Abstract

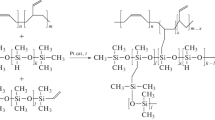

Thin film composites (TFCs) of poly(2-hydroxyethyl methacrylate) (PHEMA) and poly(methyl methacrylate) (PMMA) chain-tethered poly(vinylidene fluoride)-poly(dimethylsiloxane) (PVDF-PDMS) were prepared as a gas separation membrane. PDMS was coated on the PVDF support using a dip coating method. PHEMA and PMMA were then grafted on PVDF-PDMS substrate by atom transfer radical polymerization. The PVDF-PDMS-PHEMA and PVDF-PDMS-PMMA trilayer membranes were studied by attenuated total reflection Fourier transform infrared spectroscopy, scanning electron microscopy, atomic force microscopy, water contact angle measurement, and X-ray photoelectron spectroscopy. The results of separation tests indicated that the CO2/N2 selectivity of PVDF-PDMS-PHEMA and PVDF-PDMS-PMMA TFCs increased by ∼2 and ∼3 times, respectively, compared to the solvent-extracted PVDF-PDMS support.

Similar content being viewed by others

References

Chen HZ, Xiao YC, Chung TS (2011) Multi-layer composite hollow fiber membranes derived from poly(ethylene glycol) (PEG) containing hybrid materials for CO2/N2 separation J Membr Sci 381:211–220

Pinnau I, Wijmans JG, Blume I, Kuroda T, Peinemann KV (1988) Gas permeation through composite membranes J Membr Sci 37:81–88

Kattula M, Ponnuru K, Zhu L, Jia W, Lin H, Furlani EP (2015) Designing ultrathin film composite membranes: the impact of a gutter layer Sci Rep 5:15016

Liao S, Wang W, Uo M, Ohkawa S, Akasaka T, Tamura K, Cui F, Watari F (2005) A three-layered nano-carbonated hydroxyapatite/collagen/PLGA composite membrane for guided tissue regeneration Biomaterials 26:7564–7571

Henis JMS, Tripodi MK (1981) Composite hollow fiber membranes for gas separation: the resistance model approach J Membr Sci 8:233–246

Ulbricht M (2006) Advanced functional polymer membranes Polymer 47:2217–2262

Landrivon E, Miachon S, Kumakiri I, Matsukata M, Dalmon JA (2003) MFI-alumina composite membrane: influence of the support porous structure on the superlative performance Fuel Chem Div Prepr 48:394–395

Cybulski A, Moulijn JA, Stankiewicz A (2010) Novel concepts in catalysis and chemical reactors: improving the efficiency for the future. Wiley-VCH, Weinheim,

Shi E, Huang W, Xiao Z, Li D, Tang M (2007) Influence of binding interface between active and support layers in composite PDMS membranes on permeation performance J Appl Polym Sci 104:2468–2477

Mhlanga SD, Tshabalala TG, Nxumalo EN, Mamba BB (2014) Synthesis of PVDF ultrafiltration membranes supported on polyester fabrics for separation of organic matter from water IOP Conf Ser Mater Sci Eng 64:220–226

Zhou H, Lv L, Liu G, Jin W, Xing W (2014) PDMS/PVDF composite pervaporation membrane for the separation of dimethyl carbonate from a methanol solution J Membr Sci 471:47–55

Chung TS, Shieh JJ, Lau WWY, Srinivasan MP, Paul DR (1999) Fabrication of multi-layer composite hollow fiber membranes for gas separation J Membr Sci 152:211–225

Chung TS, Kafchiniski ER, Kohn RS, Foley P, Straff RS (1994) Fabrication of composite hollow fibers for air separation J Appl Polym Sci 53:701–708

Lundy KA, Cabasso I (1989) Analysis and construction of multilayer composite membranes for the separation of gas mixtures Ind Eng Chem Res 28:742–756

Gleason KK (2015) CVD polymers: fabrication of organic surfaces and devices. Wiley-VCH, Weinheim

Rijn CJMV (2004) Nano and micro engineered membrane technology from the membrane. Science and technology series. Elsevier, Amsterdam

J.S. Louie, Fouling-resistant coatings for reverse osmosis membranes: gas and liquid permeation studies on morphology and mass transport effects, Ph.D. thesis, Stanford University, 2008.

Marek M, Brynda E, Pientka Z, Schauer J (1997) Crosslinked ultra-thin polyimide film as a gas separation layer for composite membranes Eur Polym J 33:1717–1721

Dodda JM, Remis T, Tomas M, Novotny P (2016) Effect of alternation of polyamide selective layers in the formation and performance of thin-film composite membranes Desalin Water Treat 57:8720–8729

Ding C, Yin J, Deng B (2014) Effects of polysulfone (PSf) support layer on the performance of thin-film composite (TFC) membranes Chem Process Eng 1:1–8

Raymond PC, Paul DR (1990) Sorption and transport of pure gases in random styrene/methyl methacrylate copolymers J Polym Sci B Polym Phys 28:2079–2102

Chiou JS, Paul DR (1989) Gas sorption and permeation in poly(ethyl methacrylate) J Membr Sci 45:167–189

A. Sagle and B. Freeman, Fundamentals of membranes for water treatment, the future of desalination in Texas, 2004, 2, Report number 363, 137–154.

