined by Eq. 21

- V:

-

Vector of parameters

- T :

-

Temperature (°C)

References

Holzapfel WH, Geisen R, Schillinger U (1995) Biological preservation of foods with reference to protective cultures, bacteriocins and food-grade enzymes. Int J Food Microbiol 24:343–362

Jack RW, Tagg JR, Ray B (1995) Bacteriocins of gram positive bacteria. Microbiol Rev 59:171–200

Schillinger U, Lucke FK (1989) Antibacterial activity of Lactobacillus sake isolated from meat. Appl Environ Microbiol 55:1901–1906

Malik RK, Kumar N, Rao KN, Mathur DK (1994) Bacteriocins-antibacterial proteins of lactic acid bacteria: a review. Microbiol Aliments Nutr 12:117–132

De Vuyst L, Vandamme EJ (1992) Influence of the carbon source on nisin production in Lactococcus lactis subsp. lactis batch fermentations. J Gen Microbiol 138:571–578

Parente E, Ricciardi A, Addario G (1994) Influence of pH on growth and bacteriocin production by Lactococcus lactis subsp. lactis 140NWC during batch fermentation. Appl Microbiol Biotechnol 41:388–394

Møortvedt-Abildgaard CI, Nissen-Meyer J, Jelle B, Grenov B, Skaugen M, Nes IF (1995) Production and pH-dependent bactericidal activity of lactocin S, a lantibiotic from Lactobacillus sake L45. Appl Environ Microbiol 61:175–179

Leroy F, De Vuyst L (1999) Temperature and pH conditions that prevail during fermentation of sausages are optimal for production of the antilisterial bacteriocin sakacin K. Appl Environ Microbiol 65:974–981

Leal-Sanchez MV, Jimenez-Diaz R, Maldonado-Barragan A, Garrido-Fernandez A, Ruiz-Barba JL (2002) Optimization of Bacteriocin Production by Batch Fermentation of Lactobacillus plantarum LPCO10. Appl Environ Microbiol 68:4465–4471

Krier F, Revol-Junelles AM, Germain P (1998) Influence of temperature and pH on production of two bacteriocins by Leuconostoc mesenteroides subsp. mesenteroides FR52 during batch fermentation. Appl Microbiol Biotechnol 50:359–363

Imphol U, Suriyawong P, Pongpan A, Wiwat C (2003) Characterization of bacteriocin from Lactococcus lactis subsp. lactis C7 isolated from fermented food. Thai J Biotechnol 4(1):9–15

Niamsup P, Sujaya N, Tanaka M, Sone T, Hanada S, Kamagata Y, Lumyong S, Assavanig A, Asano K, Tomita F, Yokota A (2003) Lactobacillus thermotolerans sp. nov., a novel thermotolerant species isolated from chicken faeces. Int J Syst Evol Microbiol 53:263–268

Tramer J, Fowler G (1964) Estimation of nisin in foods. J Sci Food Agri 15:522–528

Lee MH, Han C, Chang KS (1999) Dynamic optimization of a continuous polymer reactor using a modified differential evolution. Ind Eng Chem 38:4825–4831

Storn R, Price K (1996) Minimizing the Real Functions of the ICEC’96 Contest by Differential Evolution. In: Proceedings of the 1996 IEEE Conference on Evolutionary Computation, IEEE Press, NJ, pp 842–844

Price K (1997) Differential evolution vs. the functions of the 2nd ICEO. In: Proceedings of 1997 IEEE International Conference on Evolutionary Computation (ICEC ’97), Indianapolis, IN, USA, 13–16 April 1997, pp 153–157

Lopez Cruz IL, Van Willigenburg LG, Van Straten G (2003) Efficient Differential Evolution algorithms for multimodal optimal control problems. Appl Soft Comput 3(2):97–122

