Abstract

The hydrodynamics of thin films is an important factor when it comes to the stability and rheology of multiphasic materials, such as foams, emulsions, and polymer blends. However, there have so far been only limited experimental studies addressing the dynamics of individual free-standing thin films at conditions similar to those encountered on macroscopic scales. In this article, we study a well-characterized system of a water-in-oil emulsion stabilized by a non-ionic surfactant (SPAN80) close to its CMC. We employ a dynamic thin film balance, to study the dynamics of freestanding films under both constant and time-varied pressure drops. We compare with the recently published results of Narayan et al. (2020) on colliding droplets of the same system with a hydrodynamic microfluidic trap, and show for the first time that agreement between the two lengthscales is possible, which indicates that the coalescence is indeed dominated by the dynamics in the film. We then address the scatter in the coalescence times and show that it can be affected by extrinsic factors, as well as by variations in the collision angle. Finally, we discuss the difficulties of extracting insight on the coalescence mechanism from coalescence time distributions when different effects such as impurities, small pressure variations, collision angle variations, and possible Marangoni-related instabilities are at play.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Multi-phase soft materials, such as foams, emulsions, and immiscible polymer blends, are important in many aspects of everyday life (Schramm 2006; Paul and Barlow 1980). In these materials, the structure, stability, and macroscopic rheology are controlled by processes that occur at the film (microscale) and droplet/bubble level (mesoscale) (Macosko 2000; Mason 1999; Tadros 2013; Vermant et al. 2004; Grizzuti and Bifulco 1997; Otsubo and Prud’homme 1994; Niedzwiedz et al. 2010). For example, the rheological properties of interfaces at the air/water interface are known to affect both drainage and Ostwald ripening (Saint-Jalmes 2006; Beltramo et al. 2017; Georgieva et al. 2009), which in turn influence the average bubble size, and thus the so-called yield stress, of the macroscopic foam (Princen and Kiss 1989; Kraynik and Hansen 1987). Nevertheless, comparison of the same system at different lengthscales (micro- and mesoscale) remains difficult (Rio and Biance 2014; Narayan et al. 2020; Monin et al. 2000; Braun et al. 2020) and has so far been reported mainly at a qualitative level. Therefore, it is still unclear if experimental techniques with access to different lengthscales probe the same macroscopic properties. In particular, it is unclear if the idealized conditions of thin film drainage realized in a free-standing but quiescent film mimic the conditions in coalescence experiments, where the droplets interact and complicated disturbance velocity fields are present.

The simplest parameter describing the stability of emulsions and foams is the coalescence time, i.e., the time needed for two droplets/bubbles to merge into one. This process, which is controlled by the dynamics of the liquid film that separates the two droplets (Chan et al. 2011), is typically characterized by a certain degree of randomness. Thus, the droplet coalescence time (\(t_c\)) and the film rupture times (\(t_r\)) are commonly reported in the form of distributions, which in certain cases may even span over several orders of magnitude (Suja et al. 2018, 2020; Lhuissier and Villermaux 2012; Chatzigiannakis and Vermant 2020; Narayan et al. 2020; Giribabu and Ghosh 2007; Charles and Mason 1960; Exerowa et al. 1983; Mazutis and Griffiths 2012; Dinh et al. 2021; Tian et al. 2022; Frostad et al. 2016). Several parameters can affect the width of \(t_c\) and \(t_r\), namely surfactant impurities (Stubenrauch and Khristov 2005), dust (Vitry et al. 2019; de Gennes 2001), surface concentration fluctuations and the (not very likely for most surfactants (de Gennes 2001)) possibility of hole nucleation (Exerowa et al. 1983; Langevin 2020; Casteletto et al. 2003), dissolved gasses (Dudek et al. 2018; Nguyen et al. 2010), and spontaneously growing thickness fluctuations (Vrij 1966; Chatzigiannakis and Vermant 2020; Aarts et al. 2004).

Moreover, when it comes to systems stabilized by surfactants, the “stochastic” nature of coalescence is partially related to the sensitivity of the Marangoni stresses to the experimental conditions which can have a huge effect on the drainage behavior of the film separating the two droplets (Suja et al. 2018; Joye et al. 1994).

In the present work, we use a modified dynamic version of the thin film balance (DTFB) (Chatzigiannakis et al. 2020) to study the dynamics of emulsion (water-in-oil) films stabilized by a non-ionic surfactant. The traditional versions of the thin film balance usually study films at equilibrium, or quasi-static conditions, and often in a well-protected environment, conditions that are too ideal when compared to other experiments involving droplets or even emulsions (Chatzigiannakis et al. 2021; Suja et al. 2020). Thus, film properties do not always correlate well with the macroscopic properties of the material (Braun et al. 2020; Monin et al. 2000). In the present work, we study how pressure variations and the presence of extrinsic factors like impurities affect the dynamics and lifetimes of the freestanding films. We compare with the existing results of Narayan et al. (2020) who studied the same system with the hydrodynamic microfluidic trap (HMT) technique, which involves the collision of droplets in extensional flow. Having access to both the micro- and the meso-scale, we gain significant insight regarding the mechanisms that affect the width of coalescence time distributions.

Theoretical background

Droplet coalescence and film drainage of surfactant-stabilized systems have been extensively studied in the past both experimentally and numerically (Chan et al. 2011). The most important dimensionless groups that describe the process are described in brief below.

First, the capillary number Ca describes the interplay between hydrodynamics and capillarity. Following previous studies, we define a macroscopic (\(Ca_m\)) and a microscopic — or film — capillary number (\(Ca_f\)), which are closely related. The macroscopic capillary number is defined as (Leal 2004):

where \(\eta _c\) is the viscosity of the continuous (oil) phase, \(\gamma\) is the equilibrium interfacial tension, R is the radius of the droplet (or of the bike-wheel’s hole in the DTFB measurements), and \(U_m\) is the approaching droplet velocity before it comes in contact with the trapped droplet in the HMT experiments.

Chan et al. (2009) showed using the Stokes-Reynolds-Young-Laplace framework that the deformation of the film, and thus its thinning, is controlled by the film Capillary number:

where the Capillary number for the film is now scaled with the characteristic thickness of the film, H, and the radius R. The film’s characteristic dimensions used here are the radius and height of the bike-wheel hole, 0.5 mm and 200 \(\mu\)m, respectively. The characteristic velocity \(U_f\) used here is assumed to scale with the experimentally measured film expansion rate, \(\upsilon _r\), evaluated at the initial stages of drainage (SI and Chatzigiannakis and Vermant (2021)). Thus, with Eqs. 1 and 2, a comparison between techniques that probe different lengthscales is possible if the characteristic velocities are either a priori known (e.g., in flow-controlled collisions as investigated in the HMT) or a posteriori measured (as in the pressure-controlled DTFB experiments).

Beyond Ca, three other key dimensionless groups for surfactant-stabilized films and droplets are:

-

The Marangoni number, which describes the competition between Marangoni and viscous stresses. This ratio provides information about the magnitude of interfacial stresses that oppose liquid outflow from the film (Manikantan and Squires 2020; Pourali 2021):

$$\begin{aligned} Ma = \frac{ K_{\Pi }}{\eta _c \upsilon _r } , \end{aligned}$$(3)where \(K_{\Pi }\) is the Gibbs-Marangoni modulus.

-

The Péclet number, which describes the type of surfactant transport (convection versus diffusion) (Manikantan and Squires 2020; Hermans et al. 2015):

$$\begin{aligned} Pe_s = \frac{R \upsilon _r}{D_s} , \end{aligned}$$(4)where \(D_s\) is the surface diffusion coefficient. Both bulk and surface diffusion can contribute to the attenuation of Marangoni stresses, depending not only on the properties of the two phases, but also on the thickness of the film (Ivanov 1980). However, as the \(D_s\) is very difficult to determine experimentally, we report here only the \(Pe= R \upsilon _r /D\) where D is the bulk diffusion coefficient. For most surfactants, \(D_s\) is one to two orders of magnitude smaller than D (Langevin 1998).

