Abstract

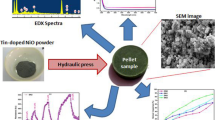

In the present work, nanostructured nickel oxide (NiO) powder has been synthesized using the sol–gel method and is annealed at different temperatures to study the impact of annealing temperature on its structural, optical, morphological, and LPG sensing properties. The obtained powder was analyzed by several characterization techniques such as field-emission scanning electron microscopy (FESEM), X-ray diffraction (XRD), UV–Visible spectroscopy (UV–Vis), particle analyzer, and Fourier-transform infrared spectroscopy. XRD patterns show that NiO nanoparticles have a cubic unit cell structure. The average crystallite size for each of the samples was calculated to be 27–77 nm using the Debye–Scherrer formula and Williamson-Hall uniform deformation model plot. FESEM images revealed the mesoporous morphology of prepared NiO nanoparticles and found that the particle size increases with an increase in annealing temperature. The UV–Vis absorption spectrum shows that the energy band gap decreases with an increase in annealing temperature for NiO nanoparticles. Liquefied petroleum gas (LPG) sensing properties of the prepared pellets were also examined at room temperature (300 K) in the range of 0.5–2.0 vol% concentration of LPG. The gas sensing response of the NiO:500 sample is 244.4% which is the highest among all the samples due to the combined effect of nanocrystal defects and specific surface area. The sensing response of the synthesized material increased significantly as the concentration of the test gas rose.

Similar content being viewed by others

References:

E.S. Snow, F.K. Perkins, J.A. Robinson, Chem. Soc. Rev. 35(9), 790–798 (2006). https://doi.org/10.1039/B515473C

J. Wang, F. Yang, X. Wei, Y. Zhang, L. Wei, J. Zhang, Q. Tang, B. Guo, Xu. Lei, Phys. Chem. Chem. Phys. 16(31), 16711–16718 (2014). https://doi.org/10.1039/C4CP01122H

L. Francioso, A.M. Taurino, A. Forleo, P. Siciliano, Sens. Actuators. B. Chem 130(1), 70–76 (2008). https://doi.org/10.1016/j.snb.2007.07.074

H.R. Kim, A. Haensch, I.I.-D. Kim, N. Barsan, U. Weimar, J.H. Lee, Adv. Func. Mater. 21(23), 4456–4463 (2011). https://doi.org/10.1002/adfm.201101154

Y. Zhang, Z. Zheng, F. Yang, Ind. Eng. Chem. Res. 49(8), 3539–3543 (2010). https://doi.org/10.1021/ie100197b

J. Wang, L. Wei, L. Zhang, J. Zhang, H. Wei, C. Jiang, Y. Zhang, J. Mater. Chem. 22(37), 20038–20047 (2012). https://doi.org/10.1039/C2JM34192A

K. Kumar, U. Kumar, M. Singh, B.C. Yadav, J. Mater. Sci.: Mater. Electron. 30(14), 13013–13023 (2019). https://doi.org/10.1007/s10854-019-01663-9

S. Singh, U. Kumar, B.C. Yadav, K. Kumar, R. Tripathi, K. Singh, Results. Phys 15, 102772 (2019). https://doi.org/10.1016/j.rinp.2019.1027

K. Kumar, A. Singh, U. Kumar, R.K. Tripathi, B.C. Yadav, J. Mater. Sci.: Mater. Electron. 31, 10836–10845 (2020). https://doi.org/10.1007/s10854-020-03635-w

D.-L. Sun, B.-W. Zhao, Jing-Bing. Liu et al., Ionics (2017). https://doi.org/10.1007/s11581-017-1974-4

J.G. Cook, F.P. Koffyberg, Sol. Energy. Mater 10(1), 55–67 (1984). https://doi.org/10.1016/0165-1633(84)90008-X

J.C.N. Botejue, A.C.C. Tseung, J. Electrochem. Soc. 132, 2957 (1985)

