Abstract

The rolling process induces a heterogeneous deformation over the rolling stock height. The causes are the frictional shear stress between the contacting surfaces and the roll gap geometry. They induce a complex material flow within the rolling stock describable by the shear evolution. The shear evolution has a significant impact on rolling values like grain size and crystallographic texture and therefore on the final material properties of the rolled product. Industry and academia use fast rolling models for flat rolling processes to predict the material properties due to their short computation time. The time advantage enables online applicability to adapt processes in real time or to evaluate the influence of different process conditions several times within seconds. However, these models have a limitation regarding the shear evolution. They do not consider all relevant influences or apply simplifying assumptions, valid only for specific rolling cases. This work presents a general approach to extend fast rolling models to consider the shear evolution without any restrictions to specific rolling cases. The approach derives the shear evolution as shear angle \(\alpha\) evolution based on FE simulations. The shear angle \(\alpha\) is a geometrical description and not influenced by rotations, which occur during the rolling process. This enables an enhanced and simple analysis of the material flow. The outcome is an extended model that completely describes the deformation along a deformation path and enables the calculation of each desired deformation value (strain, deformation gradient, velocity gradient, etc.).

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Simulation models are indispensable for flat rolling process design and optimization. These models can be roughly divided into two categories in terms of computational time and complexity [1, 2]. The first category consists of slow and complex models that offer high accuracy. A popular representative of this model type is the finite element method (FEM) [3,4,5,6,7,8] combined with complex material models [9,10,11,12], contact formulations [13, 14] and multiscale approaches [15,16,17,18,19]. Models from the second category are characterized by lower complexity and shorter computation times, typically used to determine integral rolling target values like the roll force [20] or the total equivalent strain [21]. The short computation time is based on simplifications, which come with a lower accuracy for a single simulation run with these models. On the other hand, more complex process optimization is possible with this category of models as they can simulate the process under varying process conditions several times within seconds [22, 23]. Several popular representatives have been developed throughout the last century [24], e.g. the fast rolling models by Orowan [25], Bland and Ford [26], Sims [20], Alexander [27], Roychoudhuri and Lenard [28], Zeman et al. [29]. Furthermore, an online-based process design is possible with these fast models to adapt processes in real time [30,31,32]. Due to these advantages, the fast rolling models are popular in the industry [33, 34] and are employed in academia for machine learning and Industry 4.0 applications as virtual rolling mill [35]. The extension and adaption of the fast rolling models towards more realistic and more complex phenomena without losing the advantage of low computational effort is an ongoing challenge.

Fast rolling models steadily improved over the years and features have been added. Initial assumptions of rigid rollers [36] have been replaced by elastic rollers [37] and advanced material models were implemented to calculate microstructure evolution like recrystallization, grain size and texture [38,39,40,41]. At this point, the description of the shear evolution for the flat rolling process with a through height resolution is insufficient. The shear evolution is part of the deformation path and describes the path dependent shear [42] induced by the flat rolling process. Path dependent indicates that in addition to the amount, also the direction of the deformation is considered along the path. Figure 1 schematically illustrates this for a surface element. Without considering the direction, the accumulated shear in Fig. 1c would increase further after the neutral point.

a Roll gap area above the symmetry plane enlarged. The surface element with direct contact to the work roll is emphasized for a few positions along the rolling direction \({x}_{RD}\). The remaining elements over the rolling stock height are not shown. The shear induced by the flat rolling process extends from the contact area to the center of the rolling stock. b Oversimplified surface element state for each rolling position enlarged with neglected rotation and height \(h\) change. The initially undeformed quadrilateral element shears due to the frictional shear stress \({\tau }_{R}\) between the contacting surfaces. This stress \({\tau }_{R}\) can be divided into positive- \({\tau }_{R,+}\) and negative frictional shear stress \({\tau }_{R,-}\) applying forward and backward shear, respectively. The arrow above the element shows the shear direction. The symbol within the shear represents the amount of accumulated shear corresponding to the curve shown in (c). Circle refers to no shear and plus to positive shear. A bigger symbol indicates a higher shear state. c Oversimplified shear evolution for the considered surface element along the rolling direction \({x}_{RD}\)

The shear evolution can usually be neglected for rolling applications where integral rolling values are of interest or the uniform deformation, i.e., plane strain condition without shear, is applicable. The assumption of uniform deformation holds for some applications for the rolling stock center [43, 44]. This is typically not the case closer to the rolling stock surface.

The effect of the shear usually increases from the center to the surface of the rolling stock height. As a result, shear consideration might be required even for an accurate determination of integral values like roll force [20] or total equivalent strain [21], which in turn determines the prediction of grain size and recrystallization [23, 38,39,40]. However, in these cases the knowledge about the total equivalent shear (path independent description of shear) after the roll gap is typically sufficient [45].

For rolling application where the microstructure formation depends on the deformation path, the consideration of the shear evolution as part of this path is typically required. In the case of steel, the deformation path influences the austenite-to-martensite phase transformation kinetic, known as TRIP effect [46]. As a result, target values like strength and formability are affected [47, 48]. The deformation path also influences defects as void and central burst in rolling [49,50,51,52]. Defects lead usually to material failure and decreased material performance during service. Furthermore, the deformation paths determines the crystallographic texture in rolling [53,54,55,56,57,58,59]. The control of this texture is important. The crystallographic texture determines e.g. the suitability of aluminum alloys for deep drawing by influencing the non-isotropic formability [60,61,62,63,64] or causes the “paint-brush lines”, defects occurring during forming operations, which are visible in the automotive component after painting [65]. In the case of electrical steel sheets, the crystallographic texture influences the magnetic properties, and therefore the efficiency of the electric component [66, 67]. The shear evolution can thus be of importance for materials whose final properties depend on the deformation path.

Due to the lack of the conventional fast rolling models to consider the shear evolution, slow and complex models typically determine the shear evolution. With this approach, the determination, e.g., of the crystallographic texture even with fast texture models [68,69,70,71,72,73,74] has a high computational cost due to the fact that the slowest model dictates the overall computational effort. Additionally, these fast texture models require the deformation path in different formulations e.g. as strain, deformation-, displacement- or velocity gradient to operate. Therefore, a fast rolling model with shear evolution consideration is required to utilize the advantage of fast texture models with the ability to satisfy all texture models. The authors of this work present an easy and general approach to construct such a fast rolling model for the flat rolling process.

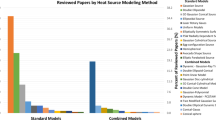

2 Literature review

Over the years a variety of fast models to describe shear during the rolling process emerged. They can be roughly divided into two approaches: continuum mechanics-based or data-based.

The continuum mechanics-based approach derives a model based on physical and mathematical knowledge usually with simplifications. This requires expert knowledge about the domain [75]. In return, a physically based model with a larger scope of validity is obtained in contrast to the data-based approach.

There are many methods to create data-based models [76], curve fitting is one among the best known. Here, a model with unknown parameters is given. The unknown parameters are varied until the model describes the data sufficiently well. The nature of the given model can be anything between empirically or close to physically based. Another well-known data-based approach is the storage of the data as lookup-table usually with an interpolation formulation to create a model. This approach is usually used when there is no suitable physical and mathematical description for the domain or when the description is too complex for practical use [75]. Data-based approaches have generally in common that they produce models with a specific scope of validity. However, such models are in most cases sufficient for repetitive industrial applications.

2.1 Slab model

The slab method [77, 78] is probably the most commonly used continuum mechanics-based approach to create fast rolling models [2]. A model based on this method is labeled in this work as slab model. The popularity of slab models can likely be attributed to the low complexity and the arbitrary extensibility [79,80,81]. In the original version, beginning with the works of Siebel [36] and Karman [82], the deformation is simplified by a homogeneous compression of vertical slabs along the roll gap considering a constant flow stress and neglecting shear. An important extension was made by Orowan [25]. The approach considers a variable flow stress and limits the frictional shear stress \({\tau }_{R}\) between rolling stock and work roll to the shear flow stress.