-

The dimensionless disjoining pressure, which describes the relative magnitude of intermolecular forces with respect to the viscous ones (Chatzigiannakis et al. 2021):

$$\begin{aligned} \Pi ^*_{d}=\frac{\Pi _d}{\Delta P} , \end{aligned}$$(5)where \(\Pi _d\) is the total disjoining pressure that acts across the films’ interfaces according to the DLVO theory (Israelachvili 2015) (see SI for the calculated \(\Pi _d\) of the studied system) and \(\Delta P\) is the total pressure that drives film drainage. If no external pressure is applied to the film then \(\Delta P\) is equal to the capillary pressure exerted by the curvature of the bike-wheel’s hole (or equivalently of the droplet) (\(2\gamma /R\)).

The overall film dynamics are connected by an interplay between the effects described above, i.e., capillarity, hydrodynamics, interfacial stresses, surfactant transport, and intermolecular forces (Chatzigiannakis et al. 2021). For interfaces stabilized by low molecular weight surfactants, the effect of interfacial viscosity, and thus of the Boussinesq number, is estimated to be negligible (Zell et al. 2014).

Materials and methods

Materials

Three different concentrations of SPAN80 (Sigma-Aldrich — S6760, \(d=0.99~g/ml\), \(M_w=428.6~g/mol\)) of 0.005, 0.05, and 0.1 v/v% were dissolved in a light mineral oil (Sigma-Aldrich — M3516, \(d=0.838~g/ml\)). SPAN80 is a non-ionic surfactant that predominantly consists of sorbitan mono- and dioleate, together with various other lower molecular weight subfractions (Abou-Nemeh and Bart 1998). Deionized water (Millipore Milli-Q system, resistivity 18.2 M\(\Omega\)cm) was used for the outer “droplet” phase.

The main properties of these systems have already been extensively studied by Narayan et al. (2020). The viscosity of the light mineral oil is \(26.8~mPa\cdot s\) and the equilibrium interfacial tensions of the 0.005, 0.05, and 0.1 v/v% SPAN80 solutions are approximately 10, 6, and 6 mN/m, respectively (Narayan et al. 2020). Both degassed and as-received mineral oil/surfactant solutions were studied. Degassing was conducted in a desiccator under vacuum for 20 min.

Methods

Thin film drainage measurements were conducted with a dynamic version of the bike-wheel microfluidic thin film balance (DTFB) (Pereira et al. 2001; Chatzigiannakis et al. 2020) which is based on the original technique of Sheludko (1967). Details about the experimental technique and its manufacture can be found elsewhere (Beltramo et al. 2016). Head-on collisions between droplets were mimicked by applying a constant positive pressure step \(\Delta P\) on top of the pressure that corresponds to the mechanical equilibrium of the film using the experimental procedure described in Chatzigiannakis and Vermant (2020) with the minor changes described below.

As the refractive indices of water (\(n_{water}=1.333\)) and the mineral oil (\(n_{water}=1.467\)) are close, the determination of the exact pressure for the mechanical equilibrium is difficult to determine. Therefore, for the comparison with the flow-controlled experiments of Narayan et al. (2020), we a posteriori determined the characteristic velocity after applying a pressure step when the initial conditions were expected to be close to a mechanical equilibrium. Thus, the \(Ca_f\) numbers vary somewhat between films.

However, this procedure could not be followed to compare with pressure-controlled experiments as done in the “Thin film dynamics at a constant driving pressure” section. For this set of measurements, extra care was taken to accurately determine the initial point of mechanical equilibrium and only two separate pressure steps \(\Delta P\) were applied. The process of forming and equilibrating the film takes approximately 5 min, which for similar systems appears comparable to the time needed to reach the equilibrium interfacial tension in the concentration range that we studied (Santini et al. 2007).

Glancing collisions, i.e., collisions at a non-zero collision angle, were studied applying a sinusoidal pressure profile, following the work of Borrell et al. (2004). The magnitude of the collision angle offset was controlled by the period (T) of the cosinusoidal pressure profile:

The cosinusoidal pressure profile was applied starting from a film in mechanical equilibrium. Thus, the pressure exerted on the film corresponds to a sudden step in pressure, which then gradually decreases with time. In experiments involving droplets, the magnitude of the equivalent \(\Delta P\) will depend both on the employed flow rate and the size of the droplets (Borrell et al. 2004). We followed the time evolution of the force reported by Borrell et al. (2004), who defined the onset of the drainage time (\(t=0\)) when the force has its maximum value. However, there are cases where the actual force takes some time to develop (Frostad et al. 2016; Kannan et al. 2018). Therefore, our experimental procedure corresponds to an idealized case, which represents a film between two droplets of the same size which collide at different collision angles but under the same flow-rates assuming the drainage process is the rate determining step. To mimic even more realistic collisions between droplets, one would ideally have to obtain the driving force or pressure from simulations and then apply it to a thick free-standing film.

In the DTFB experiments, the drainage time \(t_d\) is defined by the interval between the onset of film expansion and film rupture (Chatzigiannakis and Vermant 2020). The onset of film expansion occurs when the hydrodynamic pressure inside the film is comparable to the Laplace pressure (Chesters 1991). When comparing to droplets, in the Ca range that we examined, the \(t=0\) corresponds to a film thickness of \(O(1)~\mu m\). In the HMT experiments, Narayan et al. (2020) defined the drainage time as the time interval during which the change in the center-to-center distance of the two colliding droplets is observed to be constant, as the resolution of the employed microscope would not capture submicrometer changes in the film thickness during film drainage.

Following the definition of Chesters (1991) and the experimental procedure described above, the coalescence time (\(t_c\)), drainage time (\(t_d\)), and the time needed for film rupture (\(t_r\)) are almost equal for the system we studied, with any differences being in the order of milliseconds.

Results and discussion

Coalescence and drainage times: comparison between techniques

The dimensionless drainage time is plotted as a function of the relevant Ca number in Fig. 1. The agreement between the two techniques for low capillary numbers is remarkable. The small differences, e.g., in scatter for the largest Ca numbers, will be discussed later in the text, but are related to the presence of impurities and/or small variations in the collision angle of the two droplets in the HMT (“Quantifying scatter in coalescence time” section). The scaling of \(t_d \sim Ca^{-1}\) , expected for pressure-driven flow for planar films (Chatzigiannakis and Vermant 2020), is shown as a dotted line for reference. When comparing the evolution of the drainage time with Ca to the microscopic observations in the DTFB, we can now gain some insight regarding the mechanisms that are at play in droplet coalescence from the dynamics of the film at the microscale.

Scaled drainage times (HMT and DFTB) for different concentrations of SPAN80 as a function of the macroscopic and film capillary numbers, respectively. Filled symbols correspond to the DTFB results and open symbols to the published results of the macroscopic hydrodynamic microfluidic trap (Narayan et al., 2020; 2022)

First, in the range of applied Ca, the films rupture without or just after the formation of a dark domain. When the dark domains are observed (e.g., Fig. 2g), they did not have time to expand and had a thickness comparable to a Newton black film (NBF) (\(\sim\) 10 nm). Thus, the effect of the repulsive disjoining pressure because of steric interactions between opposing surfactant molecules is negligible in the studied range of concentration, in agreement with the previous results of Politova et al. (2017a).

The effect of the applied Ca on the overall morphology of the films is shown in Fig. 2 and in Movies S1–S6. The interferometric images show how the film changes from slightly dimpled (with a darker, thicker region in the center) to overly deformed (with a much larger — yet unstable — dimple) as the \(Ca_f\) number increases. At high \(Ca_f\) numbers, the flow in certain films became unstable, with various Marangoni-related instabilities, such as thickness corrugations and vortices being observed (Joye et al. 1994; Kannan et al. 2018; Karakashev et al. 2010). The magnitude of these flow instabilities got more pronounced with increasing SPAN80 concentration.

Thin film dynamics at a constant driving pressure

All the TLFs were thermodynamically unstable and ruptured without the formation of a NBF, regardless of surfactant concentration and applied Ca. Therefore, the total film lifetime and the respective coalescence time of the droplets is dominated by drainage, as assumed in Narayan et al. (2020) and in agreement to the earlier results of Politova et al. (2017a).

