Abstract

The interaction between drops and porous matter has important applications in many fields such as painting, paper coating, design of textiles, filtration and therapeutic delivery, the latter can include also reconstructive surgery processes. Since the phenomenon of droplet impact onto a porous surface is particularly complex, a first step consists in analysing impacts on 2D structures, such as metallic porous layers. The present paper shows the case of drop impacts onto metallic meshes attached to a solid substrate. The pores are squared and not planar, due to the woven structure of the meshes: the dynamics of the flow is particulary complex, but it resembles more realistic cases. In analysing the impact of droplets of water, acetone and a mixture of glycerol and water on meshes with different pore sizes, three main outcomes were observed for both test cases: deposition, partial imbibition and penetration. Higher velocity impacts lead to droplet splashing followed by deposition, partial imbibition and penetration. A higher amount of liquid penetration is linked to a higher velocity impact, lower viscosity and a larger dimension of the pore size. A map of the regimes is proposed introducing two dimensionless numbers M and γ, that are functions of the Weber and Reynolds numbers and pore and wire sizes. Previous papers have not considered the role of the wire diameter. The two numbers allow a clear separation of the outcomes and a practical use of the results.

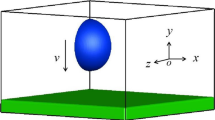

Graphical abstract

Similar content being viewed by others

Abbreviations

- d :

-

Droplet diameter (m)

- D p :

-

Pore equivalent diameter (m)

- D w :

-

Wire diameter (m)

- D*:

-

\(\frac{{d\left( t \right)}}{{{d_{\text{s}}}}}\)

- M :

-

\({\operatorname{Re} ^{0.9}}W{e^{2.1}}\)

- P c :

-

Capillary pressure (Pa)

- p d :

-

Dynamic pressure (Pa)

- Re :

-

Reynolds number with droplet diameter

- \(R{e_{\text{p}}}\) :

-

Reynolds number with pore diameter

- \({V_i}\) :

-

Impact velocity (m/s)

- We :

-

Weber number with droplet diameter

- \(W{e_{\text{p}}}\) :

-

Weber number with pore diameter

- \({{{\upgamma}}}\) :

-

\(1+\frac{{{D_{\text{w}}}}}{{{D_{{\text{pore}}}}}}\)

- µ :

-

Viscosity (Pa s)

- ρ :

-

Liquid density (kg/m3)

- σ :

-

Surface tension (N/m)

References

Bertola V (2008) some applications of controlled drop deposition on solid surfaces. Recent Patents Mech Eng 1:167–174. https://doi.org/10.2174/1874477X10801030167

Brunet P, Lapierre F, Zoueshtiagh F et al (2009) To grate a liquid into tiny droplets by its impact on a hydrophobic microgrid. Appl Phys Lett. https://doi.org/10.1063/1.3275709

Chandra S, Avedisian CT (1992) Observations of droplet impingement on a ceramic porous surface. Int J Heat Mass Transf 35:2377–2388. https://doi.org/10.1016/0017-9310(92)90080-C

Choi M, Son G, Shim W (2017) A level-set method for droplet impact and penetration into a porous medium. Comput Fluids 145:153–166. https://doi.org/10.1016/j.compfluid.2016.12.014

Clarke A, Blake TD, Carruthers K, Woodward A (2002) Spreading and imbibition of liquid droplets on porous surfaces. Langmuir 18:2980–2984. https://doi.org/10.1021/la0117810

Delbos A, Lorenceau E, Pitois O (2010) Forced impregnation of a capillary tube with drop impact. J Colloid Interface Sci 341:171–177. https://doi.org/10.1016/j.jcis.2009.09.016

Gambaryan-Roisman T (2014) Liquids on porous layers: wetting, imbibition and transport processes. Curr Opin Colloid Interface Sci 19:320–335. https://doi.org/10.1016/j.cocis.2014.09.001

He P, Liu Y, Qiao R (2015) Fluid dynamics of the droplet impact processes in cell printing. Microfluid Nanofluidics 18:569–585. https://doi.org/10.1007/s10404-014-1470-3

Hicks PD, Purvis R (2017) Gas-cushioned droplet impacts with a thin layer of porous media. J Eng Math 102:65–87. https://doi.org/10.1007/s10665-015-9821-y

Josserand C, Thoroddsen ST (2016) Drop impact on a solid surface. Annu Rev Fluid Mech 48:365–391. https://doi.org/10.1146/annurev-fluid-122414-034401

Karapetsas G, Chamakos NT, Papathanasiou AG (2016) Efficient modelling of droplet dynamics on complex surfaces. J Phys Condens Matter. https://doi.org/10.1088/0953-8984/28/8/085101

Kim WS, Lee SY (2014) Behavior of a water drop impinging on heated porous surfaces. Exp Therm Fluid Sci 55:62–70. https://doi.org/10.1016/j.expthermflusci.2014.02.023

