Abstract

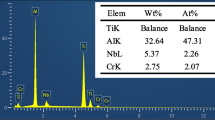

Additive manufacturing and its process involved during manufacturing of engineering components are thriving areas in current researches. The usage of Direct Metal Laser Sintering (DMLS) process, can resolve the difficulties involved in the manufacturing of components used with turbine engines. The commercially available alloy Incone1718 is compatible with DMLS based Su-718 material. This investigation examines and experiments the effect of heat treatment process, using a combination of solutionizing at 1100 °C (2h) and aging at 845 °C for 24h, followed by air cooling. The metallurgical changes were observed with the help of optical imaging, to perceive the phase/structural transformation. Further, the heat treated samples were subjected to electrochemical polarization studies with 1.0 M H2SO4 as an electrolyte. The influence of alloying elements, before and after the heat treatment process of samples were analysed through scanning electron microscope and energy dispersive spectroscopy. The experimental results prove that, corrosion resistance was found to be much better while following the sequence of DMLS HT > Bare DMLS > Bare Commercial > Commercial HT alloy. However, the heat treated DMLS sample obtained during experimentation had lower current density and more positive corrosion potential than the commercial alloys.

Similar content being viewed by others

References

K. Satish Prakash, T. Nancharaih, V. V. Subba Rao, Additive manufacturing techniques in manufacturing—an overview. Mater. Today Proc. 5, 3873–3882 (2018)

Mohsen Mohammadi, W.Rubio, M.Mousseigne, T. Sultan, F. Rezai, Achieving low surface roughness AlSi10Mg 200C parts using direct metal laser sintering. Addit. Manuf. 20, 23–32 (2018)

E. Chlebus, K. Gruber, B. Kuźnicka, J. Kurzac, T. Kurzynowski, Effect of heat treatment on microstructure and mechanical properties of Inconel 718 processed by selective laser melting. Mater. Sci. Eng. A. https:// doi.org/10.1016/ j.msea.2015.05.035

Mohamed Retima, Saida Bouyegh, Hacène Chadli, Effect of the heat treatment on the microstructural evolution of the nickel based Superalloy. Metalurgija-MJoM 17(2), 71–77 (2011)

N. D. Nam, J. G. Kim, Effect of niobium on the corrosion behaviour of low alloy steel in sulfuric acid solution. Corros. Sci. 52, 3377–3384 (2010)

C.A. Huang, T.H. Wang, W.C. Han, C.H. Lee, A study of the galvanic corrosion behavior of Inconel 718 after electron beam welding. Mater Chem Phys 104(2–3), 293–300 (2007)

G. Marchese, E. Bassini, M. Calandri, E. P. Ambrosio, F. Calignano, M. Lorusso, D. Manfredi, M. Pavese, S. Biamino, P. Fino, Microstructural investigation of as-fabricated and heat treated Inconel 625 and Inconel 718 fabricated by direct metal laser sintering, Metal Powder Rep.

N. El-Bagoury, Microstructure and mechanical properties of aged nickel base superalloy. Arch. Appl. Sci. Res. 3(2), 266–276 (2011)

N. El-Bagoury, M.A. Amin, Q. Mohsen, Effect of various heat treatment conditions on microstructure, mechanical properties and corrosion behavior of Ni base superalloys. Int. J. Electrochem. Sci 6, 6718–6732 (2011)

M.A. Khan, Electrochemical polarisation studies on plasma-sprayed nickel-based superalloy. Appl Phys A 120(2), 801–808 (2015)

X. Li, J.J. Shi, C.H. Wang, G.H. Cao, A.M. Russell, Z.J. Zhou, G.F. Chen, Effect of heat treatment on microstructure evolution of Inconel 718 alloy fabricated by selective laser melting. J Alloy Compd 764, 639–649 (2018). https://doi.org/10.1016/j.jallcom.2018.06.112

X. Li, F. Xie, D. Wang, C. Xu, M. Wu, D. Sun, J. Qi, Effect of residual and external stress on corrosion behaviour of X80 pipeline steel in sulphate-reducing bacteria environment. Eng Fail Anal 91, 275–290 (2018). https://doi.org/10.1016/j.engfailanal.2018.04.016

R.R. Sayano, K. Nobe, Electrochemical and corrosion behavior of Fe–Ni alloys in sulfuric acid. Corrosion 25(6), 260–266 (1969)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Raj, B.A., Jappes, J.T.W., Khan, M.A. et al. Studies on heat treatment and electrochemical behaviour of 3D printed DMLS processed nickel-based superalloy. Appl. Phys. A 125, 722 (2019). https://doi.org/10.1007/s00339-019-3019-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-019-3019-5