2.1.1 Analytical equation to extend the slab model

An equation to consider shear along the roll gap induced by the roll gap geometry was presented by Karhausen [83]. The aim of the author was the prediction of integral rolling target and microstructure values like dynamic recrystallization and the evolving grain size. For this purpose, the shear equation was fully integrated in the slab model to improve the prediction of the total equivalent strain over the rolling stock height along the rolling direction \({x}_{RD}\). The introduced shear model calculates the roll gap geometry induced shear at the surface between the work roll and the rolling stock by an incremental comparison of the height \(h\) change of the vertical slab between time increments \(i\) and \(i+1\). The author assumes a linear distribution of the calculated shear over the rolling stock height and neglects the shear induced by the frictional shear stress \({\tau }_{R}\). The author states a satisfactory prediction of the shear for rolling cases with a roll gap ratio \({l}_{c}/{h}_{m}>1.8\) (projected arc length of contact \({l}_{c}\) divided by mean rolling stock height \({h}_{m}={(inital \,height }\,h_{0}+{final \,height}\, h_{1})/2\) and a small Coulomb friction coefficient. The influence of the shear increases for rolling cases with roll gap ratios \({l}_{c}/{h}_{m}<1.8\) due to the higher roll bite angle \({\alpha }_{b}\) (angle between the work roll radius vectors to the roll gap entry and -exit). According to the author, the shear model cannot predict these cases well. The author used the calculated shear to determine the total equivalent strain and compared these to finite element (FE) simulations. The shear strain component was not analyzed on its own. Rolling cases with large roll gap ratios \({l}_{c}/{h}_{m}\) are considered due to the validity range of the shear model. The author explains the deviations of the total equivalent strain between the calculations and the FE simulations by the neglected shear induced by the frictional shear stress \({\tau }_{R}\). According to the author, the quality of the calculated total equivalent strain is sufficiently well for the pursued aim.

2.1.2 Data-based extension of the slab model

Seuren et al. [84] presented a data-based approach with the aim to improve the total equivalent strain prediction over the rolling stock height for hot plate rolling of C-Mn steel. They derived based on FE simulations an analytical equation to consider shear and combined it with the slab model to predict the total equivalent strain after the roll gap exit. 2D plane strain hot plate rolling simulations were performed as foundation for the analytical equation. They considered roll gap ratios \({l}_{c}/{h}_{m}\) and initial rolling stock heights \({h}_{0}\) between \(1<{l}_{c}/{h}_{m}<6.7\) and \(5\, \text{mm}< {h}_{0}<900 \,\text{mm}\), respectively. Additionally, a fix Coulomb friction coefficient of \(\mu =0.35\) was considered. They used the shear strain after the roll gap exit as data to derive the analytical equation. It can be inversely obtained, if the total equivalent strain after von Mises [21] and the normal strain are known. They extracted the total equivalent strain from the FE simulation and calculated the normal strain for the roll gap exit based on the total height reduction \({e}_{h}= {(h}_{0}-{h}_{1})/{h}_{0}\cdot 100\) of the rolling stock. For the inversely determined shear strain, regressions were performed with the symbolic regression program called Eureqa [85] described by Schmidt and Lipson [86] to find suitable analytical equations. The authors identified two different total equivalent strain profiles; each independently described with an analytical equation and linked together with a weighting function. Since the total equivalent strain represents an integral scalar value, the obtained shear strain can be interpreted as total equivalent shear strain. As a result, it is always positive, a negative- or backward shear cannot be described. Especially for small roll gap ratios \({l}_{c}/{h}_{m}\) as shown in the work of Seuren et al., a relevant negative shear is observable. However, the authors achieved their aim to describe the total equivalent strain. The results of the presented model are compared to FE simulations.

2.1.3 N-Layer slab model

Schmidtchen and Kawalla [87] went a step further and introduced an approach to improve the slab model in general regarding the prediction accuracy. The approach can be interpreted as a mixture of continuum mechanics and data-based. The data-based part compensates the underlying simplifications of the slab model regarding homogeneous compression and shear. According to the authors, the model achieved an improvement of the total equivalent strain prediction over the rolling stock height compared to the unmodified slab model. They used the two-layer model presented by Zhang and Bay for roll bonding [88] to improve the slab model. The two-layer model divides the rolling stock height along the normal direction \({y}_{ND}\) in two different layers. Each layer has a different height \(h\) and strength. As a result, the deformation over the rolling stock height is not homogeneous. The authors applied the two-layer concept to the slab model and extended the number of layers from two to N-layers. A semi-empirical equation with a local friction consideration predicts the height \(h\) change of each layer. As a result, according to the authors, the shear in the roll gap induced by the roll gap geometry and the frictional shear stress \({\tau }_{R}\) is determinable. The semi-empirical equation requires a fitting based on data to predict the height \(h\) change and the local friction of each layer. For this purpose, a set of first-order differential equations needs to be solved. According to the authors, the equations strongly depend on several internal parameters, especially on the position of the neutral point for each layer. The N-layer slab model is solved numerically due to the high complexity, whereby according to the authors a convergence is not guaranteed. The authors performed a cold rolling FE simulation as an example with a rigid plastic material behavior for the rolling stock to show the accuracy of the model regarding the deformation prediction. They scheduled a full comparison of the N-layer slab model with FE simulations and experimental results for their following paper, which has not been published yet, to investigate the deformation prediction and therefore the shear.

2.2 Velocity field-based model

Another common approach for the rolling process is the description of the velocity field. An appropriate velocity field enables the calculation of local- (e.g. shear) and integral rolling values (e.g., roll force). The upper bound method [89, 90] is usually applied to derive rolling target values based on the velocity field. Many authors [91,92,93,94,95] applied this method to derive integral rolling target values like roll force, torque or total equivalent strain. However, to be able to apply the upper bound method, the velocity field does not need to describe the real material flow. Therefore, the calculation of local values like shear based on the proposed velocity fields is questionable. However, a suitable velocity field enables the calculation of local values. Due to this fact, the velocity field description has been studied. The investigations are presented in the following.

2.2.1 Adaptation of a drawing model to determine the shear angle \(\alpha\)

Lachmann and Zouhar [96] presented a velocity field model for the plane strain condition with the purpose to investigate the inhomogeneous deformation over the height \(h\) induced by shear. The model describes the total equivalent strain over the rolling stock height for the hot flat rolling process. The presented model is an adaption of the velocity field model previously presented by Eder [97] for drawing. Due to the origin, the presented model assumes the curvature of the work roll in contact with the rolling stock to be a line, starting at the initial rolling stock height \({h}_{0}\) and ending at the final rolling stock height \({h}_{1}\). It neglects the direction change of the frictional shear stress \({\tau }_{R}\) induced by the forward slip zone and assumes a mean frictional shear stress \({\tau }_{R}\) along the contact area. An initial square net grid can be deformed by applying the velocity field model, which enables the validation of the model results by visioplastic experiments [98, 99]. Due to the velocity field, the vertical straight-line of the initial square net grid bends monotonously in the roll gap towards the rolling direction \({x}_{RD}\). This results in a curvature of the vertical straight-line with a maximum bending at the surface. This behavior can be interpreted as shear induced by the frictional shear stress \({\tau }_{R}\). Therefore, it can be assumed that the validity of the model holds for rolling cases with large roll gap ratios \({l}_{c}/{h}_{m}\), where the frictional shear stress \({\tau }_{R}\) can be identified as dominating influence for shear [100]. The backward shear observed by Sakai et al. [101], especially due to the influence of the forward slip zone, cannot be described by the model according to the authors. The authors [102] investigated based on the presented model the total equivalent strain during the hot flat rolling process for an unalloyed C-Mn steel. They conducted visioplastic experiments for large roll gap ratios \({l}_{c}/{h}_{m}>2.57\) on a laboratory rolling mill. The cross-sectional net of the initially applied square net grid was compared to the calculated net based on the velocity field model. The authors deduced that the agreement between measured and calculated net is insufficient in the first two thirds of the roll gap but good afterwards. The bent vertical line after the roll gap exit is characterized by measuring the curvature angle called shear angle \(\alpha\) over the rolling stock like shown in Fig. 2.

The \(shear\, strai{n}_{s}=\mathit{tan}\left(shear \,angle \,{\alpha }_{s}\right)\) is determined based on the measured shear angle \({\alpha }_{s}\) according to the small deformation assumption [103] over the rolling stock height and used directly to calculate the total equivalent strain. The authors explain the deviation of the total equivalent strain between the experiment and the model by the neglected backward shear. According to the author, the quality of the calculated total equivalent strain is sufficient.