Baker RW (2004) Membrane technology and applications, 2nd edn. Wiley, New York

Yasuda HK (2005) Some important aspects of plasma polymerization Plasma Process Polym 2:293–304

Sapkal VS, Bansod PG, Sapkal RS (2011) Development of casting techniques for polyethersulfone ultra filtration membranes and their effects on flux and rejection Int J Chem Sci Appl 2:156–161

Saqib J, Aljundi IH (2016) Membrane fouling and modification using surface treatment and layer-by-layer assembly of polyelectrolytes: state-of-the-art review J Water Process Eng 11:68–87

Mittal V (2012) Polymer brushes: substrates, technologies, and properties. CRC, New York

Zeng F, Shen Y, Zhu S, Pelton R (2000) Atom transfer radical polymerization of 2-(dimethylamino) ethyl methacrylate in aqueous media J Polym Sci A Polym Chem 38:3821–3827

Balachandra AM, Baker GL, Bruening ML (2003) Preparation of composite membranes by atom transfer radical polymerization initiated from a porous support J Membr Sci 227:1–14

X. Dong, Reverse-selective gas separation membranes prepared by atom transfer radical polymerization, Ph.D. thesis, Michigan State University, 2012.

Yeon SH, Ahn SH, Kim JH, Lee KB, Jeong Y, Hong SU (2012) Synthesis and gas permeation properties of poly(vinyl chloride)-graft-poly(vinyl pyrrolidone) membranes Polym Adv Technol 23:516–521

Seiler DA (1997) PVDF in the chemical process industry. In: Scheirs J (ed) Modern fluoropolymers. Wiley, Chichester, pp. 487–505

Feijani EA, Tavasoli A, Mahdavi H (2015) Improving gas separation performance of poly(vinylidene fluoride) based mixed matrix membranes containing metal organic frameworks by chemical modification Ind Eng Chem Res 54:12124–12134

Ying L, Wang P, Kang ET, Neoh KG (2002) Synthesis and characterization of poly(acrylic acid)-graft-poly(vinylidene fluoride) copolymers and pH-sensitive membranes Macromolecules 35:673–679

Chen Y, Deng Q, Xiao J, Nie H, Wu L, Zhou W, Huang B (2007) Controlled grafting from poly(vinylidene fluoride) microfiltration membranes via reverse atom transfer radical polymerization and antifouling properties Polymer 48:7604–7613

Prajapati PK, Kansara AM, Singh PS (2016) Preparation and characterization of an oxygen permselective polydimethylsiloxane hollow fibre membrane RSC Adv 6:88943–88953

Gudernatsch W, Menzel T, Strathmann H (1991) Influence of composite membrane structure on pervaporation J Membr Sci 61:19–30

Pakizeh M, Mansoori SAA, Pourafshari Chenar M, Namvar-Mahboub M (2013) Modification of PSf membrane nanostructure using different fabrication parameters and investigation of the CO2 separation properties of PDMS-coated PSf composite membranes Braz J Chem Eng 30:345–354

Scofield JMP, Gurr PA, Kim J, Fu Q, Halim A, Kentish SE, Qiao GG (2015) High-performance thin film composite membranes with well-defined poly(dimethylsiloxane)-b-poly(ethylene glycol) copolymer additives for CO2 separation J Polym Sci A Polym Chem 53:1500–1511

Gongping L, Wang W, Wanqin J, Nanping X (2012) Polymer/ceramic composite membranes and their application in pervaporation process Chin J Chem Eng 20:62–70

Yampolskil Y (2010) Membrane gas separation. Wiley, Chichester

Reijerkerk SR, Knoef MH, Nijmeijer K, Wessling M (2010) Poly(ethylene glycol) and poly(dimethyl siloxane): combining their advantages into efficient CO2 gas separation membranes J Membr Sci 352:126–135

Dong W, Wang H, Ren F, Zhang J, He M, Wu T, Li Y (2016) Dramatic improvement in toughness of PLLA/PVDF blends: the effect of compatibilizer architectures ACS Sustain Chem Eng 4(8):4480–4489

Rumens CV, Ziai MA, Belsey KE, Batchelor JC, Holder SJ (2015) Swelling of PDMS networks in solvent vapours; applications for passive RFID wireless sensors J Mater Chem C 3:10091–10098