M. Bonomo, D. Dini, F. Decker, Front. Chem. 6, 601 (2018). https://doi.org/10.3389/fchem.2018.00601

A.K. Rai, L.T. Anh, C.J. Park, J. Kimm, Ceram. Int 39(6), 6611–6618 (2013). https://doi.org/10.1016/j.ceramint.2013.01.097

D. V. Ahire, G. E. Patil, G. H. Jain and V. B. Gaikwad, Sixth International Conference on Sensing Technology (ICST) Kolkata pp. 136–141 (2012) https://doi.org/10.1109/ICSensT.2012.6461656

Z.M. Khoshhesab, M. Sarfaraz, Synth. Reactivity. Inorg, Metal-Org, Nano-Metal. Chem 40(9), 700–703 (2010). https://doi.org/10.1080/15533174.2010.509710

N.N. MohdZorkipli, N.H.M. Kaus, A.A. Mohamad, Procedia. Chemistry 19, 626–631 (2016). https://doi.org/10.1016/j.proche.2016.03.062

L.G. Teoh, K.D. Li, Mater. Trans. 53(12), 2135–2140 (2012). https://doi.org/10.2320/matertrans.M2012244

P.K. Singh, N. Singh, M. Singh et al., Appl. Phys. A 126, 321 (2020). https://doi.org/10.1007/s00339-020-3439-2

B. Chaitongrat, S. Chaisitsak, J. Nanomaterials (2018). https://doi.org/10.1155/2018/9236450

K.V. Gurav, S.W. Shin, U.M. Patil, P.R. Deshmukh, M.P. Suryawanshi, G.L. Agawane, S.M. Pawar, P.S. Patil, J.Y. Lee, C.D. Lokhande, J.H. Kim, Sens. Actuators, B Chem. 190, 408–413 (2014). https://doi.org/10.1016/j.snb.2013.08.064

S.S. Barkade, D.V. Pinjari, U.T. Nakate, A.K. Singh, P.R. Gogate, J.B. Naik, S.H. Sonawane, A.B. Pandit, Chem. Eng. Process. 74, 115–223 (2013). https://doi.org/10.1016/j.cep.2013.09.005

M. Singh, B.C. Yadav, A. Ranjan, M. Kaur, S.K. Gupta, Sens. Actuators B: Chem 241, 1170–1178 (2017). https://doi.org/10.1016/j.snb.2016.10.018

H.A. Dehkordi, K. Dastafkan, A. Moshaii et al., J. Mater. Sci: Mater. Electron 26, 3134–3142 (2015). https://doi.org/10.1007/s10854-015-2808-7

A.K. Zak, W.A. Majid, M.E. Abrishami, R. Yousefi, Solid. State. Sci. 13(1), 251–256 (2011). https://doi.org/10.1016/j.solidstatesciences.2010.11.024

K.D. Roger, P. Daniels, Bio. Mater 23, 2577–2585 (2002). https://doi.org/10.1016/s0142-9612(01)00395-7

C. Amutha, S. Thanikaikarasan, V. Ramadas, S.A. Bahadur, B. Natarajan, R. Kalyani, Optik 127(10), 4281–4286 (2016). https://doi.org/10.1016/j.ijleo.2016.01.124

P. Gupta, N.K. Pandey, K. Kuldeep, B.C. Yadav, Sens. Actuators. A: Phys 319, 112484 (2021). https://doi.org/10.1016/j.sna.2020.112484

K. Venkateswarlu, A.C. Bose, N. Rameshbabu, Physica B 405(20), 4256–4261 (2010). https://doi.org/10.1016/j.physb.2010.07.020

S. Sivasankaran, K. Sivaprasad, R. Narayanasamy, P.V. Satyanarayana, Mater. Charact. 62(7), 661–672 (2011). https://doi.org/10.1016/j.matchar.2011.04.017