The detailed microscopy observations show that for very small Ca numbers, the films remain planar and thin, while the radius is constant in a regime where hydrodynamics are dominant. Therefore, at low Ca, even quasi-static drainage approaches, such as the Reynolds equation and its modified versions, are applicable (Chatzigiannakis et al. 2021). For higher Ca numbers, such simplistic approximations will fail and more rigorous numerical simulations are needed as the film becomes dimpled (Chan et al. 2011). The thinning velocity V in this simplified case, based on a generalized drainage equation, is given by Sheludko (1967); Ivanov (1980)

where h is the film’s thickness, \(R_f\) is the film’s radius, and f is a mobility factor which describes deviations from the Poiseuille flow inside the film (for which \(f=1\)). Equation 7 was solved numerically in Matlab with the Runge-Kutta method using the calculated disjoining pressure (SI) and the average experimental film radius.

The experimental drainage curve (h vs. t) of a film with 0.05 v/v% SPAN80 for \(\Delta P = 0.2~\)Pa corresponding to a very low \(Ca_f\) number. The predictions of the Reynolds equation (Eq. 7) and for a film thinning by the viscous stresses of the outer phase (water) (Yang et al. 2001) are also shown for comparison. The red shaded area corresponds to deviations in the Reynolds prediction expected due to the small differences in the applied \(\Delta P\) (SI). Comparison is done after the film radius reaches its equilibrium value at \(t_i\)

The theoretical prediction of Eq. 7 for \(f=1\) is shown in Fig. 3 together with the experimentally measured thickness at the center of the film for \(\Delta P = 0.2~\)Pa (determined from a pressure balance for the experimental \(R_f\) (Toshev and Ivanov 1975)). Good agreement, within experimental error, is observed for \(f=1\), which is an indication that the interfaces are highly stress-carrying due to Marangoni stresses. In our experiments, the Ma and Pe (Eqs. 3 and 4) are \(\gg 1\), high enough to lead to the development of Marangoni stresses.

The highly stress-carrying nature of the interfaces and the agreement with Eq. 7 is in contrast to the results of Politova et al. (2017a) who reported faster drainage compared to the Reynolds prediction for water-in-dodecane emulsion films stabilized by SPAN80 at concentrations close to CMC. However, this observation could also be related to the fact that they did not consider the subtle but important effect of attractive van der Waals contribution to the drainage rate.

In any case, the magnitude of interfacial stresses depends on Pe and \(Pe_s\) (Chatzigiannakis et al. 2021; Dai and Leal 2008) and might change with increasing Ca (Frostad et al. 2016), as observed for SPAN80-stabilized emulsion droplets (Politova et al. 2017b). Nevertheless, the quasi-static drainage of films stabilized by non-ionic surfactants usually shows an agreement with the Reynolds prediction and is rather insensitive to concentration, as long as this remains close to CMC (Karakashev et al. 2010). Similarly, in our results (Fig. 1), the drainage time does not depend significantly on the concentration of SPAN80 (in the studied range).

Another contribution to the total interfacial stress in emulsion films comes from the viscous contributions generated in the outer phase (water). This effect can be described by the pre-factor in the drainage equation of Yang et al. (2001) for which \(f=1+R_f/(\lambda h), \lambda\) being the viscosity ratio between the outer and the inner phase. The predicted drainage curve if bulk viscous stresses are the dominant contribution to interfacial stresses is shown with the blue solid line in Fig. 3. Despite the approximate nature of the equation proposed by Yang et al. (2001), it shows that bulk viscous stresses have only a small contribution to the total interfacial stresses as the viscosity of the liquid in the film (light mineral oil) is significantly larger than that of the outer phase (water).

Despite the good agreement between the two techniques, there is a notable difference. The scatter in the coalescence times determined by the macroscopic HMT is much larger compared to that of the DTFB. Moreover, the coalescence times of the lowest SPAN80 concentration showed rather low drainage times and a weak dependence on the Ca number, which is in clear contrast to the DTFB results. In the next subsection, we will investigate the reasons behind this behavior. We will show how the strong Marangoni stresses discussed earlier can significantly influence the dynamics of the films during a glancing collision or its mimic in a DTFB.

Quantifying scatter in coalescence time

Although coalescence times and film lifetimes are typically reported with large standard deviations, as distributions, or as scattered single data points (Frostad et al. 2016; Dudek et al. 2020; Mazutis and Griffiths 2012; Suja et al. 2018; Chatzigiannakis and Vermant 2020; Dinh et al. 2021; Exerowa et al. 1983; Suja et al. 2020; Saulnier et al. 2014; Narayan et al. 2020; Miguet et al. 2021; Poulain et al. 2018; Vitry et al. 2019; Tian et al. 2022), the origin of this scatter is rarely addressed, mostly because of the difficulties that such a practice entails (i.e., decoupling the scatter due to experimental control, extrinsic factors such as impurities, and intrinsic ones such as thermocapillary waves and surface concentration fluctuations). Here, we will investigate two of the main contributions to the scatter, namely that of extrinsic factors like impurities and variations in the collision angle. The latter are specifically important in microfluidic experiments which cannot precisely control the collision angle, whereas in DTFB the temporal control of the pressure profile is absolute.

a Films stabilized by 0.005 v/v% SPAN80 just before rupture for \(Ca_f = 1.2 \cdot 10^{-4}\) number. Left: degassed oil. Right: non-degassed oil. b The dimensionless drainage time as a function of \(Ca_f\) for a degassed and non-degassed 0.005 v/v% SPAN80 solution. The already published coalescence times from Narayan et al. (2020) are shown for comparison

Extrinsic factors causing premature film rupture

The coalescence time has been found to strongly depend on various external factors, such as dissolved gases, microbubbles, impurities in the surfactant or oil, and dust (Charles and Mason 1960; MacKay and Mason 1963; Burrill and Woods 1973; Hodgson and Lee 1969; De Malmazet et al. 2015; de Gennes 2001; Stubenrauch and Khristov 2005; Schlarmann et al. 2003; Bergeron and Radke 1992; Karakashev and Nguyen 2009). All these factors lead to premature rupture and to the widening of the distribution of coalescence times (Vitry et al. 2019; De Malmazet et al. 2015), which in extreme cases can result in a coalescence time that is effectively independent of droplet size or Ca number (De Malmazet et al. 2015). Here, we will term these factors as extrinsic to differentiate them from effects intrinsic to surfactant-stabilized films, such as surface concentration fluctuations, hole nucleation (Exerowa et al. 1983), and thermocapillary waves (Vrij 1966).

The oil and the surfactant used in our study are not pure substances but mixtures of various components, some of which are expected to be volatile and of low Mw (Urlaub et al. 2019; Grob et al. 1991; Abou-Nemeh and Bart 1998). Moreover, SPAN80 has been found to interact strongly with components in other commercially available mineral oils (Botti et al. 2022).

To assess the possible effect of the multi-component nature of the studied systems on film lifetime distributions, we examined both degassed and not-degassed light mineral oil solutions. Degassing has been found to significantly improve the stability of oil films between water droplets (Maeda et al. 2004; Pashley 2003; Karakashev and Nguyen 2009) and, although the actual mechanism by which it works is not clear (Eastoe and Ellis 2007), degassing is expected to remove volatile impurities, dissolved gases, and bubbles formed by unintentional agitation.

Interestingly, when non-degassed mineral oil was used, several dark spots were observed in the films prior to rupture (Fig. 4a and Movie S7a). These dark spots caused the premature rupture of films, similar to antifoam agents (Denkov et al. 2014). They are probably related to components either of the mineral oil or of SPAN80, both of which are multicomponent mixtures of substances (Abou-Nemeh and Bart 1998), although the presence of microbubbles or dissolved gas cannot be excluded (Nguyen et al. 2010; Dudek et al. 2018).

Although the degree of acceleration in the coalescence time will depend on many factors such as the concentration, type, and relative size of the impurities (Vitry et al. 2019; Stubenrauch and Von Klitzing 2003), it is evident from Fig. 4b that their inclusion in the film results in premature rupture and in an increased scatter in the measured coalescence times. We believe that this could be a possible reason for the flattening of the coalescence times of the 0.005 v/v% solutions in the HMT. The low concentration and poorer stabilizing effect of SPAN80 could be related to the higher sensitivity of the films to extrinsic factors causing rupture.

