Abstract

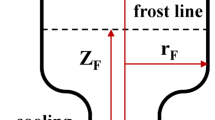

The two-phase microstructural/constitutive model for film blowing of Doufas and McHugh (D-M) (J Rheol 45:1085–1104, 2001a) is validated against online film data of a linear low-density polyethylene (LLDPE) at a variety of processing conditions. The D-M model includes the effects of thermal and flow-induced (enhanced) crystallization (FIC) coupled with the rheological response of both the melt and semicrystalline phases under fabrication conditions. The model predictions of bubble radius, velocity, and crystallinity profiles are in quantitative agreement with available experimental data over a wide range of blow-up ratios (BUR), take-up ratios (TUR), and bubble cooling rates using the same set of material/model parameters. The model naturally predicts the location of the frost line as a consequence of system stiffening due to crystallization overcoming the pitfalls of traditional modeling approaches that impose it as an artificial boundary condition. For a wide range of processing conditions, it is found that key film mechanical properties including elongation to break, yield stress, tensile modulus, and tear strength correlate well with predicted locked-in extensional stresses and molecular orientation at the frost line enabling development of quantitative structure-process-properties relationships that are useful in product and process development. The D-M model for film blowing is physics-based including elements of molecular rheology (polymer kinetic theory), suspension, and nucleation theories as well as irreversible thermodynamics principles, yet being tractable for continuum-based numerical simulations with practical industrial applicability. The FIC enhancement factor of the model is shown to be proportional to \(\exp \left (\lambda _{\text {eff},\textnormal {w}}^{2} -1\right )\), where λ eff,w is a molecular chain stretch ratio of the whole chain and proportional to exp (λ 2 − 1), where λ is the stretch ratio of the remaining (uncrystallized) amorphous chain, consistent with fundamental kinetic Monte Carlo simulations of flow-induced nucleation of Graham and Olmsted (Phys Rev Lett 103:115702-1–115702-4, 2009).

Similar content being viewed by others

References

Adamovsky SA, Minakov AA, Schick C (2003) Scanning microcalorimetry at high cooling rates. Thermochim Acta 403:55–63

Advani SG, Tucker CL III (1990) Closure approximations for three-dimensional structure tensor. J Rheol 34:367–386

Alamo RG, Viers BD, Mandelkern L (1995) A re-examination of the relation between the melting temperature and the crystallization temperature: linear polyethylene. Macromolecules 28:3205–3213

Ashok BK, Campbell GA (1992) Two-phase simulation of tubular film blowing of crystalline polymers. Int Polym Process 7:240–247

Beris AN, Edwards BJ (1994) Thermodynamics of flowing systems. Oxford

Bicerano J, Douglas JF, Brune DA (1999) Model for the viscosity of particle dispersions. Rev Macromol Chem Phys C39:561–642

Bird RB, Armstrong RC, Hassager O (1987a) Dynamics of polymeric liquids, fluid mechanics, vol 1, 2nd edn. Wiley, New York

Bird RB, Curtiss CF, Armstrong RC, Hassager O (1987b) Dynamics of polymeric liquids, kinetic theory, vol 2, 2nd edn. Wiley, New York

Bullwinkel MD, Campbell GA, Rasmussen DH, Krexa J, Brancewitz CL (2001) Crystallization studies of LLDPE during tubular blown film processing. Intern Polym Proc XVI:39–47

Chen HY, Bishop M, Landes B, Chum SP (2006) Orientation and property correlations for LLDPE blown films. J Applied Polym Sci 101:898–907

Cherukupalli SS (2004) Online measurements of microstructure using Raman spectroscopy during blown film extrusion of polyolefins. Ph.D. Dissertation, Clemson University, Clemson

Cherukupalli SS, Ogale AA (2004) Online measurements of crystallinity using Raman spectroscopy during blown film extrusion. Polym Eng Sci 44:1484–1490

Cherukupalli SS, Gottlieb SE, Ogale AA (2005) Real-time Raman spectroscopic measurement of crystallization kinetics and its effect on themorphology and properties of polyolefin blown films. J Applied Polym Sci 98:1740–1747