2.2.2 FE simulation to determine the shear angle \(\alpha\)

A similar procedure was presented by Mukhopadhyay et al. [104]. They also analyzed the deformed net grid after the roll gap exit to obtain the shear angle \(\alpha\) and the shear strain with the same procedure used by Lachmann and Zouhar. Instead of a velocity field description, FE simulations were carried out. Additionally, their aim was the improvement of the total equivalent strain prediction by considering shear with the capability to be applied to automated rolling control. This kind of application requires a model with real time capability. They applied a lookup-table approach to create such a model. The lookup-table contains 2D plane strain hot plate rolling simulations results for 316L stainless steel (1.4404). The considered roll gap ratios \({l}_{c}/{h}_{m}\) are \(0.5<{l}_{c}/{h}_{m}<3\) with a fix Coulomb friction coefficient of \(\mu =0.577\). They analyzed the deformed mesh of the rolling stock after the roll gap exit for a steady state region. In comparison to Lachmann and Zouhar, only an average shear angle \(\alpha\) and average shear strain are calculated to reduce the amount of data. According to the authors, the shear strain values can be provided to an automated rolling control to consider shear. The identification of the shear angle \(\alpha\) after the roll gap exit neglects some shear information. Through this, an accumulated shear angle \(\alpha\) of zero can be identified after the roll gap exit due to the counteracting of the forward and backward shear. This influences also the accuracy of the predicted total equivalent strain. However, they presented a fast and easy concept to derive the shear information from FE simulations.

2.2.3 Streamline approach with velocity gradient

Decroos et al. [41] presented in their work another approach compared to Lachmann and Zouhar to derive the velocity field to consider shear. The model is intended to describe the inhomogeneous deformation over the rolling stock height along the rolling direction \({x}_{RD}\). They used the streamline approach [103] as foundation, where the material flows along streamlines. The velocity field for the rolling process can be calculated by considering different streamlines over the rolling stock height. The authors modified the streamline approach to consider the variation of the material flow velocity along the streamlines. They introduced equations to describe the velocity distribution between the surface and the center of the rolling stock. The equation parameters are dependent on the material property, temperature and friction conditions. According to the authors, the parameters can be fitted by comparing the deformed vertical lines after the roll gap exit determined by experiments and calculated by the velocity field model. Additionally, the neutral point needs to be determined. In the work of the authors, the neutral point was arbitrarily chosen to be half of the projected arc length of contact \({l}_{c}\). The presented model considers the shear induced by the roll gap geometry and by the frictional shear stress \({\tau }_{R}\). The fitting of the equation parameters based on the deformed vertical line after the roll gap exit leads to an inaccurate prediction of the shear along the roll gap for some rolling cases. The reason is the shear canceling due to the forward and backward shear within the roll gap. Furthermore, the model relies on the prediction of the neutral point. The prediction of the neutral point is challenging in general but particularly critical, if there is a distinct sticking friction zone. The calculated deformation over the rolling stock height of the model is compared to the results of an FE simulation performed by Engler et al. [105]. According to the authors, the deviations to the FE results are up to three times higher but a good qualitative agreement is achieved.

2.2.4 Mixture of neural network and Eulerian FE method

Another approach was presented by Gudur et al. [106]. They tried a mixture of neural network and Eulerian FE method to describe the velocity field for the cold flat rolling process with the aim of providing a fast alternative to classical FE simulations. The data to train the neural network was generated by a rigid-plastic Eulerian FE formulation introduced by Dixit [107] for plane strain. The formulation presented by Dixit requires the knowledge of the neutral point location. The slab model initially guesses the location and the upper bound method optimizes it, afterwards. The equivalent strain field is calculated by the Eulerian FE formulation for an initial velocity field by integrating the velocity along the streamlines [108]. The procedure calculates a flow stress field based on the equivalent strain field and determines afterwards a new velocity field. This repeats until convergence is achieved. The applied power law for the flow stress description considers only strain hardening. The authors carried out a rolling study to generate a data set to train the neural networks. They extracted for each rolling case the velocity value for 6 out of 256 nodes and the neutral point location. The authors trained with the data for each velocity direction an independent neural network and additional one for the neutral point. The prediction of the neural networks serves the Eulerian FE formulation as initial estimation. This reduces the number of iterations to reach convergence and as a result also the calculation time. To the authors of this study it is not completely clear, why the estimation step is required. It could be that due to the reduced consideration of only six nodes to train the neural networks, the prediction of the velocity field requires the convergence step to reach enough accuracy. However, this procedure has some advantages. Different rolling target values like roll force, pressure distribution or strain–stress field can be calculated by the formulation after convergence. The prediction time of the neural network is within seconds but the post processing calculation based on the Eulerian FE formulation takes some minutes. The approach reduced the calculation time for the considered rolling case according to the author to one tenth compared to the Eulerian FE formulation without the assistance through the neural networks. However, the computation effort of this approach is not competitive with fast rolling models, even with the significantly reduced calculation time.

2.2.5 Data-based sinus-shaped function

A simple sinus-shaped function to describe the shear evolution along the rolling direction \({x}_{RD}\) induced by the roll gap geometry and the frictional shear stress \({\tau }_{R}\) was presented by Engler et al. [105]. Their aim was the investigation of the influence of different shear states at the texture prediction by means of the viscoplastic self-consistent (VPSC) polycrystal deformation model. The model presented by Engler et al. was inspired by Huh et al. [109], which is an extension of the simple analytical model presented by Lee and Duggan [42]. The model by Engler et al. assumes a constant height \(h\) change along the rolling direction \({x}_{RD}\). They set the neutral point to the middle of the projected arc length of contact \({l}_{c}\) and described both shear evolutions individually by a sinus-shaped function. The amplitudes of these functions are fitted based on the total equivalent shear results obtained by the FE simulation. As a result, the model can be categorized as a data-based model. According to the authors, the application of the model is intended for rolling cases with roll gap ratios \({l}_{c}/{h}_{m}>1\) due the assumed simplifications. The neutral point is typically not located in the middle of the projected arc length of contact \({l}_{c}\) especially in the case of a distinct sticking friction zone. Furthermore, the integrated shear along the rolling direction \({x}_{RD}\) is always zero at the roll gap exit. As a result, the shear induced bending of an initially vertical straight line as observed by other authors cannot be described. The authors performed a rigid-plastic FE simulation with a roll gap ratio \({l}_{c}/{h}_{m}=1.7\) for low-carbon steel to validate the model.

3 Specific goal and -procedure

There are approaches for a fast description of the shear evolution along the rolling direction \({x}_{RD}\) for the flat rolling process. They are usually designed only for specific rolling cases, e.g., for large roll gap ratios \({l}_{c}/{h}_{m}\) or for cold rolling. Some approaches neglect influencing factors, such as the frictional shear stress \({\tau }_{R}\). Approaches that determine the shear using the visioplastic method after the roll gap exit cannot provide a meaningful statement about the shear evolution along the roll gap. The information about the amount and direction of the backward and forward shear is no longer available at the roll gap exit. Others rely on the prediction of the neutral point to predict the shear. The prediction of the neutral point is in general difficult but particularly critical in the case of a distinct sticking friction zone.

3.1 Specific goal

The goal of this work is to provide an easy and general approach to enable fast rolling models to consider the shear evolution. This approach represents a combination of continuum mechanics and data-based. The approach considers the shear evolution caused by the roll gap geometry and by the frictional shear stress \({\tau }_{R}\). It describes the amount and the direction of the forward and backward shear along the rolling direction \({x}_{RD}\) over the rolling stock height. The approach is applicable to all rolling cases without restrictions regarding roll gap ratio \({l}_{c}/{h}_{m}\), temperature and rolled material. This includes the applicability even in the presence of a distinct sticking friction zone. The approach is comprehensible and not a black box like the artificial neural network. It preserves the advantages of the fast rolling model regarding short computation time and low complexity. Additionally, the approach enables the calculation of each deformation value (strain, deformation-, velocity gradient, etc.) required by texture models to operate.

3.2 Specific procedure

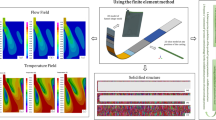

The idea to derive the shear evolution along the rolling direction \({x}_{RD}\) is based on the knowledge from continuum mechanics that the element nodal coordinates can be used to determine the shear evolution. Therefore, the element nodal coordinates of an FE rolling simulation contain the information about the shear evolution. However, an FE rolling simulation is complex and slow for real time applications. The aim is therefore to derive the shear evolution from the complex and slow FE rolling simulation and to provide the possibility to extend a fast rolling model. Figure 3 schematically shows the idea.