Maher BM, Rezaali J, Jalili K, Abbasi F (2016) Effects of various treatments on silicone rubber surface, rubber chemistry and technology. doi:10.5254/rct.16.83782

Emmenegger CR, Avramenko OA, Brynda E, Skvor J, Alles AB (2011) Poly(HEMA) brushes emerging as a new platform for direct detection of food pathogen in milk samples Biosens Bioelectron 26:4545–4551

Peter J, Peinemann KV (2009) Multilayer composite membranes for gas separation based on crosslinked PTMSP gutter layer and partially crosslinked Matrimid 5218 selective layer J Membr Sci 340:62–72

Sui X, Zapotoczny S, Benetti EM, Schön P, Vancso GJ (2010) Characterization and molecular engineering of surface-grafted polymer brushes across the length scales by atomic force microscopy J Mater Chem 20:4981–4993

Sun K, Yang W, Ma G, Wan F, Gao J, Lei Z, Guo H (2011) Preparation of tunable wettability polymer (ionic liquid) brushes at rough substrate using surface initiated atom transfer radical polymerization J Braz Chem Soc 22:478–483

S. Hansson, ARGET ATRP as a tool for cellulose modification, Ph.D. thesis, Kungliga Tekniska högskolan, Stockholm 2012.

Yang Y, Bittner AM, Baldelli S, Kern K (2008) Study of self-assembled triethoxysilane thin films made by casting neat reagents in ambient atmosphere Thin Solid Films 516:3948–3956

Lego B, Francois M, Skene WG, Giasson S (2009) Polymer brush covalently attached to OH-functionalized mica surface via surface-initiated ATRP: control of grafting density and polymer chain length Langmuir 25:5313–5321

Arkles B, Steinmetz JR, Zazycny J, Mehta P (1992) Factors contributing to the stability of alkoxysilanes in aqueous solution. In: Mittal KL (ed) Silanes and other coupling agents. VSP, Utrecht, pp. 91–104

Choi SH, Tasselli F, Jansen JC, Barbieri G, Drioli E (2010) Eur Polym J 46:1713–1725

Mark JE (2006) Physical properties of polymers handbook, 2nd edn. Springer, New York

Reddy BSR, Senthilkumar U (2003) Prospects of siloxane membrane technology for gas separation—a review J Sci Ind Res 62:666–677

Lee J, Park C, Whitesides G (2003) Solvent compatibility of PDMS-based microfluidic devices Anal Chem 75:6544–6554

Regehr KJ, Domenech M, Koepsel JT, Carver KC, Zelski SJE, Murphy WL, Schuler LA, Alarid ET, Beebe DJ (2009) Biological implications of polydimethylsiloxane-based microfluidic cell culture Lab Chip 9:2132–2139

Kim J, Chaudhury M, Owen MJ (2000) Hydrophobic recovery of polydimethylsiloxane J Colloid Interface Sci 226:231–236

Eddington D, Puccinelli J, Beebe D (2006) Sensors Actuators 114:170–172

Bodas D, Malek CK (2007) Hydrophilization and hydrophobic recovery of PDMS by oxygen plasma and chemical treatment- an SEM investigation Sensors Actuators B Chem 123:368–373

Li NN, Fane AG, Ho WSW, Matsuura T (2008) Advanced membrane technology and applications. Wiley, New Jersey

Ghosal K, Freeman BD (1994) Gas separation using polymer membranes: an overview Polym Adv Technol 5:673–697

Yampolskii YP, Pinnau I, Freeman BD (2006) Materials Science of membranes for gas and vapor separation. Wiley, Chichester

Ameri E, Sadeghi M, Zarei N, Pournaghshband A (2015) Enhancement of the gas separation properties of polyurethane membranes by alumina nanoparticles J Membr Sci 479:11–19

Gui X, Tang Z, Fei W (2011) Solubility of CO2 in alcohols, glycols, ethers, and ketones at high pressures from (288.15 to 318.15) K J Chem Eng Data 56:2420–2429

Sperling LH (1992) Introduction to physical polymer science. Wiley, New York

Lin H, Freeman BD (2005) Materials selection guidelines for membranes that remove CO2 from gas mixtures J Mol Struct 739:57–74

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Funding

This study was not funded by any institution.

Conflict of interest

The authors declare that they have no conflict of interest.

Electronic supplementary material

ESM 1

(DOCX 451 kb)

Rights and permissions

About this article

Cite this article

Maher, B.M., Rezaali, J., Ghaleh, H. et al. Evaluation of poly(2-hydroxyethyl methacrylate) and poly(methyl methacrylate)-grafted poly(vinylidene fluoride)-poly(dimethylsiloxane) bilayers for gas separation. Colloid Polym Sci 295, 1595–1607 (2017). https://doi.org/10.1007/s00396-017-4124-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00396-017-4124-7