Cohen A (1991) A Pade approximant to the inverse Langevin function. Rheol Acta 30:270–273

Cox WP, Merz EH (1958) Correlation of dynamic and steady flow viscosities. J Polym Sci Polym Phys Ed 28:619–621

Cox C, Pearson S, von Oehsen J, Duffy E (2006) A fiber and film simulation package as a learning tool. SPE/ANTEC Tech Paper Proceedings, p 2417–2421

Cui K, Meng L, Tian N, Zhou W, Liu Y, Wang Z, He J, Li L (2012) Self-acceleration of nucleation and formation of shish in extension-induced crystallization with strain beyond fracture. Macromolecules 45:5477–5486

Dairanieh IS, McHugh AJ (1983) An analysis of local flow effects in flow-induced orientation and crystallization. J Polym Sci Polym Phys Ed 21:1473–1492

Derakhshandeh M, Hatzikiriakos SG (2012) Flow-induced crystallization of high-density polyethylene: the effects of shear and uniaxial extension. Rheol Acta 51:315–327

De Santis F, Adamosky S, Titomanlio G, Schick C (2006) Scanning nanocalorimetry at high cooling rate of isotactic polypropylene. Macromolecules 39:2562–2567

Di Lorenzo ML, Silvestre C (1999) Non-isothermal crystallization of polymers. Prog Polym Sci 24:917–950

Ding Z, Spruiell J (1996) An experimental method for studying nonisothermal crystallization of polymers at very high cooling rates. J Polym Sci Part B Polym Phys 34:2783–2804

Doufas AK (2006) Analysis of the rheotens experiment with viscoelastic constitutive equations for probing extensional rheology of polymer melts. J Rheol 50:749–769

Doufas AK, Butler T (2003) Simulation of blown film process of semi-crystalline processes. SPE/ANTEC Tech Paper Proceedings, p 3261–3265

Doufas AK, McHugh AJ (2001a) Simulation of film blowing including flow-induced crystallization. J Rheol 45:1085–1104

Doufas AK, McHugh AJ (2001b) Simulation of melt spinning including flow-induced crystallization. Part III. Quantitative comparisons with PET spinline data. J Rheol 45:403–420

Doufas AK, Dairanieh IS, McHugh AJ (1999) A continuum model for flow-induced crystallization of polymer melts. J Rheol 43:85–109

Doufas AK, McHugh AJ, Miller C (2000a) Simulation of melt spinning including flow-induced crystallization. Part I. Model development and predictions. J Non-Newton Fluid Mech 92:27–66

Doufas AK, McHugh AJ, Miller C, Immaneni A (2000b) Simulation of melt spinning including flow-induced crystallization. Part II. Quantitative comparisons with industrial spinline data. J Non-Newton Fluid Mech 92:81–103

Feng L, Kamal MR (2005) Crystallization and melting behavior of homogeneous and heterogeneous linear low-density polyethylene resins. Polym Eng Sci 45:1140–1151

Flory PJ (1953) Principles of polymer chemistry. Cornell University Press, Ithaca

Flory PJ (1955) Theory of crystallization in copolymers. Trans Faraday Soc 51:848–857

Flory PJ, Vrij A (1963) Melting points of linear-chain homologs. The normal paraffin hydrocarbons. Am Chem Soc 85:3548–3553

Graham RS, Olmsted PD (2009) Coarse-grained simulations of flow-induced nucleation in semicrystalline polymers. Phys Rev Lett 103:115702–1–115702–4

Gupta RK, Metzner AB, Wissbrun KF (1982) Modeling of polymeric film-blowing processes. Polym Eng Sci 22:172–181

Gururajan G, Ogale AA (2012) Real-time crystalline orientation measurements during low-density polyethylene blown film extrusion using Wide-Angle X-Ray diffraction. Polym Eng Sci 52:1532–1536

Gururajan G, Shan H, Lickfield G, Ogale AA (2008) Real-time wide-angle X-ray diffraction during polyethylene film blowing. Polym Eng Sci 48:1487–1494