Concept to derive the shear by evaluating the element nodal coordinates \(N{:=}\left\{{N}_{i}={\left({x}_{i} {y}_{i}\right)}^{T}| i\in \left\{1,\dots ,4\right\}\right\}\) of the FE simulation. The element nodal coordinates \(N\) are extracted after the FE simulation along the rolling direction \({x}_{RD}\) to determine the shear. For each element, the abscissa of a local Cartesian co-rotational coordinate system is aligned to the bottom edge of the element connected by the nodes \({N}_{1}\) and \({N}_{2}\) with the origin set on the node \({N}_{1}\). The angle between the local Cartesian co-rotational coordinate system and the element describes the shear and is defined as shear angle \(\alpha\). The shear angle \(\alpha\) evolution is obtained by determining the shear angle \(\alpha\) along the rolling direction \({x}_{RD}\). The procedure is shown for the surface element as an example but is applicable to each element over the rolling stock height

The rolling process causes a complex deformation of the material along the rolling direction \({x}_{RD}\). The main challenge in determining the shear angle \(\alpha\) is the continuous displacement and rotation of the element. To deal with the rotation, the local Cartesian co-rotational coordinate system described by Aukrust et al. [110] for the extrusion process based on the velocity field is adapted and applied to the element nodal coordinates \(N\). The benefit of the local Cartesian co-rotational coordinate system is the ability to rotate with the element along the rolling direction \({x}_{RD}\). For this paper, the application of the local Cartesian co-rotational coordinate system enables the determination of the shear angle \(\alpha\) along the rolling direction \({x}_{RD}\) in comparison e.g. to Lachmann and Zouhar, where the shear angle \(\alpha\) was only determined after the roll gap exit. By applying the procedure, post-processing based on the element nodal coordinates \(N\) is possible without any modifications to the simulation. Therefore, the procedure can be applied to existing simulation results, which presents a huge advantage. Shear evolutions are available by obtaining the shear angle \(\alpha\) along the rolling direction \({x}_{RD}\). As a result, the shear information is derived from the complex and slow FE rolling simulation and available as a simple angle evolution with a rolling stock height resolution. The shear angle \(\alpha\) represents a rotation-free value, which is compatible with established fast rolling models such as the slab model. Extending the slab model as an example with the shear angle \(\alpha\) evolution generates the \(\alpha\)-\(h\)-Model. This enables a complete description of the deformation path. With the continuum mechanics, each desired deformation value (e.g., strain, deformation gradient) can be derived based on the deformation path. This also allows the calculation of the shear evolution. Due to the nature of the data-based approach, the validity of the obtained shear angle \(\alpha\) evolution has a dependency on the material properties. Therefore, if the properties of a new material significantly diverge compared to the original material, a new determination of the shear angle \(\alpha\) evolution is required. This has no influence on the presented approach. It remains the same. FE hot rolling of aluminum is selected to demonstrate the applicability of the procedure due to the extreme conditions. This process is known for a high friction resulting in higher frictional shear stress \({\tau }_{R}\) compared to cold rolling. Furthermore, also a distinct sticking friction zone can be observed.

The work is structured as follows. Section 4 provides the theoretical background regarding the deformation calculation. Section 5 discusses the deformation phenomena of the rolling process. Section 6 presents the FE process model and the material properties used to determine the shear angle \(\alpha\) evolution. Section 7 describes the specific procedure to calculate the shear angle \(\alpha\) evolution based on the FE simulation results. Afterwards, Sect. 8 presents a routine to investigate the deformation phenomena along the rolling direction \({x}_{RD}\) to emphasize the benefit of the shear angle \(\alpha\) evolution. Section 9 introduces the combination of the classical slab model and the \(\alpha\)-lookup-table to construct the fast rolling model labeled as \(\alpha\)-\(h\)-Model. Afterwards, Sect. 10 introduces a reference model to compare the results of the \(\alpha\)-\(h\)-Model. At the end, Sect. 11 compares the calculated results to FE simulation results.

4 Theory of the deformation calculation

This section briefly introduces some basic continuum mechanics topics regarding deformation for a better understanding of the work. The continuum mechanics related mathematical notation in this work is leaned on Bertram [111]. For the sake of simplicity, a bold character highlights a tensor and the term “tensor” is omitted.

4.1 Reference and current configuration

The displacement \({\varvec{u}}\) describes the difference between position vectors of a material point. In the case of an isoparametric quadrilateral element (Fig. 4), this displacement \({\varvec{u}}\) can be determined as element displacement \({\varvec{u}}\) by the shape function [112] between two given configurations.

Deformation of an element. Both configurations represent quadrilateral elements each described by element nodal coordinates \(N:=\left\{{N}_{i}={\left({x}_{i} {y}_{i}\right)}^{T}|i\in \{1,\dots ,4\}\right\}\), emphasized by gray dots. The reference configuration can be an undeformed or deformed element. The current configuration represents the element after a deformation increment. The element displacement \({\varvec{u}}\) describes the displacement between both configurations

The deformation gradient \({\varvec{F}}\) can be determined based on the element displacement \({\varvec{u}}\) and decomposed according to Eq. 1 [111] and Eq. 2 [113], respectively.

Equation 1: Deformation gradient \({\varvec{F}}\) as derivative of the element displacement \({\varvec{u}}\) after the reference configuration \({\varvec{X}}\). \({\varvec{I}}\) represents the identity.

The right stretch \({\varvec{U}}\) in Eq. 2 describes the shape change and \({\varvec{R}}\) the rotation part of the deformation. By means of the right stretch \({\varvec{U}}\), every desired strain value can be calculated.

Equation 2: Decomposition of the deformation gradient \({\varvec{F}}\) by means of the polar decomposition into rotation \({\varvec{R}}\) and right stretch \({\varvec{U}}\).

The Hencky strain \({{\varvec{E}}}^{H}\) shown in Eq. 3 is such a strain value, introduced for large deformation [114, 115]. This value represents true strain, often used in forming technologies and by FEM.

Equation 3: Formula to calculate the Hencky strain \({{\varvec{E}}}^{H}\) based on the right stretch \({\varvec{U}}\). The log-function applied to get the Hencky strain \({{\varvec{E}}}^{H}\) is the principal matrix logarithm function with a different definition as the usually known one [116].

The shear can be derived according to Eq. 4.

Equation 4: Formula to calculate the shear \(shear {{\varvec{E}}}^{H}\) based on the determined Hencky strain \({{\varvec{E}}}^{H}\).

4.2 Total and updated Lagrangian formulation

The choice of the reference configuration is arbitrary and has an impact on the calculated deformation gradient \({\varvec{F}}\). Figure 5 shows two ways to select this configuration typically used in FEM. They are labeled with total and updated Lagrangian formulation [111].

Deformation evolution of a quadrilateral element, described by two different Lagrangian formulations. Gray dots emphasize the element nodal coordinates \(N\) for each element. The element nodal coordinates \(N\left({x}_{0}\right)\) for the initial position \({x}_{0}\) are deformed into \(N({x}_{1})\) and afterwards into \(N({x}_{2})\). The element nodal coordinates \(N\left({x}_{0}\right)\) and \(N\left({x}_{2}\right)\) describe the same element shape

The total Lagrangian formulation uses the same configuration, usually the initial one, as the reference configuration to obtain the deformation gradient \({\varvec{F}}\). In comparison, the updated Lagrangian formulation uses the previous configuration and therefore describes the path dependent change of the element. As a result, the calculated deformation gradients \({{\varvec{F}}}_{2}^{tot}\) and \({{\varvec{F}}}_{2}^{up}\) differ for the same deformation. Furthermore, the total Lagrangian formulation in Fig. 5 determines the deformation between the element nodal coordinates \(N({x}_{0})\) and \(N({x}_{2})\) as zero in comparison to the updated Lagrangian formulation. The deformation gradient \({\varvec{F}}\) determined by the total Lagrangian formulation does not directly describe the path dependent deformation but the information can be derived by further calculation steps [111], neglected here. As a result, both formulations are equivalent. They describe the deformation only from different perspectives.

To describe the strain also path dependent, the rotation \({\varvec{R}}\) part of the deformation gradient \({\varvec{F}}\) needs to be considered according to Eq. 5 also applied by FEM [112, 117].

