Abstract

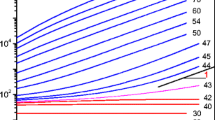

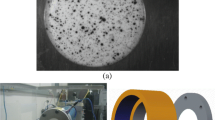

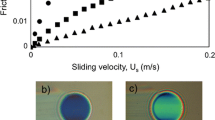

The displacement of an object through a yield stress is a complex process which involves the continuous deformation and transition of new regions from the solid to the liquid regime. We studied the force vs depth variations during the progressive penetration of a plate or a cylinder in a bath of simple yield stress fluids with negligible thixotropic character (Carbopol solutions, emulsions, and foams). Three regimes could be distinguished: elastic deformation, penetration (partially immersed object), and displacement through the fluid (fully immersed object). A detailed analysis of the force vs depth curves makes it possible to show that in the partially immersed regime the force is the sum of the critical force before penetration and a term associated with a uniform shear stress along the main plate surface, which is independent on the object geometry (plate dimensions and cylinder radius). This understanding can be used to precisely determine the yield stress as the critical shear stress along the plate at vanishing velocities. We also show that it is possible to measure accurately the yield stress from relaxation tests (stress vs time curve for motion stoppage): it indeed appears that the additional force term associated with penetration is negligible in that case so that the asymptotic average shear stress after stoppage is equal to the yield stress.

Similar content being viewed by others

References

Ansley RW, Smith TN (1967) Motion of spherical particles in a Bingham plastic. AIChE J 13:1193–1196

Beaulne M, Mitsoulis E (1997) Creeping motion of a sphere in tubes filled with Herschel–Bulkley fluids. J Non-Newt Fluid Mech 72:55–71

Beris AN, Tsamopoulos JA, Armstrong RC, Brown RA (1985) Creeping motion of a sphere through a Bingham Plastic. J Fluid Mech 158:219–244

Bertola V, Bertrand F, Tabuteau H, Bonn D, Coussot P (2003) Wall slip and yielding in pasty materials. J Rheol 47–61:1211

Bourne M (2002) Food texture and viscosity—concept and measurement. Academic, New York

Coussot P (2005) Rheometry of pastes, suspensions and granular materials. Wiley, New York

Coussot P, Tabuteau H, Chateau X, Tocquer L, Ovarlez O (2006) Aging and solid or liquid behavior in pastes. J Rheol 50:975–994

Coussot P, Tocquer L, Lanos C, Ovarlez O (2009) Macroscopic vs. local rheology of yield stress fluids. J Non-Newton Fluid Mech 158:85

De Kee D, Turcotte G, Fildey K, Harrison B (1980) New method for the determination yield stress. J Texture Stud 10:281–288

De Kee D, Kim YD, Nguyen QD (2007) Measuring rheological properties using a slotted plate device. Kor-Aust Rheol J 19:75–80

Höhler R, Cohen-Addad S (2005) Rheology of liquid foam. J Phys Condens Matter 17:R1041

Johnson KL (1987) Contact mechanics. Cambridge University Press, Cambridge

Lootens D, Jousset P, Martinie L, Roussel N, Flatt RJ ( 2009) Yield stress during setting of cement pastes from penetration tests. Cem Concr Res 39:401–408

Lowery B, Morrison JE (2002) Soil penetrometers and penetrability. In Methods of soil analysis, Part 4. Physical methods. In: Dane JH, Topp GC (eds) Soil Science Society of America, Inc., Madison, pp 363–388

Lohrenz J, Kurata F (1962) Design and evaluation of a new body for falling cylinderviscometers. AIChE J 8:2–190

Lohrenz J, Swift GW, Kurata F (1960), An experimental verified theoretical study of the falling cylinder viscometer. AIChE J 6:4–547

Moses GB, Puddington IE (1949) Flow properties of dispersions of calcium soaps in hydrocarbon oil. Can J Res B 27:616

Magnin A, Piau JM (1990) Cone-and-plate rheometry of yield stress fluids. Study of an aqueous gel. J Non-Newton Fluid Mech 36:85–108

Ovarlez G, Rodts S, Ragouilliaux A, Coussot P, Goyon J (2008) Wide-gap Couette flows of dense emulsions: local concentration measurements, and comparison between macroscopic and local constitutive law measurements through magnetic resonance imaging. Phys Rev E 78:036307

Ovarlez G, Krishan K, Cohen-Addad S (2010) Investigation of shear-banding in three-dimensional foams. EPL 91:68005

Park NA, Irvine TF, Gui F (1988) Yield stress measurements with the falling needle viscometer. In: Proc. Xth international congress on rheology, vol 2, pp 160–163

Park NA, Cho Y, Irvine TF (1990) Steady shear viscosity measurements of viscoelastic fluids with the falling needle viscometer. J Non-Newton Fluid Mech 34:351–357

Piau JM (2002) Viscoplastic boundary layer. J Non-Newton Fluid Mech 102:193

Piau JM (2007) Carbopol gels: elastoviscoplastic and slippery glasses made of individual swollen sponges meso- and macroscopic properties, constitutive equations and scaling laws. J Non-Newton Fluid Mech 144:1–29

Picart D, Manceau JP, Fauré A (2001) Penetroviscometer for Newtonian and viscoplastic fluids. Inst Sci Technol 29:169-184

Salençon J (1983) Calcul à la rupture et analyse limite. Presses de l’école nationale des ponts et chausses, Paris

Tchamba JC, Amziane S, Ovarlez G, Roussel N (2008) Lateral stress exerted by fresh fluid concrete on formwork: laboratory experiments. Cem Concr Res 38:459–466

Tokpavi D, Dodji L, Magnin A, Jay P (2008) Very slow flow of Bingham viscoplastic fluid around a circular cylinder. J Non-Newton Fluid Mech 154:65

Uhlherr PHT, Guo J, Fang T-N, Tiu C (2002) Static measurement of yield stress using a cylindrical penetrometer. Kor-Aust Rheol J 14:17–23

Zhang M, Ferraris CF, Zhu H, Picandet V, Peltz MA, Stutzman P, De Kee D (2010) Measurement of yield stress for concentrated suspensions using a plate device. Mater Struct 43:47–62

Zhu L, Sun N, Papadopoulos K, De Kee D (2001) A slotted plate device for measuring static yield stress. J Rheol 45:1105–1122

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Boujlel, J., Coussot, P. Measuring yield stress: a new, practical, and precise technique derived from detailed penetrometry analysis. Rheol Acta 51, 867–882 (2012). https://doi.org/10.1007/s00397-012-0643-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00397-012-0643-9