Hadinata C, Boos D, Gabriel C, Wassner E, Rüllmann M, Kao N, Laun M (2007) Elongation-induced crystallization of a high molecular weight isotactic polybutene-1 melt compared to shear-induced crystallization. J Rheol 51:195–215

Hammami A, Spruiell JE (1995) Quiescent nonisothermal crystallization kinetics of isotactic polypropylene. Polym Eng Sci 35:797–804

Han CD, Kwack TH (1983) Rheology-processing-property relationships in tubular blown film extrusion. I. High-pressure low-density polyethylene. J Appl Polym Sci 28:3399–3418

Henrichsen LK (2006) Steady state modeling and dynamic analysis of film blowing. Ph.D. Dissertation, University of Illinois, Urbana, Illinois, USA

Henrichsen LK, McHugh AJ (2007) Analysis of film blowing with flow-enhanced crystallization. Intern Polym Processing XXII:179-189

Hoffman JD, Davis GT, Lauritzen JI Jr. (1976) The rate of crystallization of linear polymers with chain folding. In: Hannay, NB (ed) Treatise on solid state chemistry: crystalline and Non-crystalline solids, vol 3, ch 7. Plenum, New York

Jarecki L, Ziabicki A (2002) Development of molecular orientation and stress in biaxially deformed polymers. I. Affine deformation in a solid state. Polymer 43:2549–2559

Kanai T, White JL (1984) Kinematics, dynamics, and stability of the tubular film extrusion of various polyethylenes. Polym Eng Sci 24:1185–1201

Keller A, Kolnaar JWH (1993) Orientational phenomena in polymers. Springer, Berlin

Kim M-H, Phillips PJ, Lin JS (2000) The equilibrium melting points of random ethylene-octene copolymers: a test of the Flory and Sanchez-Eby theories. J Polym Sci Part B Polym Phys 38:154–170

Kolarik R, Zatloukal M (2011) Modeling of nonisothermal film blowing process for Non-Newtonian fluids by using variational principles. J Applied Poly Sci 122:2807–2820

Kolesov IS, Androsch R, Radusch H-J (2004) Non-isothermal crystallization of polyethylenes as function of cooling rate and concentration of short chain branches. J Therm Anal Cal 78:885–895

Kuijk EW, Tas PP, Neuteboom P (1999) A rheological model for the prediction of polyethylene blown film properties. J Reinf Plast Compos 18:508–517

Kwack TH, Han CD (1983) Rheology-processing-property relationships in tubular blown film extrusion. II. Low-pressure low-density polyethylene. J Appl Polym Sci 28:3419–3433

Kwack TH, Han CD, Vickers ME (1988) Development of crystalline structure during tubular film blowing of low-density polyethylene. J Appl Poly Sci 35:363–389

Lee JS, Jung HW, Hyun JC (2011) Transient solutions of nonlinear dynamics in film blowing process accompanied by on-line crystallization. J Rheol 55:257–271

Liu CC, Bogue DC, Spruiell JE (1995) Tubular film blowing. Part 2. Theoretical modeling. Int Polym Process 10:230–236

Mandelkern L (2004) Crystallization of polymers. In: Kinetics and mechanisms, vol 2, 2nd edn. Cambridge University Press, Cambridge

Marrucci G (1972) The free energy constitutive equation for polymer solutions from the dumbbell model. Trans Soc Rheol 16:321–331

McHugh AJ (1975) Flow-induced crystallization from solution: the relative effects of extension and shearing flow fields. J Appl Poly Sci 19:125–140

McHugh AJ (1982) Mechanisms of flow induced crystallization. Polym Eng Sci 22:15–26

McHugh AJ (1995) Flow-induced crystallization in polymers, rheo-physics of multiphase polymeric systems. In: Lyngaae-Jorgensen J, Sondergaard K (eds) TECHNOMIC. Lancaster

Menges G, Predöhl WO (1975) Certain aspects of filmblowing of low-density polyethylene. Polym Eng Sci 15:394–399

Metzner AB (1985) Rheology of suspensions in polymeric liquids. J Rheol 29:739–775

