Abstract

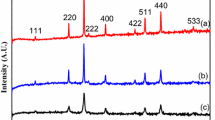

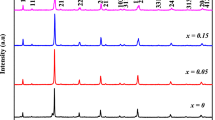

Structural and magnetic properties of as-prepared and annealed MgFe2O4 nano-powders prepared by auto-combustion method using dl-alanine fuel have been investigated. Nanoparticles with single-crystal electron diffraction patterns are analyzed, and phase purity is confirmed by X-ray diffraction and Raman and infrared spectroscopy. Residual carbon (C), hydrogen (H) and nitrogen (N) content in as-prepared powders is found to reduce by annealing the powders at 900 °C in air. Annealing the as-prepared powders in the range (600–1200 °C) increases the crystallite size from 35 to 46 nm, and increases saturation magnetization to 36 emu/g with low coercivity of ~ 33 Oe. Variations in the magnetic properties are correlated with changes in cation distribution in the octahedral and tetrahedral sites estimated from X-ray diffraction and magnetic studies.

Similar content being viewed by others

Change history

20 August 2021

A Correction to this paper has been published: https://doi.org/10.1007/s00339-021-04764-7

References

L. Thourel, The Use of Ferrites at Microwave Frequencies (Pergamon Press, New York, 1964).

M. Sugimoto, The past, present and future of ferrites. J. Am. Ceram. Soc. 82, 269–280 (1999). https://doi.org/10.1111/j.1551-2916.1999.tb20058.x

R. Vlenzuela, Novel applications of ferrites. Phys. Res. Int. (2012). https://doi.org/10.1155/2012/591839

M. Bououdina, B. Al-Najar, L. Falamarzi, J.J. Vijaya, M.N. Shaikh, S. Bellucci, Eur. Phys. J. Plus 134, 84 (2019). https://doi.org/10.1140/epjp/i2019-12485-5

P. Dhiman, N. Dhiman, A. Kumar, G. Sharma, M. Naushad, A.A. Ghfar, J. Mol. Liq. 294, 111574 (2019). https://doi.org/10.1016/j.molliq.2019.111574

N. Huo, Y. Yin, W. Liu, J. Zhang, Y. Ding, Q. Wang, Z. Shi, S. Yang, New. J. Chem. 40, 7068 (2016). https://doi.org/10.1039/C6NJ00084C

M. Gateshki, V. Petkov, S.K. Pradhan, T. Vogt, J. Appl. Cryst. 38, 772–779 (2005). https://doi.org/10.1107/S0021889805024477

E. Greenberg, W.M. Xu, M. Nikolaevsky, E. Bykova, G. Garbarino, K. Glazyrin, D.G. Merkel, L. Dubrovinsky, M.P. Pasternak, GKh. Rozenberg, Phys. Rev. B 95, 195150 (2017). https://doi.org/10.1103/PhysRevB.95.195150

A. Franco, M.S. Silva, J. Appl. Phys. 109, 07B505 (2011). https://doi.org/10.1063/1.3536790

T. Tatarchuk, M. Myslin, I. Mironyuk, M. Bououdina, A.T. Pedziwiatr, R. Gargula, B.F. Bogacaz, P. Kurzydlo, J. Alloys Compd. 819, 152945 (2020). https://doi.org/10.1016/j.jallcom.2019.152945

S.K. Pradhan, S. Bid, M. Gateshki, V. Petkov, Mater. Chem. Phys. 93, 224–230 (2005). https://doi.org/10.1016/j.matchemphys.2005.03.017

S. Manesiri, M. Sangmanee, A. Wiengmoon, Nanoscale Res. Lett. 4, 221–228 (2019). https://doi.org/10.1007/s11671-008-9229-y

Z. Yan, J. Gao, Y. Li, M. Zhang, M. Guo, RSC Adv. 5, 92778–92787 (2005). https://doi.org/10.1039/C5RA17145H

I. Bergmann, V. Šepelák, K.D. Becker, Solid State Ion. 117, 1865–1968 (2006). https://doi.org/10.1016/j.ssi.2006.04.002

V. Šepelák, F. Krumeich, F.J. Litterst, K.D. Becker, J. Appl. Phys. 88, 5884 (2000). https://doi.org/10.1063/1.1316048

R.A. Candeia, M.A.F. Souza, M.I.B. Bernardi, S.C. Maestrelli, I.M.G. Santos, A.G. Souza, E. Longo, Mater. Res. Bull. 41, 183–190 (2006). https://doi.org/10.1016/j.materresbull.2005.07.019

H. Aono, H. Hirazawa, T. Naohara, T. Maehara, Appl. Surf. Sci. 254, 2319–2324 (2008). https://doi.org/10.1016/j.apsusc.2007.09.024

P. Heidari, S.M. Masoudpanah, J. Mater. Res. Technol. 9, 4469–4475 (2020). https://doi.org/10.1016/j.jmrt.2020.02.073

C. Murugesan, L. Okrasa, G. Chandrasekharan, J. Supercond. Nov. Magn. 31, 3255–3262 (2018). https://doi.org/10.1007/s10948-018-4573-3

D.K. Mahato, S. Majumder, S. Banerjee, Appl. Surf. Sci. 413, 149–159 (2017). https://doi.org/10.1016/j.apsusc.2017.04.021

