Abstract

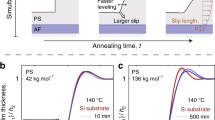

Effects of surface topology and energy on the stick-slip transition were studied in capillary flow of highly entangled polyethylene (PE) melts. Surface roughness was shown to increase the critical stress of the stick-slip transition because of the increased resistance to interfacial disentanglement. Lowering the surface energy of a smooth die wall by treatment with a fluorocarbon completely eliminates the stick-slip transition and produces massive interfacial slip at PE/wall boundary down to a stress level of 0.05 MPa. On the other hand, considerable roughness on the same low energy surface can produce a stick hydrodynamic boundary condition and restore the stick-slip transition despite the weak PE/wall interfacial interactions. Additionally, a slip-slip transition was found in the die with a nearly non-adsorbing wall that appears to involve a secondary chain-debonding process.

Similar content being viewed by others

References

Bagley EB, Cabot IM, West DC (1958) Discontinuity in the flow curve of polyethylene. J Appl Phys 29:109–110

Bergem N (1976) Visualization studies of polymer melt low anomalies in extrusion. Proc 7th Internal Congr Rheol. Swedish Society of Rheology, p 50

Blyler LL Jr, Hart AC Jr (1970) Capillary flow instability of ethylene polymer melts. Polym Eng Sci 10:193–203

Brochard F, de Gennes PG (1992) Sheardependent slippage at a polymer/solid interface. Langmuir 8:3033–3037

El Kissi N, Leger L, Piau JM, Mezghani A (1994) Effect of surface properties on polymer melt slip and extrusion defects. J Non-Newt Fluid Mech 52:249–261

Hatzikiriakos SG, Dealy JM (1991) Wall slip of molten high density polyethylene. I. Sliding plate rheometer studies. J Rheol 35:497–523

Hatzikiriakos SG, Dealy JM (1992) Role of slip and fracture in the oscillating flow of HDPE in a capillary. J Rheol 36:845–884 and references therein

Inn YW, Wang SQ (1996) Hydrodynamic slip: polymer adsorption and desorption at melt/solid interfaces. Phys Rev Lett 79:467–470

Kalika DS, Denn MM (1987) Wall slip and extrudate distortion in linear low-density polyethylene. J Rheol 31:815–834

Knappe W Krumböck E (1984) Evaluation of slip flow of PVC-compounds by capillary rheometry. In: Mena B, Garcia-Rejon A, Range] Nafaile C (eds) Advances in Rheology (Proc. IX Intl. Congr. Rheol.), vol 3, p 417

Larson RG (1992) Instabilities in viscoelastic flow. Rheol Acta 31:213–263 and references therein

Metzger AP, Hamilton CW (1964) The oscillating shear phenomenon in high density polyethylenes. SEP Trans 4:107–112

Migler KB, Hervet H, Leger L (1993) Slip transition of a polymer melt under shear stress. Phys Rev Lett 70:287–290

Petrie CJS, Denn MM (1976) Instabilities in polymer processing. AIChE J 22:209–236 and references therein; Denn MM (1990) Issues in viscoelastic fluid mechanics. Ann Rev Fluid Mech 22:13–34 and references therein since 1976; Denn MM (1992) Surface-induced effects in polymer melt flow. In: Moldenaers P, Keunigs R (eds) Theoretical and Applied Rheology (Proc. XIth Int. Congress on Rheology) vol 1, Elsevier, pp 45-49

Rudin A, Chang RJ (1978) A study of melt density of flowing linear polyethylene. J Appl Polym Sci 22:781–799

Tordella JP (1963) Unstable flow of molten polymers: a second site of melt fracture. J Appl Polym Sci 7:215–229; Tordella JP (1969) Unstable flow of molten polymers Rheology, Vol 5. Eirich FR (ed) Academic Press, pp 57–91

Waddon A, Keller A (1990) A temperature window of extrudability and reduced flow resistance in high-molecular-weigth polyethylene — interpretation in terms of flowinduced mobile hexagonal phase. J Polym Sci B 28:1063–1073

Wang SQ, Drda PA (1996a) Superfluid-like stick-slip transition in capillary flow of linear polyethylene melts. I. General features. Macromolecules 29:2627–2632

Wang SQ, Drda PA (1996b) Stick-slip transition in capillary flow of polyethylene. 2. Molecular weight dependence and lowtemperature anomaly. Macromolecules 29:4115–4119

Wang SQ, Drda PA, Inn YW (1996c) Exploring molecular origins of sharkshin, partial slip and slope change in flow curves of linear low density polyethylene. J Rheol 40:875–898

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, SQ., Drda, P.A. Stick-slip transition in capillary flow of linear polyethylene: 3. Surface conditions. Rheola Acta 36, 128–134 (1997). https://doi.org/10.1007/BF00366818

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF00366818