Abstract

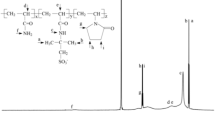

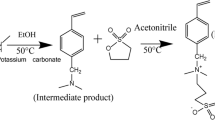

The zwitterionic copolymers are widely used for fluid loss additive in water-based drilling fluid due to their good performance in reducing the filtration loss and inhibiting the swelling of shales. However, there are still shortcomings to the conventional zwitterionic copolymer such as the poor properties of salt tolerance and thermal stability. This study synthesized a new kind of copolymer consisting of acrylamide (AM), 2-acryloylamino-2-methyl-1-propanesulfonic acid (AMPS), diallyl dimethyl ammonium chloride (DMDAAC), and the synthesized betaine-type monomer (vinylphenyl sulfonate (VPS)) (copolymer (PVAAD)) through introducing AMPS, DMDAAC, and VPS onto the backbone of AM via the method of free radical polymerization in aqueous solution. The biggest difference of PVAAD with the conventional zwitterionic copolymer is that there are zwitterions in the same chain and the different chain in the molecular structure of PVAAD. Results of performance evaluation show that the synthesized PVAAD used as fluid loss additive has good performances. It could be used as a fluid loss additive for water-based drilling fluid in salty and high-temperature environment. After adding 1.25 wt% of PVAAD, the structure of the filter cake of the copolymer drilling fluid system becomes relatively uniform and dense, and the particle size distribution of the freshwater drilling fluid tends to become more rational. Compared with the other commercial fluid loss additives, the synthesized PVAAD has a better property of high-temperature resistance and performance in controlling the American Petroleum Institute (API) filtration loss of drilling fluid systems.

Similar content being viewed by others

References

Hamed SB, Belhadri M (2009) Rheological properties of biopolymers drilling fluids. J Pet Sci Eng 67:84–90

Kelessidis VC, Poulakakis E, Chatzistamou V (2011) Use of Carbopol 980 and carboxymethyl cellulose polymers as rheology modifiers of sodium-bentonite water dispersions. ApplClaySci 54:63–69

Kosynkin DV, Ceriotti G, Wilson KC, et al. (2011) Graphene oxide as a high-performance fluid-loss-control additive in water-based drilling fluids. ACS ApplMaterInterfaces 4:222–227

Sadeghalvaad M, Sabbaghi S (2015) The effect of the TiO2/polyacrylamide nanocomposite on water-based drilling fluid properties. Powder Technol 272:113–119

Li MC, Wu Q, Song K, et al. (2015) Soy protein isolate as fluid loss additive in bentonite–water-based drilling fluids. ACS Appl Mater Interfaces 7:24799–24809

Amanullah M, AlArfaj MK, Al-abdullatif ZA (2011) Preliminary test results of nano-based drilling fluids for oil and gas field application[C]//SPE/IADC Drilling Conference and Exhibition. Soc. Petro. Eng.

Zakaria M, Husein MM, Harland G (2012) Novel nanoparticle-based drilling fluid with improved characteristics[C]//SPE International Oilfield Nanotechnology Conference and Exhibition. Soc. Petro. Eng.

Javeri SM, Haindade ZMW, Jere CB (2011) Mitigating loss circulation and differential sticking problems using silicon nanoparticles[C]//SPE/IADC Middle East Drilling Technology Conference and Exhibition. Soc. Petro. Eng.

Dias FTG, Souza RR, Lucas EF (2015) Influence of modified starches composition on their performance as fluid loss additives in invert-emulsion drilling fluids. Fuel 140:711–716

Navarrete RC, Himes RE, Seheult JM (2000) Applications of xanthan gum in fluid-loss control and related formation damage[C]//SPE Permian Basin Oil and Gas Recovery Conference. Soc. Petro. Eng.

Mao H, Qiu Z, Shen Z, et al. (2015) Hydrophobic associated polymer based silica nanoparticles composite with core–shell structure as a filtrate reducer for drilling fluid at ultra-high temperature. J Pet Sci Eng 129:1–14

Salami OT, Plank J (2016) Influence of electrolytes on the performance of a graft copolymer used as fluid loss additive in oil well cement. J Pet Sci Eng 143:86–94

Wan T, Yao J, Zishun S, et al. (2011) Solution and drilling fluid properties of water soluble AM–AA–SSS copolymers by inverse microemulsion. J Pet Sci Eng 78:334–337