The premature rupture of one of the films (of 0.05 v/v% in this case) was caused by a satellite oil droplet (Movie S7b). Although rare, such events might also contribute to smaller values of \(t_c\) in the DTFB.

Regardless of the actual cause of the premature rupture of certain films, by directly visualizing the film, we can simply observe if extrinsic effects, which facilitate coalescence, are present. Extrinsic factors will act on top of intrinsic ones and should be carefully accounted for when the rupture of surfactant-stabilized films is discussed and examined.

Effect of collision angle

Although microfluidic studies can be a high-throughput method to study coalescence of emulsions (Chatzigiannakis et al. 2021; Ho et al. 2022), most setups offer a rather poor control with respect to the collision angle (Narayan et al. 2020; Krebs et al. 2012; Dudek et al. 2020; Mazutis and Griffiths 2012; Tian et al. 2022; Zhang et al. 2020). However, the collision angle has been shown to affect significantly the coalescence time (Yang et al. 2001). Despite the fact that in most applications involving flowing emulsions the probability of a head-on collision is close to zero (Leal 2004), the dynamics of films under conditions that correspond to non-zero collision angles have not yet been studied systematically.

In glancing conditions under the elongation-dominated flow in the HMT, the force, and thus also the pressure that drives drainage, varies cosinusoidally with time (Borrell et al. 2004). Using a piezoelectric pressure control system, we applied a quarter period of a cosinusoidal pressure profile on the 0.05 v/v% emulsion films. By changing the period of the wave while keeping constant the initial (or maximum) \(\Delta P\), we were able to investigate how films behave under conditions similar to those experienced in glancing collisions. The applied pressure profiles are shown in Fig. 5. In the case of the “head-on collisions”, the pressure that drives drainage is kept constant. Thus, the film will always rupture as long as \(\Pi ^*_d \le 1\) (Eq. 5). In contrast, in the experiments which mimic glancing collisions, \(\Delta P\) first decreases cosinusoidally with time. Film rupture occurs only if the period T is large enough for a given \(\Delta P\). This is equivalent to the offset angle and Ca being within a certain range (Leal 2004)). In the present experiments, this transition was found to occur roughly at \(T=180~\)s. By employing different T (Fig. 5), we can assess how \(t_c\) varies in an experiment in which the collision angle is only roughly controlled (as is the case with most microfluidic methods). Roughly, a \(10^o\) deviation in the collision angle can, depending on the Ca number, result in a rotation of \(50-70^o\) before coalescence occurs (Narayan et al. 2020) which can have a significant effect on the coalescence time (Yang et al. 2001).

Similarly to the period T, we define an offset pressure \(\Delta P_{offset}\) which corresponds to the ratio between the average pressure during the first 60 s (dotted line in Fig. 5) and the initial \(\Delta P\). A higher \(\Delta P_{offset}\) corresponds to a lower T and thus to stronger deviations from an ideal head-on collision. Although the choice of 60 s is arbitrary, the use of \(\Delta P_{offset}\) allows us to roughly compare with other pressure-controlled experiments.

Two characteristic data sets are shown in Fig. 6. Movies of films draining under a time-dependent \(\Delta P\) can be found in the SI (Movies S8–S10). When the collision occurs head-on (Fig. 6a), the pressure that drives drainage is constant. Therefore, the film expands and thins continuously. Film expansion will stop when the equilibrium radius is reached, as dictated by a pressure balance in the Plateau border (Toshev and Ivanov 1975). In contrast, in glancing collisions, the pressure decreases with time (Fig. 6b). Therefore, the radius of the film varies non-monotonically with time. The film initially thins and expands until it reaches the equilibrium \(R_f\) for a given \(\Delta P (t)\). From this point on, the continuous decrease in \(\Delta P\) results in thickening of the film and its retraction. The film typically exhibits a protrusion near the edge, which in certain cases can be so pronounced that locally the minimum thickness is reached and rupture occurs (Bremond et al. 2008; Chatzigiannakis et al. 2020). Therefore, in glancing collisions, the drainage time depends non-trivially on the time-evolving \(\Delta P\), \(R_f\), and h. Moreover, for the systems under investigation, the magnitude and the sign of Marangoni stresses are expected to depend non-trivially upon the inversion of flow (Yoon et al. 2007b).

In Fig. 7a, we plot the experimentally measured film radius \(R_f\) as a function of time for a head-on collision and three glancing collisions using different contact periods. For clarity, only two characteristic measurements are shown for each set of experiments (more measurements can be found in the SI). Film rupture coincides with the last data point recorded. As explained above, the film initially expands and then starts retracting (equivalent to the retraction or separation regime in droplet collisions). The change in the two regimes is shown with arrows in Fig. 7a.

In the thin film balance experiments, regardless of the magnitude of \(\Delta P\) or T, the onset of film retraction was always accompanied by the dimple becoming unstable and getting washed out towards the rim of the film. Thickness corrugations in the film were then observed. Such effects have been extensively reported in literature and are caused by Marangoni stresses (Chandran Suja et al. 2021; Joye et al. 1994; Yaminsky et al. 2010; Karakashev et al. 2010; Bhamla et al. 2017). This behavior is in clear contrast with the axisymmetric drainage assumption typically employed in theory and numerical simulations (Dai and Leal 2008; Janssen et al. 2006; Chan et al. 2011; Leal 2004). The non-axisymmetric drainage in the droplet separation phase could be the reason behind the poor agreement between the experimental results of Narayan et al. (2020) and the theoretical predictions of Leal and coworkers (Yang et al. 2001).

a The evolution of film radius as a function of time for four pressure profiles for the same initial \(Ca_f\) (0.05 v/v%). The change from “approach” to “retraction” for each set of measurements is shown with the respective arrow. b The average drainage time with increasing standard deviations from the “head-on” collision case (which corresponds to \(\Delta P_{offset} = 0\)) (0.05 v/v%) to \(\Delta P_{offset} = 0.4\)

For systems for which the interfacial boundary conditions are controlled only by the viscous ratio between the outer and the inner phase and a constant interfacial tension, the standard deviation of the coalescence time is not expected to be affected by the collision angle (Yang et al. 2001; Vakarelski et al. 2010). However, this was not the case in the experiments reported in our study. In Fig. 7b, we plot the drainage time as a function of the offset pressure as defined earlier. At least 5 measurements have been done for each T at the same initial \(\Delta P\). The standard deviation of the film drainage time increases as the mimicked collision becomes more glancing, i.e., as T decreases.

We believe that this increase in the standard deviation is related to the combined effect of strong Marangoni stresses (as discussed in section “Thin film dynamics at a constant driving pressure”) that cause the recirculation of liquid together with impurities (as discussed in the “Extrinsic factors causing premature film rupture” section. The variation in the collision angle (or equivalently in T) results in a variation in the onset of film retraction. The latter stage of the collision started with the dimple becoming unstable causing a chaotic Marangoni flow. Apart from imparting randomness in the drainage velocity of the films, when accompanied by impurities (some of which remain present in the continuous phase after degassing, albeit at much lower concentrations), Marangoni flow and recirculation can also affect the probability of such an impurity to be present or flow back in the film region and thus cause premature rupture (Lhuissier and Villermaux 2012; Joshi et al. 2009). As a result, the distribution of coalescence time is observed to increase a lot. We note that the dependence of the \(t_c\) on the interrelated effect of Marangoni stresses and impurities occurs on top of stochastic events typically attributed to surfactants (e.g., the possibility of hole nucleation (Langevin 2020)).

Coalescence time distributions

Having studied two of the main effects that are expected to affect the measured coalescence times when studied at realistic conditions (impurities and variations in the collision angle), we can now assess the effects that are at play in previous experimental studies, but all investigating the same system, i.e., water-in-oil emulsion films or droplets stabilized by SPAN80 close to the CMC.