Mayer DG (2002) Evolutionary algorithms and agricultural systems. Kluwer, Boston

Lopez Cruz IL, Van Willigenburg LG, Van Straten G (2001) Parameter control strategy in differential evolution algorithm for optimal control. In: Hamza MH (ed) Proceedings of the IASTED international conference artificial intelligence and soft computing (ASC 2001), May 21–24, 2001, Cancun, Mexico, pp 211–216. ACTA Press, Calgary (Canada)

Aborhey S, Williamson D (1977) Modeling of lactic acid production by Streptococcus cremoris hp. J Gen Appl Microbiol 23:7–21

Luedeking R, Piret EL (1959) Transient and steady states in continuous fermentation Theory and experiment. J Biochem Microbiol Tech Eng 1:431–459

Parente E, Brienza C, Ricciardi A, Addario G (1997) Growth and bacteriocin production by Enterococcus faecium DPC1146 in batch and continuous culture. J Ind Microbiol Biotechnol 18:62–67

Lejeune R, Callewaert R, Crabbe K, De Vuyst L (1998) Modelling the growth and bacteriocin production by Lactobacillus amylovorus DCE 471 in batch cultivation. J Appl Bacteriol 84:159–168

Tangkitchawankul P (2003) Process development and optimization for bacteriocin production by Lactococcus lactis. MS Thesis in Biotechnology, Mahidol University, Bangkok

Chiou JP, Wang FS (2001) Estimation of Monod model parameters by hybrid differential evolution. Bioproc Biosyst Eng 24:109–113

Deb K (2001) Multi-objective optimization using evolutionary algorithms. Wiley, New York

Fu W, Mathews AP (1999) Lactic acid production from lactose by Lactobacillus plantarum: kinetic model and effects of pH, substrate, and oxygen. Biochem Eng J 3:163–170

Berry AR, Franco CMM, Zhang W, Middelberg APJ (1999) Growth and lactic acid production in batch culture of Lactobacillus rhamnosus in a defined medium. Biotechnol Lett 21:163–167

De Vuyst L, Callewaert R, Crabbé K (1996) Primary metabolite kinetics of bacteriocin biosynthesis by Lactobacillus amylovorus and evidence for stimulation of bacteriocin production under unfavourable growth conditions. Microbiol 142:817–827

Harvey RJ (1965). Damage to Streptococcus lactis resulting from growth at low pH. J Bacteriol 90:1330–1336

Batt CA (2000) Lactococcus. In: Robinson RK, Batt CA, Patel PD (eds) Encyclopedia of food microbiology. Academic, London, pp 1164–1171

Cachon R, Diviès C (1993) Modeling of growth and lactate fermentation by Lactococcus lactis subsp. lactis biovar diacetylactis in batch culture. Appl Microbiol Biotechnol 40:28–33

Ohara H, Hiyama K, Yoshida T (1992) Non-competitive product inhibition in lactic acid fermentation from glucose. Appl Microbiol Biotechnol 36:773–776

Rogers PL, Bramall L, McDonald IJ (1978) Kinetic analysis of batch and continuous culture of S treptococcus cremoris HP. Can J Microbiol 24:372–380

Wang FS, Chiou JP (1997) Differential evolution for dynamic optimization of differential- algebraic systems. In: Proceedings of the ieee international conference on evolutionary computation ICEC’97, Indianapolis, IN, pp 531–536, EE Press. IEEE Cat. No: 97TH8283

Chiou JP, Wang FS (1998) A hybrid method of differential evolution with application to optimal control problems of a bioprocess system. In: The 1998 IEEE international conference on evolutionary computation proceedings, 1998. IEEE World Congress on Computational Intelligence, pp 627–632

Lee MH, Han C, Chang KS (1999) Dynamic optimization of a continuous polymer reactor using a modified differential evolution. Ind Eng Chem 38:4825–4831

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Moonchai, S., Madlhoo, W., Jariyachavalit, K. et al. Application of a mathematical model and Differential Evolution algorithm approach to optimization of bacteriocin production by Lactococcus lactis C7. Bioprocess Biosyst Eng 28, 15–26 (2005). https://doi.org/10.1007/s00449-005-0004-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-005-0004-5