Bu Y, Liu H, Nazari A, et al. (2016) Amphoteric ion polymer as fluid loss additive for phosphoaluminate cement in the presence of sodium hexametaphosphate. J Nat Gas SciEng 31:474–480

Sun J, Zeng F, Jian H, et al. (2013) Conjugation with betaine: a facile and effective approach to significant improvement of gene delivery properties of PEI. Biomacromolecules 14:728–736

Quintana R, Jańczewski D, Vasantha VA, et al. (2014) Sulfobetaine-based polymer brushes in marine environment: is there an effect of the polymerizable group on the antifouling performance. Colloids Surf, B:Biointerfaces 120:118–124

Wielema TA, Engberts JBFN (1987) Zwitterionic polymers-I. Synthesis of a novel series of poly (vinylsulphobetaines). Effect of structure of polymer on solubility in water. Eur Polym J 23:947–950

Dong C, Niu H, Dong JY (2014) “Two-in-one” catalysis of broad/bimodal molecular-weight-distribution polypropylene by a combination of Ziegler–Natta and metallocene catalysts. Appl Catal, A: General 484:142–147

Chen L, Ci T, Li T, et al. (2014) Effects of molecular weight distribution of amphiphilic block copolymers on their solubility, micellization, and temperature-induced sol–gel transition in water. Macromolecules 47:5895–5903

Zhong HY, Qiu ZS, Huang WA, et al. (2013) Inhibition comparison between polyether diamine and quaternary ammonium salt as shale inhibitor in water-based drilling fluid. Energy Sources, Part A: Recovery, Utilization, and Environmental Effects 35:218–225

Paswan BK, Jain R, Sharma SK, et al. (2016) Development of Jatropha oil-in-water emulsion drilling mud system. J Pet Sci Eng 144:10–18

ArablooNareh’ei M, PordelShahri M, Zamani M (2012) Rheological and filtration loss characteristics of colloidal gas aphron based drilling fluids. J JapPetrolInsti 55:182–190

Chu Q, Luo P, Zhao Q, et al. (2013) Application of a new family of organosilicon quadripolymer as a fluid loss additive for drilling fluid at high temperature. J Appl Polym Sci 128:28–40

de Rosangela CarvalhoBalaban R, Vidal ELF, Borges MR (2015) Design of experiments to evaluate clay swelling inhibition by different combinations of organic compounds and inorganic salts for application in water base drilling fluids. Appl Clay Sci 105:124–130

Wu YM, Sun DJ, Zhang BQ, et al. (2002) Properties of high-temperature drilling fluids incorporating disodium itaconate/acrylamide/sodium 2-acrylamido-2-methylpropanesulfonateterpolymers as fluid-loss reducers. J Appl Polym Sci 83:3068–3075

Bai X, Yang Y, Xiao D, et al. (2015) Synthesis, characterization, and performance evaluation of the AM/AMPS/DMDAAC/SSS quadripolymer as a fluid loss additive for water-based drilling fluid. J Appl Polym Sci 132

Wu YM, Zhang BQ, Wu T, et al. (2001) Properties of the forpolymer of N-vinylpyrrolidone with itaconic acid, acrylamide and 2-acrylamido-2-methyl-1-propane sulfonic acid as a fluid-loss reducer for drilling fluid at high temperatures. ColloidPolymSci 279:836–842

Takahashi K, Tezuka H, Satoh T, et al. (2009) Kinetic salt effects on an ionic reaction in ionic liquid/methanol mixtures-viscosity and Coulombic screening effects. Chem Lett 38:236–237

Peng B, Peng S, Long B, et al. (2010) Properties of high-temperature-resistant drilling fluids incorporating acrylamide/(acrylic acid)/(2-acrylamido-2-methyl-1-propane sulfonic acid) terpolymer and aluminum citrate as filtration control agents. J Vinyl AdditTechnol 16:84–89

Qu Y, Lai X, Zou L, et al. (2009) Polyoxyalkyleneamine as shale inhibitor in water-based drilling fluids. Appl Clay Sci 44:265–268

Jain R, Paswan BK, Mahto TK et al. (2015) Study the effect of synthesized graft copolymer on the inhibitive water based drilling fluid system. Egypt. J. Petrol.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Ma, X., Zhu, Z., Shi, W. et al. Synthesis and application of a novel betaine-type copolymer as fluid loss additive for water-based drilling fluid. Colloid Polym Sci 295, 53–66 (2017). https://doi.org/10.1007/s00396-016-3980-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00396-016-3980-x