A.C. Druc, A.M. Dumitrescu, A.I. Borhan, V. Nica, A.R. Irodan, M.N. Palamaru, Cent. Eur. J. Chem. 11, 1330–1342 (2013). https://doi.org/10.2478/s11532-013-0260-1

J. Chandradass, A.H. Jadhav, K.H. Kim, H. Kim, J. Alloys Compd. 517, 164–169 (2012). https://doi.org/10.1016/j.jallcom.2011.12.071

A. Pradeep, P. Priyadarshini, G. Chandrasekaran, J. Magn. Magn. Mater. 320, 2774–2779 (2008). https://doi.org/10.1016/j.jmmm.2008.06.012

Y. Huang, Y. Tang, J. Wang, Q. Chen, Mater. Chem. Phys. 97, 394–397 (2006). https://doi.org/10.1016/j.matchemphys.2005.08.035

V.M. Khot, A.B. Salunkhe, M.R. Phadatare, S.H. Pawar, Mater. Chem. Phys. 132, 782–787 (2012). https://doi.org/10.1016/j.matchemphys.2011.12.012

S. Upadhyay, K. Sreenivas, J. Atomic Mol. Condens. Nano Phys. 2, 101–108 (2015). https://www.rgnpublications.com/journals/index.php/jamcnp/article/view/330/0

E.A. Chavarriaga, A.A. Lopera, V. Franco, C.P. Bergmann, J. Alarcon, J. Magn. Magn. Mater. 497, 166054 (2020). https://doi.org/10.1016/j.jmmm.2019.166054

S. Thankachan, S. Xavier, B. Jacob, E.M. Mohammed, J. Exp. Nanosci. 8, 347. – 357 (2013). https://doi.org/10.1080/17458080.2012.690892

S.D. Dalt, A.S. Takimi, T.M. Volkmer, V.C. Sousa, C.P. Bergmann, Powder Technol. 210, 103–108 (2011). https://doi.org/10.1016/j.powtec.2011.03.001

R. Köferstein, T. Walther, D. Hesse, S.G. Ebbinghaus, J. Mater. Sci. 48, 6509–6518 (2013). https://doi.org/10.1007/s10853-013-7447-x

T. Prabhakaran, J. Hemalatha, J. Alloys Compd. 509, 7071–7077 (2011). https://doi.org/10.1016/j.jallcom.2011.03.176

L. Chauhan, A.K. Shukla, K. Sreenivas, Ceram. Int. 42, 12136–12147 (2016). https://doi.org/10.1016/j.ceramint.2016.04.146

B.D. Cullity, C.D. Graham, Introduction to Magnetic Materials (Wiley, New York, 1972).

K. Momma, F. Izumi, J. Appl. Crystallogr. 44, 1272–1276 (2011). https://doi.org/10.1107/S0021889811038970

J. Smith, H.P.J. Wijn, Ferrites (Philips Technical Library, Eindhoven, 1959).

M. Klinger, A. Jäger, J. Appl. Cryst. 48, 2012–2108 (2015). https://doi.org/10.1107/S1600576715017252

W.B. White, B.A. DeAngelis, Spectochem. Acta 23A, 985–995 (1967). https://doi.org/10.1016/0584-8539(67)80023-0

Z. Wang, P. Lazor, S.K. Saxena, H.S.C. O’Neill, Mater. Res. Bull. 37, 1580–1602 (2002). https://doi.org/10.1016/S0025-5408(02)00819-X

C. Murugesan, L. Okrasa, G. Chandrashekaran, J. Mater. Sci. Mater. Electron. 28, 13168–13175 (2017). https://doi.org/10.1007/s10854-017-7152-7

A.M. Moustafa, L.M. Salah, M. Salerno, M.H. Abdellatif, J. Magn. Magn. Mater. 513, 167267 (2020). https://doi.org/10.1016/j.jmmm.2020.167267

P. Heidari, S.M. Masoudpanah, J. Phys. Chem. Solid 148, 109681 (2021). https://doi.org/10.1016/j.jpcs.2020.109681

A.C. Druc, A.I. Borhan, G.G. Nedelcu, L. Leonite, A.R. Iordan, M.N. Palamaru, Mater. Res. Bull. 48, 4647–4654 (2013). https://doi.org/10.1016/j.materresbull.2013.08.002

M. Ounacer, A. Essoumhi, M. Sajiddine, A. Razouk, A. Fnidiki, F. Richomme, J. Juraszek, S.M. Dubiel, M. Sahlaoui, J. Phys. Chem. Solid 148, 109687 (2021). https://doi.org/10.1016/j.jpcs.2020.109687

Acknowledgements

The authors thank the University Science Instrumentation Center (USIC), University of Delhi, Delhi—110007, India for the use of some characterization techniques. One of the authors Sudhanshu Kumar is thankful to Council of Scientific and Industrial research (CSIR), India for the award of Junior Research Fellowship (JRF) and Senior Research Fellowship (SRF) File No: 09/045(1595)/2018-EMR-I. The authors also thank Prof. Miloslav Kliner and A. Jageer, Institute of Physics, Academy of Science of the Czechoslovakian Republic, Fyzikalni Usstav, for allowing us to use their CrysTbox software for analyzing the electron diffraction patterns.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kumar, S., Sreenivas, K. Effects of dl-alanine fuel and annealing on auto-combustion derived MgFe2O4 powder with low carbon content and improved magnetic properties. Appl. Phys. A 127, 165 (2021). https://doi.org/10.1007/s00339-020-04246-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-020-04246-2