Coalescence time distributions can be conveniently fitted by the Weibull cumulative distribution function (CDF) (Suja et al. 2020; Chatzigiannakis and Vermant 2020; Vitry et al. 2019), which has also been widely used to describe the fracture of solids (Lu et al. 2002; Hallinan 1993):

where \(t_m\) is the scale parameter, which is similar to the mean coalescence time (Hallinan 1993), and b is the shape factor, which is indicative of the shape and broadness of the distribution.

In addition, b provides some insight regarding the time-dependence of the underlying rupture mechanism. For \(b>1\), the probability for rupture or coalescence increases with time. A large b is expected for deterministic rupture (i.e., the Weibull converges to a degenerate distribution or to a Heaviside function) (Vitry et al. 2019; Chatzigiannakis and Vermant 2020). On the other end, a simple exponential distribution, approximated by \(b=1\), is expected for systems where a purely stochastic mechanism such as thermal or mechanical fluctuations (Chatzigiannakis and Vermant 2020) or hole nucleation is the dominant rupture mechanism (Casteletto et al. 2003; Stubenrauch et al. 2005; Langevin 2020). As shown by Lhuissier and Villermaux (2012) and discussed by Miguet et al. (2021), a \(b=4/3\) is expected for systems containing impurities in presence of Marangoni recirculation (or to be specific marginal regeneration in their case). Finally, the \(b\simeq 3.6\) corresponds to a symmetric distribution, which so far has been observed for films at finite Ca numbers with simple interfaces whose rupture is controlled by the evolution of spontaneously growing thickness fluctuations (Chatzigiannakis and Vermant 2020).

In the following, we discuss two important parameters that characterize the distribution of coalescence time of the SPAN80-stabilized emulsions films, namely the average coalescence time, \(t_c\) and the width and shape of the distribution, as described by b. We will compare our results with literature reports on similar systems. This comparison allows us to evaluate the pitfalls that should be avoided when interpreting coalescence time distributions.

Average coalescence time, \(t_c\)

The average coalescence time is the main parameter that is used to describe the coalescence of two colliding droplets. As discussed in the previous subsection, the measured coalescence times are not only controlled by the phenomena and instabilities mentioned above, but also on the time needed for the film to drain down to a thickness typically of \(\sim O(10)\) nm. This competition of time-scales (a drainage-dominated one and one related to an instability causing rupture) has already been discussed in numerous studies (Rio and Biance 2014; Chatzigiannakis and Vermant 2020; Stubenrauch et al. 2005; Frostad et al. 2016).

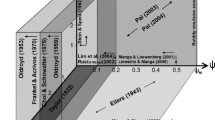

In the system we studied, as well as in other studies using SPAN80 dissolved in oil or an organic solvent, the drainage time is usually \(O(10-10^2)\) s and it should thus be much larger than the characteristic time-scale of rupture. To confirm that at the studied range of SPAN80 concentration the rate-determining step in coalescence is the hydrodynamic drainage time, we conducted many experiments at the same applied \(\Delta P\) (instead of a posteriori calculating the \(Ca_f\) as done in Fig. 1). The obtained reduced drainage time \(t_dh_c^2/(\eta _c R_f^2)\) is plotted as a function of the total pressure \(\Delta P\) that drives film drainage in Fig. 8a together with other pressure-controlled experimental studies on similar SPAN80-stabilized systems (Dinh et al. 2021; Politova et al. 2017a; Narayan et al. 2020; Giribabu and Ghosh 2007).

The Reynolds equation (Eq. 7) is applicable for small but finite \(\Delta P\) (or Ca) and thus we show only results from measurements conducted in this regime. A critical thickness of 12 nm was used for all films, as determined by Politova et al. (2017a). Figure 8a shows that the reduced drainage time is inversely proportional to the total pressure drop, exactly as expected from the Reynolds equation (Eq. 7). This is a clear indication that drainage dominates the coalescence time in the studied SPAN80 concentration range. This argument is further supported by visual observations of the draining films rupturing just after the nucleation of a dark domain, both by us as well as by Politova et al. (2017a).

As discussed earlier, film rupture can be either intrinsic when instabilities such as hole nucleation (Exerowa et al. 1983) or fluctuations (Vrij 1966) occur, or extrinsic. In the former case, the characteristic timescale of rupture is controlled by the time needed for the instability to evolve. Similarly, in the extrinsic rupture of films, de Gennes proposed that there is a characteristic rupture time related to the diffusion of the particle inside the film (de Gennes 2001).

The linear dependence observed for the scaled drainage time with \(\Delta P\) in Fig. 8a means that the actual timescale for rupture, either extrinsic or intrinsic, is masked by the dominant hydrodynamic drainage time. Therefore, even if a phenomenon intrinsic to surfactants, such as hole nucleation, is present and causes rupture, it cannot be detected through the \(t_c\) at the surfactant concentration range of 0.1–8 CMC, in strong contrast to what Dinh et al. (2021) claim. “Turning off” hydrodynamics is impossible, at least in this concentration range of SPAN80, with the drainage keep playing a dominating role even when the Ca numbers are small, but finite.

a The drainage time reduced by the capillary time scale as a function of \(\Delta P\) for various studies (Dinh et al. 2021; Politova et al. 2017a; Narayan et al. 2020; Giribabu and Ghosh 2007). The theoretical prediction of Eq. 7 is shown with a dotted line. b The shape factors of Weibull distribution of the drainage time distributions the present experiments plotted together with literature results (Dinh et al. 2021; Politova et al. 2017a; Narayan et al. 2020; Giribabu and Ghosh 2007) as a function of \(\Delta P\). For Narayan et al. (2020), the shape factor was determined for 0.01 v/v% SPAN80 in light mineral oil for \(Ca_m=4.9 \cdot 10^{-4} \pm 1.5\cdot 10^{-5}\). The predictions of \(b=1\) (Casteletto et al. 2003), \(b=4/3\) (Lhuissier and Villermaux 2012), \(b=2\) (Suja et al. 2018), and of \(b=3.6\) (Chatzigiannakis and Vermant 2020) are shown with different horizontal lines. The error bars correspond to the fitting error. The fitted solid black line is a guide to the eye

Shape of the distribution of \(t_c\)

The second characteristic of the CDF of the coalescence time is the width and shape of the distribution, which is described by the shape factor b (Eq. 8). Apart from improving the modelling of processes involving droplet coalescence, understanding what controls the shape of the distribution could potentially allow us to solve the inverse problem, i.e., understudying the fundamental physics involved in coalescence from the CDF of \(t_c\), as for example attempted in Dinh et al. (2021) and Casteletto et al. (2003).

The shape factor of various experimental studies employing SPAN80-stabilized emulsion droplets or films is shown in Fig. 8a as a function of the total driving pressure \(\Delta P\) in each experiment. Some details on the experimental method and procedure used in each study are shown in Table 1. The data were extracted from the respective graphs and then fitted with the OriginTM-built-in Levenberg-Marquardt algorithm. In Fig. 8b, we show how the distributions of coalescence times at similar \(\Delta P\) can have completely different shape factors because of the effects discussed so far (thinning velocity, Marangoni instabilities, variation in the collision angle, and dust).

First, Fig. 8 shows how b (and hence the distribution of \(t_c\)) increases with \(\Delta P\). Within an order of magnitude change in \(\Delta P\), the shape factor ranges from a value close to 1 (stochastic) to \(b \ge 10\), corresponding to an at least apparently deterministic distribution. At low \(\Delta P\), all experimental results show a distribution close to the prediction of \(b=4/3\).

Together with the results of literature, we plot the shape factors determined in our film drainage experiments for the mimicked head-on collisions (constant \(\Delta P\)) and the different glancing collisions (various time-dependent \(\Delta P\)). For the “head-on collisions”, increasing the driving pressure results in a more deterministic rupture as indicated by the larger shape factor. This is in agreement with previous results on simple polymer solution films in absence of extra interfacial stresses (Chatzigiannakis and Vermant 2020). It is probably related to the fact that for the studied concentration range of SPAN80 it is \(\Pi ^*_d \ll 1\). The large fitting error in the case of the “head-on collisions” at high \(\Delta P\) is related to the inability of the Weibull CDF to properly fit the \(t_c\) that have the form of a degenerate distribution (Vitry et al. 2019).