Mooney M (1951) The viscosity of concentrated suspension of spherical particles. J Colloid Sci 6:162–170

Mubarak Y, Harkin-Jones EMA, Martin PJ, Ahmad M (2001) Modeling of non-isothermal crystallization kinetics of isotactic polypropylene. Polymer 42:3171–3182

Muslet IA, Kamal MR (2004) Computer simulation of the film blowing process incorporating crystallization and viscoelasticity. J Rheol 48:525–550

Patel RM, Spruiell JE (1991) Crystallization kinetics during polymer processing—analysis of available approaches for process modeling. Polym Eng Sci 31:730–738

Patel RM, Doufas AK, Paradkar RP (2008) Raman spectroscopy for spin line crystallinity measurements. II. Validation of fundamental fiber spinning models. J Appl Polym Sci 109:3398–3412

Pearson JRA, Petrie CJS (1970) The flow of a tubular film. Part 1. Formal mathematical representation. J Fluid Mech 40:1–19

Peterlin A (1966) Hydrodynamics of linear macromolecules. Pure Appl Chem 12:563–586

Petrie CJS (1983) Film blowing, blow moulding and thermoforming. In: Pearson JRA, Richardson SM (eds) Computational analysis of polymer processing. Applied Science, London, pp 217–241

Pirkle JC, Braatz RD (2004) Comparison of the dynamic thin shell and quasi-cylindrical models for blown film extrusion. Polym Eng Sci 44:1267–1276

Pirkle JC, Braatz RD (2010) A thin-shell two-phase microstructural model for blown film extrusion. J Rheol 54:471–505

Pirkle JC, Braatz RD (2011) Instabilities and multiplicities in non-isothermal blown film extrusion including the effects of crystallization. J Process Control 21:405–414

Ran S, Zong X, Fang D, Hsiao BS, Chu B, Ross R (2000) Novel image analysis of two-dimensional X-ray fiber diffraction patterns: example of a polypropylene fiber drawing study. J Appl Cryst 33:1031–1036

Razavi-Nouri M, Hay JN (2007) Isothermal crystallization kinetics and melting behaviour of metallocene-catalyzed polyethylenes. Iran Polym J 13:521–530

Reid BO, Vadlamudi M, Mamun Al, Janani H, Gao H, Hu W, Alamo RG (2013) Strong memory effect of crystallization above the equilibrium melting point of random copolymers. Macromolecules 46:6485–6497

Rodriguez F (1996) Principles of polymer systems. Taylor & Francis, Washington

Roozemond PC, Steenbakkers RJA, Peters GWM (2011) A model for flow-enhanced nucleation based on fibrillar dormant precursors. Macromol Theory Simul 20:93–109

Sanchez IC, Eby RK (1975) Thermodynamics and crystallization of random copolymers. Macromolecules 8:638–641

Sarafrazi S, Sharif F (2008) Non-isothermal simulation of the film blowing process using multi-mode extended pom-pom model. Intern Polym Proces XXIII:30–37

Schneider W, Koeppl A, Berger J (1988) Non-isothermal crystallization of polymers. Intern Polym Proces 2:151–154

Sentmanat M, Delgadillo-Velázquez O, Hatzikiriakos SG (2010) Crystallization of an ethylene-based butane plastomer: the effect of uniaxial extension. Rheol Acta 49:931–939

Sidiropoulos V (2000) The effects of air cooling on the film blowing process. Ph.D. Dissertation, McMaster University, Hamilton

Somani RH, Yang L, Zhu L, Hsiao BS (2005) Flow-induced shish-kebab precursor structures in entangled polymer melts. Polymer 46:8587–8623

Springer H, Hengse A, Hohne J, Schich HG (1986) Investigation on crystallization and melting behavior of linear low density polyethylene (LLDPE). Progr Colloid Polymer Sci 72:101–105

Steenbakkers RJA, Peters GWM (2011) A stretch-based model for flow-induced nucleation of polymer melts. J Rheol 55:401–433

Supaphol P, Spruiell JE (1998) Nonisothermal bulk crystallization studies of high density polyethylene using light depolarizing microscopy. J Polym Sci Part B Polym Phys 36:681–692