Kumar SM, Deshpande AP (2006) Dynamics of drop spreading on fibrous porous media. Colloids Surf A Physicochem Eng Asp 277:157–163. https://doi.org/10.1016/j.colsurfa.2005.11.056

Lee JB, Radu AI, Vontobel P et al (2016) Absorption of impinging water droplet in porous stones. J Colloid Interface Sci 471:59–70. https://doi.org/10.1016/j.jcis.2016.03.002

Liu Y, Wang Z (2016) Superhydrophobic porous networks for enhanced droplet shedding. Sci Rep 6:1–7. https://doi.org/10.1038/srep33817

Lorenceau É, Quéré D (2003) Drops impacting a sieve. J Colloid Interface Sci 263:244–249. https://doi.org/10.1016/S0021-9797(03)00126-7

Mazloomi Moqaddam A, Chikatamarla SS, Karlin IV (2017) Drops bouncing off macro-Textured superhydrophobic surfaces. J Fluid Mech 824:866–885. https://doi.org/10.1017/jfm.2017.306

Pasandideh-Fard M, Qiao YM, Chandra S, Mostaghimi J (1996) Capillary effects during droplet impact on a solid surface. Phys Fluids 8:650–659

Pittoni PG, Lin Y, Lin S (2014) The impalement of water drops impinging onto hydrophobic/superhydrophobic graphite surfaces: the role of dynamic pressure, hammer pressure and liquid penetration time. Appl Surf Sci 301:515–524. https://doi.org/10.1016/j.apsusc.2014.02.115

Reis NC, Griffiths RF, Santos JM (2004) Numerical simulation of the impact of liquid droplets on porous surfaces. J Comput Phys 198:747–770. https://doi.org/10.1016/j.jcp.2004.01.024

Rioboo R, Tropea C, Marengo M (2001) Outcomes from a drop impact on solid surfaces. At Sprays 11:12. https://doi.org/10.1615/AtomizSpr.v11.i2.40

Rioboo R, Marengo M, Tropea C (2002) Time evolution of liquid drop impact onto solid, dry surfaces. Exp Fluids 33:112–124. https://doi.org/10.1007/s00348-002-0431-x

Roisman IV, Lembach A, Tropea C (2015) Drop splashing induced by target roughness and porosity: the size plays no role. Adv Colloid Interface Sci 222:615–621. https://doi.org/10.1016/j.cis.2015.02.004

Romdhani Z, Baffoun A, Hamdaoui M, Roudesli S (2014) Drop impact on textile material: effect of fabric properties. Autex Res J 14:145–151. https://doi.org/10.2478/aut-2014-0010

Ryu S, Sen P, Nam Y, Lee C (2017) Water penetration through a superhydrophobic mesh during a drop impact. Phys Rev Lett 118:1–5. https://doi.org/10.1103/PhysRevLett.118.014501

Sahu RP, Sett S, Yarin AL, Pourdeyhimi B (2015) Impact of aqueous suspension drops onto non-wettable porous membranes: hydrodynamic focusing and penetration of nanoparticles. Colloids Surf A Physicochem Eng Asp 467:31–45. https://doi.org/10.1016/j.colsurfa.2014.11.023

Weclas M (2010) Potential of porous-media combustion technology as applied to internal combustion engines. J Thermodyn 2010:1–39. https://doi.org/10.1155/2010/789262

Xu J, Xie J, He X et al (2017) Water drop impacts on a single-layer of mesh screen membrane: effect of water hammer pressure and advancing contact angles. Exp Therm Fluid Sci 82:83–93. https://doi.org/10.1016/j.expthermflusci.2016.11.006

Yamamoto K, Takezawa H, Ogata S (2016) Droplet impact on textured surfaces composed of commercial stainless razor blades. Colloids Surf A Physicochem Eng Asp 506:363–370. https://doi.org/10.1016/j.colsurfa.2016.06.024

Yarin AL (2006) Drop impact dynamics: splashing, spreading, receding, bouncing…. Annu Rev Fluid Mech 38:159–192. https://doi.org/10.1146/annurev.fluid.38.050304.092144

Yarin AL, Roisman IV, Tropea C (2017) Collision phenomena in liquids and solids. Cambridge University Press, Cambridge

Zhang R, Farokhirad S, Lee T, Koplik J (2014) Multiscale liquid drop impact on wettable and textured surfaces. Phys Fluids. https://doi.org/10.1063/1.4892083

Zhang G, Quetzeri-Santiago MA, Stone CA et al (2018) Droplet impact dynamics on textiles. Soft Matter. https://doi.org/10.1039/C8SM01082J

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Boscariol, C., Chandra, S., Sarker, D. et al. Drop impact onto attached metallic meshes: liquid penetration and spreading. Exp Fluids 59, 189 (2018). https://doi.org/10.1007/s00348-018-2640-y

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00348-018-2640-y