Equation 5: Accumulation of the Hencky strain with respect to the updated Lagrangian formulation. \({{\varvec{E}}}_{i-1}^{H}\) and \({{\varvec{E}}}_{i}^{H}\) correspond to the accumulated Hencky strain for the previous and current element nodal coordinates \(N\left({x}_{i-1}\right)\) and \(N({x}_{i})\), respectively. \({\Delta {\varvec{R}}}_{i}\) and \(\Delta {{\varvec{U}}}_{i}\) are decomposed according to Eq. 2 based on the incremental deformation gradient \({{\varvec{F}}}_{i}\), calculated for both configurations.

The accumulated Hencky strain \({{\varvec{E}}}_{i-1}^{H}\) of the previous calculation is rotated with respect to the current incremental rotation \({\Delta {\varvec{R}}}_{i}\). Afterwards, the incremental Hencky strain \({\Delta {\varvec{E}}}_{i}^{H}\) of the current calculation can be added to obtain the path dependent strain.

5 Deformation phenomena in the rolling process

This section briefly discusses the relevant deformation phenomena along the roll gap for the plane strain condition, i.e. the transverse direction \({z}_{TD}\) is neglected.

5.1 Simple shear shapes

The continuum mechanics knows two shear types, which can occur in general: the simple and the pure shear [111]. The main difference: the simple shear does contain rotation and the pure shear does not. The following discusses only the simple shear due to the relevance for this work. Figure 6 shows four shapes of simple shear.

Simple shear illustrations. The arrow on the element indicates the shear direction. Two shapes overlap each other, where the dashed one shows the original shape and the solid one shows the sheared shape. S1− (negative in y-direction) and S2− (negative in x-direction) represent the negative shear and S3 + (positive in y-direction) and S4 + (positive in x-direction) represent the positive shear

The shapes indicate positive- and negative shear. The sign is just a convention depending on whether the shape is sheared in the direction of the respective axis or against it. A combination of the simple shear shapes is also possible. This work uses the same sign convention as Abaqus Standard for an isoparametric element with respect to a global coordinate system [117]. This enables the interpretation of the Abaqus Standard simulation outputs later in the result Sect. 11. Abaqus Standard serves only as example. The method can also be applied to any other FEM software.

With the definition of the simple shear shapes (Fig. 6), the deformation phenomena for a surface element with direct contact to the work roll are analyzed. For this purpose, Fig. 7 presents an idealized shear evolution for an initially undeformed surface element, decomposed into shear and rotation. The following describes in detail the four rows: shear state caused by roll gap geometry and frictional shear stress \({\tau }_{R}\), element- and material rotation.

Idealized shear evolution of a surface element with direct contact to the work roll decomposed into shear and rotation. The surface element is highlighted for few rolling positions \(x\) along the rolling direction \({x}_{RD}\). The analysis is simplified by neglecting the height \(h\) change, the elastic deformation phenomena and the plastic deformation phenomena outside of the roll gap. The first two rows show the shear induced by the roll gap geometry and the frictional shear stress \({\tau }_{R}\) [42]. The last two rows show the element- and material rotation induced by shear [118, 119] attached with a local coordinate system to emphasize the rotation. Remark: For the undecomposed case, the frictional shear stress \({\tau }_{R}\) is directed in the tangential direction of the roll due to the superimposed rotation. Shear and rotation have their origin at the contact area but the effect can extend from the contact area to the center of the rolling stock. The arrow on the element indicates the dominant shear direction. The symbol within the element indicates the current accumulated amount of shear. A bigger symbol refers to a larger quantitative amount of shear in the sheared direction. The minus symbol indicates a negative, the plus symbol a positive and the circle symbol a neutral shear state

5.2 Roll gap geometry and frictional shear stress \({\tau}_{R}\) induced shear

The roll gap geometry describes the geometry-related shear, depending on the roll gap ratio \({l}_{c}/{h}_{m}\). It induces at the roll gap entry the negative shear S1-. The shear decreases along the rolling direction \({x}_{RD}\) and is neutral at the roll gap exit. This can be attributed to the fact that at roll gap entry the roll bite angle \({\alpha }_{b}\) between the work roll and the rolling stock is high and decreases along the rolling direction \({x}_{RD}\) until it reaches the value zero at the roll gap exit. Therefore, shear by the roll gap geometry is most dominant in the area around the roll gap entry.

The frictional shear stress \({\tau }_{R}\) describes the shear induced through the friction between the work roll and the rolling stock. It induces at the roll gap entry the positive shear S4 + . This shear increases through the positive frictional shear stress \({\tau }_{R,+}\) until the neutral point. The reversed frictional shear stress \({\tau }_{R,-}\) after the neutral point applies the negative shear S2−. This reduces the positive shear, which may result in three possible shear states at the roll gap exit (compare Fig. 7, second row). For the positive shear state, the forward slip zone is too short or the negative shear induced is too small to reduce the positive shear completely. The opposite applies to the negative shear state. For the neutral shear state, the positive- and negative shear cancel each other out.

5.3 Element and material rotation

Deformation induces rotation [111]. This rotation can be decomposed into different kind of rotations, affecting the material on the macroscopic and microscopic scale [120,121,122,123]. This work focuses on the element- and material rotation. They are sufficient to describe the deformation completely. At the roll gap entry, the element experiences element- and material rotation indicated in Fig. 7 by the local coordinate system attached to the element.

The element rotation is a pure rigid-body rotation and has no effect on the deformation but it changes the perspective of the observer. It can be therefore relevant for some cases, e.g., for the interpretation of the measured macro texture. The element rotates through the entry into the roll gap. The amount of element rotation is high at the roll gap entry and decreases along the rolling direction \({x}_{RD}\) due to the decreasing intermediate roll bite angle \({\alpha }_{b,x}\) (angle between the work roll radius vectors to the rolling position \(x\) and roll gap exit). At the roll gap exit, the intermediate roll bite angle \({\alpha }_{b,x}\) is zero. The element is aligned again with the global coordinate system and thus the element rotation is completely canceled.

Even though the element rotation has no effect on the deformation, it influences the calculation of the strain by means of the updated Lagrangian formulation. The element rotation is part of the incremental rotation \(\Delta {{\varvec{R}}}_{i}\) applied in Eq. 5 to rotate the strain. Therefore, neglecting the element rotation would result in a different calculated Hencky strain \({{\varvec{E}}}^{H}\). However, the Hencky strain \({{\varvec{E}}}^{H}\) would still describe the same deformation.

In comparison to the element rotation, the material rotation has an effect on the deformation and is relevant for the texture due to its influence on the grain orientation [124,125,126]. Figure 8 illustrates the source of the material rotation.

Deformation of an element due to simple shear S4 + . The shear is indicated by \({x}_{1}\). The element experiences no element rotation. The element height \({y}_{0}\) is unchanged and the element does not show any sign of rotation. However, due to the simple shear the rotation \({\varvec{R}}\) after the polar decomposition of the deformation gradient \({\varvec{F}}\) is not equal to identity and thus not zero

The material rotation depends on the shear and as a result can remain after the roll gap exit. Therefore, three possible material rotation states after the roll gap exit are possible as shown in Fig. 7 (bottom row).

6 Description of the FE process model

This work investigates the shear evolution by means of a 2D plane strain temperature displacement coupled hot rolling model in Abaqus Standard. The detailed parametric setup of this model is described by Hojda [127]. Abaqus Standard serves in this work only as an example; any other FEM software can also be used. The model has a symmetry plane in transverse- \({z}_{TD}\) and rolling direction \({x}_{RD}\) as symmetry boundary condition. As a result, only the part above the symmetry plane of the schematically shown Abaqus Standard model in Fig. 9 was simulated to reduce calculation time. The model contains three parts: work roll, rolling stock and pusher.