M. Dhongal, A. El-Denglawey, A.F. Elhady, A.A. Abuelwafa, Curr. Appl. Phys 12(5), 1334–1339 (2012). https://doi.org/10.1016/j.cap.2012.03.022

S. Kumar, Z.H. Khan, M.A.M. Khan, M. Husain, Curr. Appl. Phys 5(6), 561–566 (2005). https://doi.org/10.1016/j.cap.2004.07.001

R. Kumar, R. Das, M. Gupta, V. Ganesan, Superlattices Microstruct. 59, 29 (2013). https://doi.org/10.1016/j.spmi.2013.04.002

M. Saleem, L. Fang, H.B. Ruan, F. Wu, Q.L. Huang, C.L. Xu, C.Y. Kong, Int J. Phys Sci 7(23), 2971 (2012). https://doi.org/10.5897/IJPS12.219

S.S. Juliet, S. Ramalingom, C. Ravidhas, A.M.E. Raj, IOSR-JAP 9, 32–39 (2017). https://doi.org/10.9790/4861-0904043239

B.C. Yadav, S.R. Sabhajeet, R.K. Sonkar, J Mater Sci Res JMSR 108 (2018). https://doi.org/10.29011/JMSR-108/100008

F. Davar, Z. Fereshteh, M. Salavati-Niasari, J. Alloys. Compd 476, 797–801 (2009). https://doi.org/10.1016/j.jallcom.2008.09.121

M. Naseem Siddique, Ateeq Ahmed, T. Ali, and P. Tripathi, AIP Conference Proceedings 1953, 030027 (2018) DOI: https://doi.org/10.1063/1.5032362

R.O. Yathisha, Y. ArthobaNayaka, J. Mater. Sci (2018). https://doi.org/10.1007/s10853-017-1496-5

D.R. Miller, S.A. Akbar, P.A. Morris, D.R. Miller, S.A. Akbar, P.A. Morris, Sens. Actuators. B: Chem 204, 250–272 (2014). https://doi.org/10.1016/j.snb.2014.07.074

H.J. Kim, J.H. Lee, Sens. Actuators B: Chem 192, 607–627 (2014). https://doi.org/10.1016/j.snb.2013.11.005

P. Chou et al., IEEE Sens J 15(7), 3711–3715 (2015). https://doi.org/10.1109/JSEN.2015.2391286

P. Gupta, S. Maurya, N.K. Pandey, V. Verma, J. Mater. Sci: Mater. Electron (2021). https://doi.org/10.1007/s10854-020-05099-4

N. Barsan, U. Weimar, J. Electroceram. 7, 143–167 (2001). https://doi.org/10.1023/A:1014405811371

P. Gupta, S. Maurya, K.P. Narendra, V. Vernica, Nanosci. Nanotech-Asia 10, 1 (2020). https://doi.org/10.2174/2210681210999200718005402

R.W.J. Scott, S.M. Yang, G. Chabanis, N. Coombs, D.E. Williams, G.A. Ozin, Adv. Mater. 13, 1468–1472 (2001). https://doi.org/10.1002/1521-4095(200110)13:19

E. Wongrat, P. Pimpang, S. Choopun, Appl. Surf. Sci. 256, 968–971 (2009). https://doi.org/10.1016/j.apsusc.2009.02.046

Fu. Qingjie, M. Ai, Yi. Duan, Lu. Lingmei, X. Tian, D. Sun, Xu. Yanyan, Y. Sun, RSC. Adv. 7(82), 52312–52320 (2017). https://doi.org/10.1039/C7RA10730G

Acknowledgements

Authors appreciatively acknowledge to Department of Physics, University of Lucknow for providing XRD facility. MCN for this manuscript is IU/R&D/2020-MCN000988.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gupta, P., Kumar, K., Pandey, N.K. et al. Effect of annealing temperature on a highly sensitive nickel oxide-based LPG sensor operated at room temperature. Appl. Phys. A 127, 289 (2021). https://doi.org/10.1007/s00339-021-04444-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-021-04444-6