Abstract

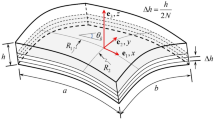

This paper presents the free vibration analysis of moderately thick and deep doubly curved laminated shell with \(C^{0}\) finite element model based on higher-order shear deformation theory. The strain–displacement relationships are developed using the accurate equations of elastic deformation of shell structure. An eight-noded isoparametric shell element with nine degrees of freedom per node is used to formulate the present model. The effect of incorporating the ratio of thickness coordinate to radius of curvature (z / R) in the strain components has been taken into account in the present study. The numerical results in terms of natural frequencies obtained by the present formulations are compared with those available in the published literature to validate the proposed model.

Similar content being viewed by others

References

Hildebrand, F.B., Reissner, E., Thomas, G.B.: Note on the foundations of the theory of small displacement of orthotropic shells. NACA TN 1833 (1949)

Nelson, R.B., Lorch, D.R.: A refined theory for laminated orthotropic plates. J. Appl. Mech. 41, 177–183 (1974). doi:10.1115/1.3423219

Whitney, J.M., Sun, C.T.: A higher order theory for extensional motion of laminated anisotropic shells and plates. J. Sound Vib. 30, 85–97 (1973). doi:10.1016/S0022-460X(73)80052-5

Levinson, M.: An accurate, simple theory of the statics and dynamics of elastic plates. Mech. Res. Commun. 7, 343–350 (1980). doi:10.1016/0093-6413(80)90049-X

Murthay, M.V.V.: An improved transverse shear deformation theory for laminated anisotropic plates. NASA technical paper 1903 (1981)

Lo, K.H., Christensen, R.M., Wu, E.M.V.: A higher order theory of plate deformation—Part I: Homogeneous plates. J. Appl. Mech. 44(4), 663–668 (1977). doi:10.1115/1.3424154

Lo, K.H., Christensen, R.M., Wu, E.M.V.: A higher order theory of plate deformation—Part II: Homogeneous plates. J. Appl. Mech. 44(4), 669–676 (1977). doi:10.1115/1.3424155

Reddy, J.N., Liu, C.F.: A higher-order shear deformation theory of laminated elastic shells. Int. J. Eng. Sci. 23, 319–330 (1985). doi:10.1016/0020-225(85)90051-5

Reddy, J.N.: A simple higher order theory for laminated composite plate. J. Appl. Mech. 51(4), 745–752 (1984). doi:10.1115/1.3167719

Mantari, J.L., Oktem, A.S., Guedes Soares, C.: Static and dynamic analysis of laminated composite and sandwich plates and shells by using a new higher order shear deformation theory. Compos. Struct. 94, 37–49 (2011). doi:10.1016/j.compstruct.2011.07.020

Kant, T., Menon, M.P.: Higher order theories for composite and sandwich cylindrical shells with \(\text{ C }^{\rm 0 }\) finite element. Comput. Struct. 33(5), 1191–1204 (1989). doi:10.1016/0045-7949(89)90458-6

Qatu, M.S.: Accurate equations for laminated composite deep thick shells. Int. J. Solids Struct. 36, 2917–2941 (1999). doi:10.1016/s0020-7683(98)00134-6

Qatu, M.S.: Theory and vibration analysis of laminated barrel thick shells. J. Vib. Control 10, 319–341 (2004). doi:10.1016/s0020-7683(98)00134-6

Ganapathi, M., Haboussi, M.: Free vibrations of thick laminated anisotropic non-circular cylindrical shells. Comput. Struct. 60, 125–133 (2003). doi:10.1016/s0263-8223(02)00339-2

Bhimaraddi, A.: Free vibration analysis of doubly curved shallow shells on rectangular planform using three-dimensional elasticity theory. Int. J. Solids Struct. 27(7), 897–913 (1991). doi:10.1016/0020-7683(91)90023-9

Carrera, E.: The effect of shear deformation and curvature on buckling and vibrations of cross-ply laminated composite shells. J. Sound Vib. 150(3), 405–433 (1991). doi:10.1016/0022-460X(91)90895-Q

Thakur, S.N., Ray, C.: An accurate \({\rm C}^{0}\) finite element model of moderately thick and deep laminated doubly curved shell considering cross sectional warping. Thin Wall Struct. 94, 384–393 (2015). doi:10.1016/j.tws.2015.04.027

Hosseini-Hashemi, S.H., Atashipour, S.R., Fadaee, M., Girhammar, U.A.: An exact closed-form procedure for free vibration analysis of laminated spherical shell panels based on Sanders theory. Arch. Appl. Mech. 82, 985–1002 (2012). doi:10.1007/s00419-011-0606-0

Civalek, O.: Vibration analysis of laminated composite conical shells by the method of discrete singular convolution based on the shear deformation theory. Compos. Part B Eng. 45, 1001–1009 (2013). doi:10.1016/j.compositesb.2012.05.018

Ye, T., Jin, G., Zhu, Su, Jia, X.Z.: A unified Chebyshev–Ritz formulation for vibration analysis of composite laminated deep open shells with arbitrary boundary conditions. Arch. Appl. Mech. 84, 441–471 (2014). doi:10.1007/s00419-013-0810-1

Civalek, O.: Geometrically nonlinear dynamic analysis of doubly curved isotropic shells resting on elastic foundation by a combination of HDQ-FD methods. Int. J. Press. Vessels Pip. 82, 470–479 (2005). doi:10.1016/j.ijpvp.2004.12.003

Author information

Authors and Affiliations

Corresponding author

Appendices

Appendix 1

Rigidity matrix of laminates using model 1:

where the values of above matrix coefficients are given by

and

where \(i, j= 1, 2, 4, 5, 6\) and \(C_0 =\left( {\frac{1}{R_{s} }-\frac{1}{R_{r} }} \right) \).

Appendix 2

Rigidity matrix of laminates using model 2:

where the values of above matrix coefficients are given by

where \(i, j= 1, 2, 4, 5, 6\).

Rights and permissions

About this article

Cite this article

Thakur, S.N., Ray, C. The effect of thickness coordinate to radius ratio on free vibration of moderately thick and deep doubly curved cross-ply laminated shell. Arch Appl Mech 86, 1119–1132 (2016). https://doi.org/10.1007/s00419-015-1082-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00419-015-1082-8