Schematic illustration of the Abaqus Standard rolling model with the material and mesh properties highlighted for the parts: pusher, rolling stock and work roll. Following values are indicated: the roll bite angle between the roll gap entry and -exit \({\alpha }_{b}\); the intermediate roll bite angle between the rolling position \(x\) along the rolling direction \({x}_{RD}\) and the roll gap exit \({\alpha }_{b,x}\); the coefficients of the heat transfer \({\alpha }_{c}\) and the emissivity \(\varepsilon\); the total height reduction \({\varepsilon }_{h}\); the initial- \({h}_{0}\) and final rolling stock height \({h}_{1}\); the element edge length of the rolling stock \({l}_{EL}\); the projected arc length of contact \({l}_{c}\); the normal stress \({\sigma }_{N}\); the positive- \({\tau }_{R,+}\) and negative frictional shear stress \({\tau }_{R,-}\); the temperatures of the work roll \({T}_{{roll}}\) and the rolling stock \({T}_{{stock}}\); the velocities of the pusher \({v}_{{pusher}}\) and the work roll \({v}_{{roll}}\); the outer- \({r}_{{roll}}\) and the inner work roll radius \({r}_{i}\). \(s\) describes the rolling stock position from the center (\(s=0)\) up to the surface \((s=1)\). The reference region defines the evaluation section

6.1 The rolling stock

The rolling stock was modeled as deformable 2D planar. The simulated rolling stock height is \({h}_{0}/2\). The total height reduction \({\varepsilon }_{h}\) is calculated according to Eq. 6.

Equation 6: Formula to calculate the total height reduction \({\varepsilon }_{h}\) of the rolling stock induced by the work roll, neglecting elastic deformation effects.

The projected arc length of contact \({l}_{c}\) to the work roll can be determined according to Eq. 7.

Equation 7: Formula to calculate the contact length between the work roll and the rolling stock based on geometrical considerations, neglecting work roll flattening [37], as projected arc length of contact \({l}_{c}\).

The roll gap ratio \({l}_{c}/{h}_{m}\) can be calculated afterwards according to Eq. 8.

Equation 8: Formula to calculate the roll gap ratio \({l}_{c}/{h}_{m}\) for the rolling process.

A linear notation describes the rolling stock position \(s\) along the normal direction \({y}_{ND}\). The rolling process is in a steady state, at the time the reference region enters the roll gap. The element mesh type is 2D quadrilateral solid continuum coupled with temperature-displacement (CPE4T).

Hydro Bonn Aluminium R&D provided the material properties conductivity, density and heat capacity of an aluminum alloy of the class AA8XXX for the temperature range of 20 °C up to 600 °C. Young’s modulus; Poisson’s ratio and dissipation factor were set to 71,000 MPa; 0.33 and 0.9, respectively. The user subroutine UHARD controls the hardening behavior of the rolling stock. It incorporates a modified Version of the generalized VOCE law introduced by Tome et al. [128].

6.2 The work roll

The work roll was modeled as deformable 2D planar circular ring to enable heat transfer and constrained with a rigid-body constraint to obtain a rigid-body behavior. A rigid-body part in Abaqus Standard is otherwise unable to simulate heat transfer. It is worth mentioning that for very small total height reductions \({\varepsilon }_{h}\) and for some cold rolling cases, the work roll must be modelled as elastic-body. In addition, Eq. 7 must be adapted for these cases. The modelling as ring reduces the number of elements and as a result the simulation time. The element mesh type is CPE4T.

The work roll has the material properties conductivity, density and heat capacity of the steel alloy X5CrNi18-10 (1.4301) for a temperature range of 20 °C up to 200 °C.

6.3 The pusher

The pusher was modeled as rigid 2D planar. The element mesh type is 2D rigid (R2D2).

6.4 Interaction properties

The user subroutine FRIC (description of the friction behavior) describes the isotropic tangential contact behavior between work roll and rolling stock. Within this subroutine the combined friction model [25] according to Eq. 9 with the penalty friction formulation [117] was implemented in Fortran and coupled with Abaqus Standard.

Equation 9: Formula to calculate the critical frictional shear stress \({\tau }_{crit,R}(x)\) between the contacting work roll and rolling stock surface. The stress \({\tau }_{crit,R}(x)\) is determined for each rolling position \(x\) along the rolling direction \({x}_{RD}\). \(m\) describes the friction factor and \(k\) the shear flow stress at the rolling stock surface calculated based on the total equivalent strain after von Mises [21].

The friction model (Eq. 9) corresponds to an inhomogeneous description of the Coulomb friction coefficient \(\mu\) along the rolling direction \({x}_{RD}\) as described by Pawelski [129]. The heat transfer coefficient \({\alpha }_{c}\) between work roll and rolling stock was set to \(13\cdot {10}^{-3}\,\mathrm{W}/({\mathrm{mm}}^{2}\cdot K)\) at direct contact and decreases linear to zero up to the clearance of 0.25 mm for an easier numerical contact establishment. Between the rolling stock and the pusher, hard contact normal behaviors with the penalty constraint and a frictionless tangential contact behavior were chosen.

7 Determination of the shear

This section presents the method to determine the shear angle \(\alpha\) evolution based on FEM simulation. The shear angle \(\alpha\) determined by the method is a geometrical description of the element deformation. Therefore, it is not affected by the rotations mentioned in Sect. 5.3. This enables the use of the shear angle \(\alpha\) in combination with other rotation-free rolling models e.g. the slab model to extend their deformation description regarding shear.

7.1 Superimposed shear

The shear angle \(\alpha\) represents a superimposed shear induced by the roll geometry and the frictional shear stress \({\tau }_{R}\). Section 5 implies that two separate shear values are required but the description of the shear based on a single value is sufficient. For integral rolling target values e.g. the equivalent strain, the path dependent description based on two shear angles are irrelevant due to the path independent nature of the target values. Even for the path dependent rolling target value, crystallographic texture, one superimposed shear value is sufficient. This is supported by the works of Lee and Duggan [42] and Engler et al. [105]. Both investigated the influence of the roll gap geometry and the frictional shear stress \({\tau }_{R}\) induced shear on the crystallographic texture. For this purpose, the shear induced by both mechanisms was varied with the condition that it equals to one superimposed shear value. They showed that different combinations of shear values create the same crystallographic texture as long they result into the same single shear value. Therefore, a description of the shear with a single shear angle \(\alpha\) is sufficient.

7.2 Determination of the shear angle \({\alpha }\) evolution

Figure 10 schematically presents the deformation path of the surface element to explain the method to determine the shear angle \(\alpha\). The example assumes an undeformed quadrilateral element for the purpose of simplification. The extension to different element shapes and deformed elements is easily achievable. The local Cartesian co-rotational coordinate system attached to the element schematically illustrates the element rotation experienced by the element. Section 8 presents later the determination of the element rotation. The element rotates through the entry into the roll gap and is aligned before and after the roll gap with the global coordinate system as long no unusual rolling events, such as alligatoring [130] occur.

Schematic presentation of the deformation path of the surface element part of the reference region along the rolling direction \({x}_{RD}\) simulated with FEM. A local Cartesian co-rotational coordinate system attached to the surface element schematically visualizes the element rotation. Gray dots emphasize the element nodal coordinates \(N\) only for the first element

To determine the shear angle \(\alpha\) evolution for the surface (Fig. 10), the element nodal coordinates \(N\) of the surface are extracted along the rolling direction \({x}_{RD}\). Afterwards, the shear angle \(\alpha\) depicted in Fig. 11 is determined for each rolling position \(x\) along the rolling direction \({x}_{RD}\) to get the shear angle \(\alpha\) evolution. A local Cartesian co-rotational coordinate system is applied to the element nodal coordinates \(N\) to obtain the shear angle \(\alpha\). This coordinate system is comparable with the local Cartesian co-rotational coordinate system described by Aukrust et al. [110] for the extrusion process. They set the co-rotational coordinate system based on the velocity on the streamline calculated by the FE simulation. Pérocheau and Driver [131] showed the application to FE rolling simulations. The intention of both works was the transformation of the deformation path obtained by the FE simulation with respect to the global coordinate system to a local coordinate system to obtain input values for a texture simulation. In this work, the local Cartesian co-rotational coordinate system is set based on the element nodal coordinates \(N\) to characterize the shear evolution. The procedure can be applied as post-processing to FE simulations without any modification, which represents an advantage. The rule to set the local Cartesian co-rotational coordinate system to determine the shear angle \(\alpha\) is described first visually and afterwards the mathematical method is given. Visually, the abscissa of the local Cartesian co-rotational coordinate system is aligned to the bottom edge of the element connected by the nodes \({N}_{1}\) and \({N}_{2}\). The origin of the local Cartesian co-rotational coordinate system is set on the node \({N}_{1}\). The angle between the ordinate of the local Cartesian co-rotational coordinate system and the element describes the shear, defined as shear angle \(\alpha\).