Keeping \(\Delta P\) constant and then gradually decreasing it, as would be expected to take place in a glancing collision, results to the widening of the distributions and thus to a lower value of b. Moreover, decreasing T and thus deviating more from the ideal head-on collision results in further reducing the shape factor. Similarly, droplet collision studies at which the angle cannot be precisely controlled (Narayan et al. 2020; Giribabu and Ghosh 2007) show rather low shape factors between 4/3 and 3.

However, variations in the collision angle are not the only factor that can lower b. Applying a similar \(\Delta P\) to the films of the non-degassed oil results in a b almost equal to that of the glancing collisions, in agreement to previous results (Lhuissier and Villermaux 2012). In these measurements, the shape factor we obtained includes also some variations in \(\Delta P\) (due to the pressure fluctuations or small differences in the equilibrium pressure), which is difficult to decouple.

Apart from these extrinsic effects that influence b, there are also intrinsic ones, such as hole nucleation. In this case, a \(b=1\) is theoretically expected (Casteletto et al. 2003). However, from the discussion made above, it is clear that when it comes to droplet coalescence and film rupture there are several effects that superimpose, thus making very difficult — if not impossible — the extraction of reasonable conclusions about the exact rupture mechanism from merely the shape of the distribution.

Moreover, the shape factor expected for surfactant-stabilized films rupturing intrinsically (\(b=1\)) is very close to the value expected for surfactant films rupturing extrinsically (\(b=4/3\)). Therefore, acquiring information about the rupture mechanism from the shape of the distribution of \(t_c\) should at least involve highly purified surfactants and a large number of measurements, while simultaneously studying the films in a regime where hydrodynamics are negligible (e.g., high surfactant concentrations which allow the formation of Newton black films).

In conclusion, the shape of the \(t_c\) distributions depends on the experimental conditions (and setup). Therefore, if the conditions mentioned above cannot be met, the shape of the distribution should be used only for obtaining rough qualitative insight on the underlying mechanisms, as was for example done by Frostad et al. (2016).

Nevertheless, combined, Fig. 8a and b can be used to solve the inverse problem of correlating the obtained b to the respective rupture mechanism after excluding hydrodynamics and could be considered as a standard way to look at data coming out of future studies. Although deducing mechanistic insight from \(t_c\) distributions and the fitted shape factor is difficult, it is clear that the more idealized DTFB studies executed at realistic Ca numbers while simultaneously allowing film visualization can prove useful in addressing long-lasting questions related to multiphase soft materials like foams and emulsions, such as the exact rupture mechanism of surfactant-stabilized films.

The next step would be to include the third relevant lengthscale of the macroscopic system, correlating processes that take place at the film and the bubble/droplet level to the rheology and stability of emulsions and foams.

Conclusions

The drainage of SPAN80-stabilized oil films in water was studied using the dynamic thin film balance method. For a constant applied \(\Delta P\) — which mimics a perfect head on collision — the film drainage time was in very good agreement with the literature values of Narayan et al. (2020) which were obtained by studying the collisions of droplets of the exact same system with the hydrodynamic microfluidic trap technique. The influence of impurities and variation of collision angle — unavoidably present in droplet-droplet collision experiments — on the distribution of drainage or coalescence times was also evaluated. Impurities are suggested to decrease film lifetime and increase scatter, with the distribution of \(t_c\) being in qualitative agreement with the theory of Lhuissier and Villermaux (2012).

Glancing collisions of droplets under varied collision angles were mimicked by using a quarter period of a cosinusoidal pressure profile to the films and changing the duration of the cosine. Drainage under such time-varied \(\Delta P\) took place asymmetrically with the evolution of many Marangoni-related instabilities. The resulting chaotic flow together with the presence of a small but non-negligible amount of impurities resulted in significant variations in the measured \(t_c\) and in distributions similar to those obtained for films with a much larger amount of impurities present. Decoupling multiple drainage and rupture-related effects from the distribution of coalescence times alone remains difficult given that impurities and collision angle variations affect the shape of the \(t_c\) distribution to the same extent as the stochastic aspects of the underlying mechanisms. Moreover, in the case of SPAN80 at concentrations close to CMC, it was shown that the hydrodynamic drainage time dominates the lifetime of the film. Thus, rupture-related processes, either due to surfactant concentration fluctuations (or hole nucleation) or simply due to impurities or fluctuations, cannot be discerned or uniquely identified with confidence if fast enough visualization of the film is not possible.

However, given the excellent agreement observed between the microscopic film lengthscale studied with the DTFB and the mesoscopic droplet lengthscale studied with the HMT, we can engineer DTFB experiments to imitate the more “realistic” conditions involved in droplet collision studies and possibly answer some long-lasting questions regarding the properties of surfactant-stabilized films. Finally, this work hence paves the way towards understanding how the dynamics at the microscopic film level affect the bulk rheology of multiphasic soft materials. This will in turn facilitate the optimization of surface active species to achieve enhanced rheological properties and will allow improved predictions of the structure of such materials under flow.

References

Aarts DG, Schmidt M, Lekkerkerker HN (2004) Direct visual observation of thermal capillary waves. Science 304(5672):847–850

Abou-Nemeh I, Bart H (1998) Microstructures in the system water/D2EHPA/Span-80/n-dodecane. Langmuir 14(16):4451–4459

Beltramo PJ, Van Hooghten R, Vermant J (2016) Millimeter-area, free standing, phospholipid bilayers. Soft Matter 12(19):4324–4331

Beltramo PJ, Gupta M, Alicke A, Liascukiene I, Gunes DZ, Baroud CN, Vermant J (2017) Arresting dissolution by interfacial rheology design. Proceedings of the National Academy of Sciences 114(39):10373–10378

Bergeron V, Radke C (1992) Equilibrium measurements of oscillatory disjoining pressures in aqueous foam films. Langmuir 8(12):3020–3026

Bhamla MS, Chai C, Alvarez-Valenzuela MA, Tajuelo J, Fuller GG (2017) Interfacial mechanisms for stability of surfactant-laden films. PloS ONE 12(5):e0175753

Borrell M, Yoon Y, Leal LG (2004) Experimental analysis of the coalescence process via head-on collisions in a time-dependent flow. Phys Fluids 16(11):3945–3954

Botti TC, Hutin A, Quintella E, Carvalho M (2022) Effect of interfacial rheology on drop coalescence in water-oil emulsion. Soft Matter 18(7):1423–1434

Braun L, Kühnhammer M, von Klitzing R (2020) Stability of aqueous foam films and foams containing polymers: discrepancies between different length scales. Curr Opin Colloid Interface Sci 50:101379

Bremond N, Thiam AR, Bibette J (2008) Decompressing emulsion droplets favors coalescence. Phys Rev Lett 100(2):024501

Burrill K, Woods D (1973) Film shapes for deformable drops at liquid-liquid interfaces. II. The mechanisms of film drainage. J Colloid Interface Sci 42(1):15–34

Casteletto V, Cantat I, Sarker D, Bausch R, Bonn D, Meunier J (2003) Stability of soap films: hysteresis and nucleation of black films. Phys Rev Lett 90(4):048302

Chan DY, Klaseboer E, Manica R (2009) Dynamic deformations and forces in soft matter. Soft Matter 5(15):2858–2861

Chan DY, Klaseboer E, Manica R (2011) Film drainage and coalescence between deformable drops and bubbles. Soft Matter 7(6):2235–2264

Chandran Suja V, Hadidi A, Kannan A, Fuller G (2021) Axisymmetry breaking, chaos, and symmetry recovery in bubble film thickness profiles due to evaporation-induced Marangoni flows. Phys Fluids 33(1):012112

Charles GE, Mason SG (1960) The coalescence of liquid drops with flat liquid/liquid interfaces. J Colloid Sci 15(3):236–267

Chatzigiannakis E, Vermant J (2020) Breakup of thin liquid films: from stochastic to deterministic. Phys Rev Lett 125(15):158001

Chatzigiannakis E, Veenstra P, Ten Bosch D, Vermant J (2020) Mimicking coalescence using a pressure-controlled dynamic thin film balance. Soft Matter 16(41):9410–9422