Supaphol P, Spruiell JE (2002) Nonisothermal bulk crystallization of high-density polyethylene via a modified depolarized light microscopy technique: further analysis. J Applied Polym Sci 86:1009–1022

Tas P (1994) Film blowing: from polymer to product. Ph.D. Dissertation, Eindhoven University of Technology, Eindhoven

Thomas DG (1965) Transport characteristics of suspension: VIII. A note on the viscosity of Newtonian suspensions of uniform spherical particles. J Colloid Sci 20:267–277

van Meerveld J, Hutter M, Peters GWM (2008) A continuum model for the simulation of fiber spinning with quiescent and flow-induced crystallization. J Non-Newton Fluid Mech 150:177–195

Young RJ, Lovell PA (1991) Introduction to polymers, 2nd edn. Chapman & Hall, New York

Zheng R, Kennedy PK (2004) A model for post-flow induced crystallization: general equations and predictions. J Rheol 48:823–842

Ziabicki A (1976) Fundamentals of fiber formation. Interscience, New York

Acknowledgments

The author would like to express his appreciation to Braskem America for support of the earlier stages of this research. Fruitful discussions with Prof. Savvas Hatzikiriakos(University of British Columbia), Dr. Alexander Norman, and Dr. Ting Chen (Exxonmobil Chemical Company) are greatly appreciated. The author would also like to thank an anonymous reviewer for his/her comments that were addressed improving the quality of the manuscript significantly. An earlier version of this work was presented as an invited keynote paper at the Conference of the Canadian Society of Rhelogy at Montreal, Canada, June 2011.

Author information

Authors and Affiliations

Corresponding author

Appendix: Dimensionless variables and numbers

Appendix: Dimensionless variables and numbers

Dimensionless variables

The subscript “o” used in the definition of dimensionless variables and numbers below refers to the value of the respective variable at the die exit.

While the axial distance z is traditionally nondimensionalized with respect to the bubble radius at the die R o leading to a computational domain of z∗ > 1, the nondimensionalization of z with respect to L(distance from die exit to nip rolls) first proposed by Doufas and McHugh (2001a) is computationally more efficient, since it restricts the domain z* ∈ [0, 1].

The bubble axial velocity at the die exit v o is calculated from the mass flow rate W, the values of H o , R o and density ρ via the continuity equation

where K o is Hookean spring constant of the initially amorphous chains corresponding to N o statistical links and k B is the Boltzmann constant. We should note though that the tensor c* represents the remaining amorphous chains [N o (1 − x) statistical segments] upon inception of crystallization through the correction factor 1 − x in the evolution equations (4–6), the amorphous relaxation time expression (15) and the calculation of the nonlinear force E factor (7).

where G is a characteristic modulus of elasticity more representative of the long relaxation time tail (Doufas 2006). While G is taken constant in our calculations, the stiffening of the semicrystalline system is simulated through dependence of the relaxation times on crystallinity and temperature (14, 15) and increase of chain rigidity through the nonlinear force factor E (7).

Dimensionless numbers

Dimensionless number D 1 used in the momentum equations

Dimensionless numbers D 2 –D 5 used in the energy equation

where C p is the heat capacity

where σ B is the Stefan-Boltzmann constant, and ε is the emissivity.

where ΔH f is the heat of fusion and ∅ ∞ is the ultimate (maximum achievable) crystallinity with the absolute crystallinity ∅ given by ∅ = x∅ ∞.

Dimensionless number D c used in the evolution equations of c* tensor

where λ a (x, T) is calculated by Eq. 15.

Dimensionless numbers DS 1 and DS 2 used in the evolution equations of S tensor

where λ sc (x, T) is calculated by Eq. 14.

Dimensionless number D x used in the evolution equations of relative crystallinity x

where K av is given by Eq. 16.

Rights and permissions

About this article

Cite this article

Doufas, A.K. A microstructural flow-induced crystallization model for film blowing: validation with experimental data. Rheol Acta 53, 269–293 (2014). https://doi.org/10.1007/s00397-013-0749-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00397-013-0749-8