Element state for a rolling position \(x\) within the roll gap. The local Cartesian co-rotational coordinate system is aligned to the element to determine the shear angle \(\alpha\). The angle \(\beta\) represents the inner angle enclosed by the two vectors \({N}_{4}-{N}_{1}\) and \({N}_{2}-{N}_{1}\)

The shear angle \(\alpha\) can be directly determined mathematically by vector algebra according to Eq. 11 combined with Eq. 10, where \(b={N}_{4}-{N}_{1}\) and \(c={N}_{2}-{N}_{1}\).

Equation 10: Formula to calculate the inner angle \(\beta\) enclosed by two vectors. \(b\) and \(c\) are vectors, \(b\cdot c\) is the dot product and \(\left|b\right|\left|c\right|\) the multiplied vector lengths.

The 90° angle in Eq. 11 is attributed to the undeformed quadrilateral element assumption. The value needs to be adjusted, if a deformed element is considered.

Equation 11: Formula to calculate the shear angle \(\alpha\) combined with Eq. 10 for an initial undeformed quadrilateral element.

8 Description of the routine to calculate the deformation

This section presents a routine labeled CalculateHenckyStrain to calculate the deformation as Hencky strain. It is used as core part of the \(\alpha\)-\(h\)-Modell to calculate the deformation evolution. The routine based on the continuum mechanics calculates the deformation by means of the element nodal coordinates \(N\). It leans on equations presented in the Abaqus software manual [117] to determine deformation. By this way, the deformation calculated by the routine can be compared to the results of Abaqus Standard to validate the routine. This also enables the calculation of the deformation without the use of FEM. Only element nodal coordinates \(N\) are required, they can be generated by different methods like fast rolling models. As a result, a fast calculation of the deformation compared to FEM is achievable.

The flow chart in Fig. 12 schematically depicts the approach to calculate the deformation evolution as Hencky strain.

The procedure starts with the evolution of the element nodal coordinates \(N\) along the rolling direction \({x}_{RD}\) for the rolling stock position \(s\). The routine CalculateHenckyStrain calculates the deformation based on the element nodal coordinates \(N\) of the current- and reference configuration. In this case, \({N}_{ref}\) and \({N}_{cur}\) represent the element nodal coordinates \(N\) of the reference- and current configuration, respectively, like depicted in Fig. 4.

8.1 Calculation of the element deformation

The calculation methods mentioned in Sect. 4 are applied incrementally. The routine CalculateHenckyStrain determines for the deformation increment \(i\), the incremental element displacement \(\Delta {{\varvec{u}}}_{i}\) (Fig. 4) used to derive the incremental deformation gradient \(\Delta {{\varvec{F}}}_{i}\) (Eq. 1) for the element centroid. Afterwards by means of the polar decomposition, the incremental right stretch \(\Delta {{\varvec{U}}}_{i}\) and the incremental rotation \(\Delta {{\varvec{R}}}_{i}\) are calculated (Eq. 2). With the incremental right stretch \(\Delta {{\varvec{U}}}_{i}\), the incremental Hencky strain \(\Delta {{\varvec{E}}}_{i}^{H}\) is determined (Eq. 3).

8.2 Update the Hencky strain by applying the updated Lagrangian formulation

To accumulate the Hencky strain \({{\varvec{E}}}_{i}^{H}\) (Eq. 5) with the incremental Hencky strain \(\Delta {{\varvec{E}}}_{i}^{H}\), the rotation due to the deformation needs to be considered like described in Sect. 4.2.

8.3 Calculation of the material and the element rotation

A rigid-body rotation is applied to the element nodal coordinates \({N}_{ref}\) and \({N}_{cur}\).to determine both rotation components. Figure 13 exemplarily demonstrates the procedure for the element nodal coordinates \(N\). The angle \(\delta\) is determined to obtain the transformed element nodal coordinates \({N}^{\neg R}\). Visually, a local Cartesian coordinate system aligned with the global coordinate system is set with the origin on node \({N}_{1}\). Afterwards, the angle \(\delta\) between the \({x}_{CoR}\)-axis and the \({x}_{loc}\)-axis is determined. Mathematically, the angle \(\delta\) is calculated according to Eq. 10 with \(b={\left({x}_{2} 0\right)}^{T}\) and \(c={N}_{2}-{N}_{1}\).

Equation 12 defines the element rotation as \(R\left(\delta \right):=R(-\delta )\), if the node \({N}_{2}\) is below the \({x}_{loc}\)-axis, otherwise as \(R\left(\delta \right):=R(\delta )\).

Equation 12: Rotation matrix to transform the element nodal coordinates \(N\).

In the next step, Eq. 13 cancels the element rotation of the element nodal coordinates \(N\).

Equation 13: Formula to rotate the element nodal coordinates \(N\) to \({N}^{\neg R}\).

The presented procedure is applied to the element nodal coordinates \({N}_{{ref}}\) and \({N}_{{cur}}\) to determine the element nodal coordinates \({N}_{{ref}}^{\neg R}\) and \({N}_{{cur}}^{\neg R}\). The incremental element displacement \(\Delta {{\varvec{u}}}_{i}\) is calculated again for these modified element nodal coordinates to obtain the incremental material rotation \(\Delta {{\varvec{R}}}_{i}^{\mathrm{material}}\).

The outputs of the routine CalculateHenckyStrain are the accumulated Hencky strain \({{\varvec{E}}}^{H}\) and the accumulated rotation components along the rolling direction \({x}_{RD}\) for the rolling stock position \(s\).

9 Combination of the classical slab model with the shear angle \(\boldsymbol{\alpha }\) evolution

This section demonstrates the combination of the classical slab model and the shear angle \({\alpha }\) evolution. The shear angle \({\alpha }\) evolution is provided in the following by an \(\alpha\)-lookup-table as depicted in Fig. 14. This table can be constructed by an FE rolling study by extracting the sear angle \({\alpha }\) evolution, which is neglected in this paper for the sake simplicity.

It is known that the deformation evolution can be calculated based on the reference configuration and the current configuration [111]. The reference- and the current configuration represent, e.g., the element nodal coordinates \(N\) for the rolling positions \({x}_{i-1}\) and \({x}_{i}\), respectively. The current configuration is unknown and needs to be calculated. Figure 15 schematically presents the idea to achieve this.

Two displacement paths (\({\varvec{u}},{{\varvec{u}}}_{h}+{{\varvec{u}}}_{s})\) to reach the same current configuration for an undeformed quadrilateral element. On the Path: simultaneously, the element displacement \({\varvec{u}}\) applies simultaneously a height- \(h\) and a shear angle \(\alpha\) change. On the Path: sequentially, the element displacements \({{\varvec{u}}}_{h}\) and \({{\varvec{u}}}_{s}\) apply sequentially a height- \(h\) and a shear angle \(\alpha\) change, respectively

The current configuration in Fig. 15 (Path: simultaneously) can be directly reached by the element displacement \({\varvec{u}}\), which is unknown. But it is well-known that the element displacement \({\varvec{u}}\) can be decomposed in intermediate deformation increments [111]. Therefore, Fig. 15 (Path: sequentially) shows an alternative way to reach the current configuration by two increments. Through this, the same current configuration is reached via a temporary configuration. As a result, two models, one for the description of the shear angle \(\alpha\) change and another one for the description of the height \(h\) change can be used to take advantage of the circumstance shown in Fig. 15 (Path: sequentially). In this work, the classical slab model is used as an example to provide the height \(h\) change along the rolling direction \({x}_{RD}\) according to Eq. 14. The previously (Fig. 14) introduced \(\alpha\)-lookup-table provides the shear angle \(\alpha\) change.

Equation 14: Formula to calculate the height \(h\) evolution along the rolling direction \({x}_{RD}\) by the classical slab model [132].

Figure 16 schematically shows the combination of the classical slab model with the \(\alpha\)-lookup-table to construct the \(\alpha\)-\(h\)-Model. With this model, the calculation of the deformation path for rolling cases within the range of the hot FE rolling study is achievable. Based on the deformation path, each desired deformation value can be calculated. In this work, the deformation value is specified as Hencky strain. As a result, the shear evolution is presented as Hencky shear strain.