Chatzigiannakis E, Jaensson N, Vermant J (2021) Thin liquid films: where hydrodynamics, capillarity, surface stresses and intermolecular forces meet. Curr Opin Colloid Interface Sci 53:101441

Chatzigiannakis E, Vermant J (2021) Dynamic stabilisation during the drainage of thin film polymer solutions. Soft Matter 17(18):4790–4803

Chesters A (1991) Modelling of coalescence processes in fluid-liquid dispersions: a review of current understanding. Chem Eng Res Des 69(A4):259–270

Dai B, Leal LG (2008) The mechanism of surfactant effects on drop coalescence. Phys Fluids 20(4):040802

de Gennes P-G (2001) Some remarks on coalescence in emulsions or foams. Chem Eng Sci 56(19):5449–5450

De Malmazet E, Risso F, Masbernat O, Pauchard V (2015) Coalescence of contaminated water drops at an oil/water interface: influence of micro-particles. Colloids Surf A Physicochem Eng Asp 482:514–528

Denkov ND, Marinova KG, Tcholakova SS (2014) Mechanistic understanding of the modes of action of foam control agents. Adv Colloid Interface Sci 206:57–67

Dinh H-H-Q, Santanach-Carreras E, Lalanne-Aulet M, Schmitt V, Panizza P, Lequeux F (2021) Effect of a surfactant mixture on coalescence occurring in concentrated emulsions: the hole nucleation theory revisited. Langmuir 37(29):8726–8737

Dudek M, Muijlwijk K, Schroën K, Øye G (2018) The effect of dissolved gas on coalescence of oil drops studied with microfluidics. J Colloid Interface Sci 528:166–173

Dudek M, Fernandes D, Herø EH, Øye G (2020) Microfluidic method for determining drop-drop coalescence and contact times in flow. Colloids Surf A Physicochem Eng Asp 586:124265

Eastoe J, Ellis C (2007) De-gassed water and surfactant-free emulsions: history, controversy, and possible applications. Adv Colloid Interface Sci 134:89–95

Exerowa D, Balinov B, Kashchiev D (1983) Nucleation mechanism of rupture of newtonian black films: II. Experiment. J Colloid Interface Sci 94(1):45–53

Frostad JM, Paul A, Leal LG (2016) Coalescence of droplets due to a constant force interaction in a quiescent viscous fluid. Phys Rev Fluids 1(3):033904

Frostad JM, Tammaro D, Santollani L, de Araujo SB, Fuller GG (2016) Dynamic fluid-film interferometry as a predictor of bulk foam properties. Soft Matter 12(46):9266–9279

Georgieva D, Cagna A, Langevin D (2009) Link between surface elasticity and foam stability. Soft Matter 5(10):2063–2071

Giribabu K, Ghosh P (2007) Adsorption of nonionic surfactants at fluid-fluid interfaces: importance in the coalescence of bubbles and drops. Chem Eng Sci 62(11):3057–3067

Grizzuti N, Bifulco O (1997) Effects of coalescence and breakup on the steady-state morphology of an immiscible polymer blend in shear flow. Rheol Acta 36(4):406–415

Grob K, Biedermann M, Caramaschi A, Pacciarelli B (1991) LC-GC analysis of the aromatics in a mineral oil fraction: batching oil for jute bags. J High Resolut Chromatogr 14(1):33–39

Hallinan AJ Jr (1993) A review of the weibull distribution. J Qual Technol 25(2):85–93

Hermans E, Bhamla MS, Kao P, Fuller GG, Vermant J (2015) Lung surfactants and different contributions to thin film stability. Soft matter 11(41):8048–8057

Ho TM, Razzaghi A, Ramachandran A, Mikkonen KS (2022) Emulsion characterization via microfluidic devices: a review on interfacial tension and stability to coalescence. Adv Colloid Interface Sci 299:102541

Hodgson T, Lee J (1969) The effect of surfactants on the coalescence of a drop at an interface I. J Colloid Interface Sci 30(1):94–108

Israelachvili JN (2015) Intermolecular and surface forces. Academic Press, New York, pp 326–327

Ivanov IB (1980) Effect of surface mobility on the dynamic behavior of thin liquid films. Pure Appl Chem 52(5):1241–1262

Janssen P, Anderson P, Peters G, Meijer H (2006) Axisymmetric boundary integral simulations of film drainage between two viscous drops. J Fluid Mech 567:65–90

Joshi K, Baumann A, Jeelani S, Blickenstorfer C, Naegeli I, Windhab EJ (2009) Mechanism of bubble coalescence induced by surfactant covered antifoam particles. J Colloid Interface Sci 339(2):446–453

Joye J-L, Hirasaki GJ, Miller CA (1994) Asymmetric drainage in foam films. Langmuir 10(9):3174–3179

Kannan A, Shieh IC, Leiske DL, Fuller GG (2018) Monoclonal antibody interfaces: dilatation mechanics and bubble coalescence. Langmuir 34(2):630–638

Karakashev SI, Nguyen AV (2009) Do liquid films rupture due to the so-called hydrophobic force or migration of dissolved gases? Langmuir 25(6):3363–3368

Karakashev SI, Ivanova DS, Angarska ZK, Manev ED, Tsekov R, Radoev B, Slavchov R, Nguyen AV (2010) Comparative validation of the analytical models for the marangoni effect on foam film drainage. Colloids Surf A Physicochem Eng Asp 365(1–3):122–136

Kraynik AM, Hansen MG (1987) Foam rheology: a model of viscous phenomena. J Rheol 31(2):175–205

Krebs T, Schroën K, Boom R (2012) Coalescence dynamics of surfactant-stabilized emulsions studied with microfluidics. Soft Matter 8(41):10650–10657

Langevin D (1998) Dynamics of surfactant layers. Curr Opin Colloid Interface Sci 3(6):600–607

Langevin D (2020) On the rupture of thin films made from aqueous surfactant solutions. Adv Colloid Interface Sci 275:102075

Leal L (2004) Flow induced coalescence of drops in a viscous fluid. Phys Fluids 16(6):1833–1851

Lhuissier H, Villermaux E (2012) Bursting bubble aerosols. J Fluid Mech 696:5–44

Lu C, Danzer R, Fischer FD (2002) Fracture statistics of brittle materials: Weibull or normal distribution. Phys Rev E 65(6):067102

MacKay GDM, Mason SG (1963) The gravity approach and coalescence of fluid drops at liquid interfaces. Can J Chem Eng 41(5):203–212

Macosko CW (2000) Morphology development and control in immiscible polymer blends. In: Macromolecular Symposia, vol. 149. Wiley Online Library, pp 171–184

Maeda N, Rosenberg KJ, Israelachvili JN, Pashley RM (2004) Further studies on the effect of degassing on the dispersion and stability of surfactant-free emulsions. Langmuir 20(8):3129–3137

Manikantan H, Squires TM (2020) Surfactant dynamics: hidden variables controlling fluid flows. J Fluid Mech 892

Mason T (1999) New fundamental concepts in emulsion rheology. Curr Opin Colloid Interface Sci 4(3):231–238

Mazutis L, Griffiths AD (2012) Selective droplet coalescence using microfluidic systems. Lab on a Chip 12(10):1800–1806

Miguet J, Rouyer F, Rio E (2021) The life of a surface bubble. Molecules 26(5):1317

Monin D, Espert A, Colin A (2000) A new analysis of foam coalescence: from isolated films to three-dimensional foams. Langmuir 16(8):3873–3883

Narayan S, Makhnenko I, Moravec DB, Hauser BG, Dallas AJ, Dutcher CS (2020) Insights into the microscale coalescence behavior of surfactant-stabilized droplets using a microfluidic hydrodynamic trap. Langmuir 36(33):9827–9842

Narayan S, Metaxas AE, Bachnak R, Neumiller T, Dutcher CS (2020) Zooming in on the role of surfactants in droplet coalescence at the macroscale and microscale. Curr Opin Colloid Interface Sci 50:101385

Narayan S, Makhnenko I, Moravec DB, Hauser BG, Dallas AJ, Dutcher CS (2022) Correction to “insights into the microscale coalescence behavior of surfactant-stabilized droplets using a microfluidic hydrodynamic trap’’. Langmuir 38(8):2749–2750