The \(\alpha\)-\(h\)-Model calculates the shape change of a virtual quadrilateral element based on the height \(h\) evolution and the shear angle \(\alpha\) evolution along the rolling direction \({x}_{RD}\) for a rolling stock position \(s\). Hereby, the element displacements \({{\varvec{u}}}_{h}\) and \({{\varvec{u}}}_{s}\) are calculated based on the height \({h}_{{x}_{i}}\) and shear angle \({\alpha }_{{x}_{i}}\) for the rolling position \({x}_{i}\). Both element displacements are applied to the reference configuration to determine the current configuration as shown in Fig. 15. The initial reference configuration is assumed as undeformed quadrilateral element for the sake of simplicity. The consideration of different initial configurations is possible. Furthermore, volume constancy is assumed as simplification. This neglects elastic deformation effects, which can be neglected for hot rolling due to the small ratio between elastic- and plastic deformation. The consideration of elastic effects is however possible with an extension [111]. For the next rolling position \({x}_{i+1}\), the current configuration is set as reference configuration and the procedure repeats. An evolution of element nodal coordinates \(N\) along the rolling direction \({x}_{RD}\) for the rolling stock position \(s\) is the result of the iteration. The routine CalculateHenckyStrain, presented in detail in Sect. 8, performs the calculation based on these element nodal coordinates \(N\). The output is the accumulated Hencky strain \({{\varvec{E}}}^{H}\) along the rolling direction \({x}_{RD}\) for the rolling position \(s\).

Due the focus of the work, the CalculateHenckyStrain routine provides only the accumulated Hencky strain \({{\varvec{E}}}^{H}\) as output. However, the deformation gradient \({\varvec{F}}\) calculated within the CalculateHenckyStrain routine represents the basis for each deformation formulation [111]. This allows the determination of any deformation values (strain, displacement- \({\varvec{H}}\) or velocity gradient \({\varvec{L}}\), etc.) with a small adjustment. Furthermore, the effort to change the formulation from the updated Lagrangian to the total Lagrangian is negligible. This enables the calculation of input values for fast texture models and also for slow texture models as the CPFEM [133].

10 FEM-reference to compare the \(\boldsymbol{\alpha }\)-\({\varvec{h}}\)-model

The \(\alpha\)-\(h\)-Model is element rotation-free due to the combination of the classical slab model and the \(\alpha\)-lookup-table. They both neglect the element rotation. Therefore, an element rotation-free reference is required to compare the shear strain evolution calculated by the \(\alpha\)-\(h\)-Model. This section constructs the FEM-reference, which fulfils the element rotation requirement based on Abaqus Standard.

The deformation path of the Abaqus Standard FE rolling model illustrated in Fig. 17a contains element rotation indicated by the local co-rotational Cartesian coordinate system. The element rotation can be canceled by use of the local co-rotational Cartesian coordinate system. Visually, the local co-rotational Cartesian coordinate system attached to the element is aligned with the global coordinate system to cancel the element rotation as depicted in Fig. 17b. The element rotation is canceled by a rigid-body rotation, which preserves the deformation state. This procedure can be applied to each element of the reference region. Through this, the deformation path calculated by the Abaqus Standard simulation can be transformed into a deformation path without element rotation, labeled FEM-reference. The transformed element nodal coordinates \(N\) of the FEM-reference can be used by the routine CalculateHenckyStrain to calculate the Hencky strain as described in Sect. 8. The shear strain evolution for this case is labeled with \({{shear}} E_{{{\neg ElmRot}}}^{H}\) to provide an easy distinction to \({{shear}} E^{H}\).

a Deformation path of the surface element part of the reference region simulated with Abaqus Standard. The local co-rotational Cartesian coordinate system attached to the element illustrates the element rotation. b The equivalent deformation path for the same surface element with canceled element rotation. The element nodal coordinates \(N\) are only highlighted for the rolling position \({x}_{i}\) with gray dots

Equation 15: Definition of the Hencky shear strain \({E}_{\neg ElmRot}^{H}\) calculated for the element nodal coordinates \(N\) with canceled element rotation.

10.1 Neglecting the material rotation

The deformation path contains element- and material rotation. They cause difficulties regarding interpretation and comparison of the shear strain evolution. This applies to \(shear {E}_{\neg {ElmRot}}^{H}\) calculated by the FEM-reference and to the shear strain evolution \({shear} {E}^{H}\) calculated by the \(\alpha\)-\(h\)-Model. Therefore, to be able to provide a meaningful interpretation, the material rotation must be neglected according to Eq. 16.

Equation 16: Formula to calculate the accumulated Hencky strain \({{\varvec{E}}}_{{i}_{\neg {Rot}}}^{H}\) for each deformation increment \(i\) with neglected rotation for the rolling stock position \(s\).

With this procedure, the calculation of the accumulated Hencky strain \({{\varvec{E}}}^{H}\) shown in Fig. 12 simplifies without the consideration of the material rotation for the element rotation-free case to a pure summation of the incremental Hencky strain \(\Delta {{\varvec{E}}}_{i}^{H}\). The shear strain evolution for this case labeled as \(shear {E}_{\neg {Rot}}^{H}\) is derived according to Eq. 17.

Equation 17: Definition of the Hencky shear strain \(shear {E}_{{i}_{\neg {Rot}}}^{H}\) for each deformation increment \(i\) based on the accumulated Hencky strain \({{\varvec{E}}}_{{i}_{\neg {Rot}}}^{H}(s)\) for the rolling position \(s\).

11 Results and discussion

The following section discusses the results regarding shear and rotation based on two rolling cases with different shear evolutions selected from the FE study. Table 1 shows the rolling parameters for the two investigated rolling cases.

The Coulomb friction coefficient \(\mu\) combined with the friction factor \(m\) is applied to the shear flow stress \(k\). Equation 8 determines the roll gap ratio \({l}_{c}/{h}_{m}\).

Figure 18 shows the results of the strain profile over the rolling stock height after the roll gap exit for both rolling cases.

The Abaqus strain (labeled in Abaqus Standard as PEEQ) profile is extracted from the Abaqus Standard simulation for the reference region after the roll gap exit. The mean Abaqus strain presents the arithmetic mean based on the extracted Abaqus strain profile. Black arrows mark the evaluation positions for each rolling case, individually chosen to investigate the specific effect on the shear. To clarify the importance of the shear consideration in general, the strain profile after the roll gap exit by the classical slab model is included

The total equivalent strain profiles after von Mises (black solid line) shown in Fig. 18 are already observed by several authors like Lachmann and Zouhar [102], Moon and Lee [134], Seuren et al. [84] and Serajzadeh [135]. The first rolling case with the small roll gap ratio \({l}_{c}/{h}_{m}\) shows a maximum total equivalent strain after von Mises below the surface. For this case, the three rolling stock positions \(s=0.95\), \(s=0.9\) and \(s=0.7\) are selected to investigate the effect of the shear evolution. The second rolling case with the large roll gap ratio \({l}_{c}/{h}_{m}\) leads to a monotonically increasing total equivalent strain after von Mises profile. Here, the three rolling stock positions \(s=0.9\), \(s=0.5\) and \(s=0\) are investigated.

Additionally, Fig. 18 demonstrates the importance of shear consideration in general by means of the classical slab model. Without any shear consideration, the classical slab model predicts the strain profile not well for both rolling cases. Furthermore, the total equivalent strain after von Mises by the classical slab model significantly deviates for both rolling cases compared to the mean Abaqus Standard. The deviation between them has the highest value of ~ 78% for the small roll gap ratio \({l}_{c}/{h}_{m}\) and a smaller one of ~ 24% for the large roll gap ratio \({l}_{c}/{h}_{m}\). As a result, even the determination of integral rolling target values with the classical slab model may be inaccurate.

The following evaluates the results for the marked rolling stock positions \(s\) (Fig. 18) covered by the topics given below.

-

Verification of the routine CalculateHenckyStrain shows the validity of the approach depicted in Fig. 12 to calculate the element deformation as Hencky strain based on the element nodal coordinates \(N\).

-

Shear angle \(\varvec{\alpha}\) evolution vs. Abaqus shear evolution compares both evolutions and discusses them.

-

FEM-reference shows the equivalence of the FEM-reference to Abaqus Standard with respect to deformation. The FEM-reference is used afterwards as reference to compare the shear strain evolution obtained by the α-\(h\)-Model.

-

Validation of the \(\varvec{\alpha}\)-\(\bf h\)-Model compares the shear strain evolution between the \({\alpha}\)-\(h\)-Model and the FEM-reference.

11.1 Verification of the routine CalculateHenckyStrain

Figure 19 schematically shows the procedure to validate the CalculateHenckyStrain routine.