Nguyen PT, Nguyen AV (2010) Drainage, rupture, and lifetime of deionized water films: effect of dissolved gases? Langmuir 26(5):3356–3363

Niedzwiedz K, Buggisch H, Willenbacher N (2010) Extensional rheology of concentrated emulsions as probed by capillary breakup elongational rheometry (CaBER). Rheol Acta 49(11):1103–1116

Otsubo Y, Prud’homme RK (1994) Effect of drop size distribution on the flow behavior of oil-in-water emulsions. Rheol Acta 33(4):303–306

Pashley R (2003) Effect of degassing on the formation and stability of surfactant-free emulsions and fine Teflon dispersions. J Phys Chem B 107(7):1714–1720

Paul D, Barlow J (1980) Polymer blends. J Macromol Sci Polymer Rev 18(1):109–168

Pereira LGC, Johansson C, Blanch HW, Radke CJ (2001) A bike-wheel microcell for measurement of thin-film forces. Colloids Surf A Physicochem Eng Asp 186(1–2):103–111

Politova N, Tcholakova S, Denkov ND (2017) Factors affecting the stability of water-oil-water emulsion films. Colloids Surf A Physicochem Eng Asp 522:608–620

Politova NI, Tcholakova S, Tsibranska S, Denkov ND, Muelheims K (2017) Coalescence stability of water-in-oil drops: effects of drop size and surfactant concentration. Colloids Surf A Physicochem Eng Asp 531:32–39

Poulain S, Villermaux E, Bourouiba L (2018) Ageing and burst of surface bubbles. J Fluid Mech 851:636–671

Pourali M, Kröger M, Vermant J, Anderson PD, Jaensson NO (2021) Drag on a spherical particle at the air-liquid interface: interplay between compressibility, Marangoni flow, and surface viscosities. Phys Fluids 33(6):062103

Princen H, Kiss A (1989) Rheology of foams and highly concentrated emulsions: IV. An experimental study of the shear viscosity and yield stress of concentrated emulsions. J Colloid Interface Sci 128(1):176–187

Rio E, Biance A-L (2014) Thermodynamic and mechanical timescales involved in foam film rupture and liquid foam coalescence. ChemPhysChem 15(17):3692–3707

Saint-Jalmes A (2006) Physical chemistry in foam drainage and coarsening. Soft Matter 2(10):836–849

Santini E, Liggieri L, Sacca L, Clausse D, Ravera F (2007) Interfacial rheology of Span 80 adsorbed layers at paraffin oil-water interface and correlation with the corresponding emulsion properties. Colloids Surf A Physicochem Eng Asp 309(1–3):270–279

Saulnier L, Champougny L, Bastien G, Restagno F, Langevin D, Rio E (2014) A study of generation and rupture of soap films. Soft Matter 10(16):2899–2906

Schlarmann J, Stubenrauch C, Strey R (2003) Correlation between film properties and the purity of surfactants. Phys Chem Chem Phys 5(1):184–191

Schramm LL (2006) Emulsions, foams, and suspensions: fundamentals and applications. John Wiley & Sons, New York

Sheludko A (1967) Thin liquid films. Adv Colloid Interface Sci 1(4):391–464

Stubenrauch C, Khristov K (2005) Foams and foam films stabilized by cntab: influence of the chain length and of impurities. J Colloid Interface Sci 286(2):710–718

Stubenrauch C, Von Klitzing R (2003) Disjoining pressure in thin liquid foam and emulsion films—new concepts and perspectives. J Phys Condens Matter 15(27):R1197

Stubenrauch C, Langevin D, Exerowa D (2005) Comment on “stability of soap films: Hysteresis and nucleation of black films.” Phys Rev Lett 95(8):088901

Suja VC, Kar A, Cates W, Remmert SM, Savage PD, Fuller GG (2018) Evaporation-induced foam stabilization in lubricating oils. Proceedings of the National Academy of Sciences 115(31):7919–7924

Suja VC, Rodríguez-Hakim M, Tajuelo J, Fuller GG (2020) Single bubble and drop techniques for characterizing foams and emulsions. Adv Colloid Interface Sci 286:102295

Tadros TF (2013) Emulsion formation and stability. John Wiley & Sons, New York

Tian YS, Li EQ, Elsaadawy E, Zhang JM, Vakarelski IU, Thoroddsen ST (2022) Coalescence time of water-in-oil emulsions under shear. Chem Eng Sci 250:117257

Toshev BV, Ivanov IB (1975) Thermodynamics of thin liquid films. Colloid Polym Sci 253(7):558–565

Urlaub J, Norwig J, Schollmayer C, Holzgrabe U (2019) 1H NMR analytical characterization of mineral oil hydrocarbons (PARAFFINS) for pharmaceutical use. Journal of Pharmaceutical and Biomedical Analysis 169:41–48

Vakarelski IU, Manica R, Tang X, O’Shea SJ, Stevens GW, Grieser F, Dagastine RR, Chan DYC (2010) Dynamic interactions between microbubbles in water. Proceedings of the National Academy of Sciences 107(25):11177–11182

Vermant J, Cioccolo G, Golapan Nair K, Moldenaers P (2004) Coalescence suppression in model immiscible polymer blends by nano-sized colloidal particles. Rheologica Acta 43(5):529–538

Vitry Y, Dorbolo S, Vermant J, Scheid B (2019) Controlling the lifetime of antibubbles. Advances in Colloid and Interface Science 270:73–86

Vrij A (1966) Possible mechanism for the spontaneous rupture of thin, free liquid films. Discussions of the Faraday Society 42:23–33

Yaminsky VV, Ohnishi S, Vogler EA, Horn RG (2010) Stability of aqueous films between bubbles. Part 1. The effect of speed on bubble coalescence in purified water and simple electrolyte solutions. Langmuir 26(11):8061–8074

Yang H, Park CC, Hu YT, Leal LG (2001) The coalescence of two equal-sized drops in a two-dimensional linear flow. Physics of Fluids 13(5):1087–1106

Yoon Y, Baldessari F, Ceniceros HD, Leal LG (2007) Coalescence of two equal-sized deformable drops in an axisymmetric flow. Physics of Fluids 19(10):102102

Yoon Y, Hsu A, Leal LG (2007) Experimental investigation of the effects of copolymer surfactants on flow-induced coalescence of drops. Physics of Fluids 19(2):023102

Zell ZA, Nowbahar A, Mansard V, Leal LG, Deshmukh SS, Mecca JM, Tucker CJ, Squires TM (2014) Surface shear inviscidity of soluble surfactants. Proceedings of the National Academy of Sciences 111(10):3677–3682

Zhang Z, Song J, Lin Y-J, Wang X, Biswal SL (2020) Comparing the coalescence rate of water-in-oil emulsions stabilized with asphaltenes and asphaltene-like molecules. Langmuir 36(27):7894–7900

Acknowledgements

EC and JV would like to thank the ETH Energy Science Center Partnership with Shell for the financial support. CSD would like to acknowledge that this material is based upon work supported by the Humphreys Engineer Center Support Activity under Contracts No. W912HQ20C0041, corresponding to DOD Strategic Environmental Research and Development Program (SERDP) projects WP19-1407. The DOD SERDP support includes support for YC. CSD would also like to acknowledge support by Donaldson Company, including support for RB.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

The original online version of this article was revised due to missing Supplementary Information movie files.

Supplementary information

Below is the link to the electronic supplementary material.

(AVI 3.97 MB)

(AVI 6.35 MB)

(AVI 6.52 MB)

(AVI 10.7 MB)

(AVI 4.03 MB)

(AVI 20.4 MB)

(AVI 781 KB)

(AVI 31.4 MB)

(MP4 1.66 MB)

(MP4 753 KB)

(MP4 424 KB)

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Chatzigiannakis, E., Chen, Y., Bachnak, R. et al. Studying coalescence at different lengthscales: from films to droplets. Rheol Acta 61, 745–759 (2022). https://doi.org/10.1007/s00397-022-01365-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00397-022-01365-w