Abstract

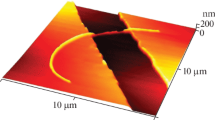

In the growth process of carbon nanotube (CNT) arrays, the height and flatness of the array must be controlled. In general, a profile control algorithm can be used to characterize the morphology of the CNT array through considering the parameters of the profile function as control objective. This paper examines the performance of the present model using real data and finds the defect of losing correlation information in the data. To solve this limitation, the semivariogram borrowed from geostatistics is introduced to add a spatial correlation. Furthermore, we drive the growth height formula based on a physical mechanism and then propose a physical–statistical model that contains a spatial correlation. Simulation and validation are provided to verify the performance of the new model.

Similar content being viewed by others

References

K.L. Jiang, Q.Q. Li, S.S. Fan, Nanotechnology: Spinning continuous carbon nanotube yarns: Carbon nanotubes weave their way into a range of imaginative macroscopic applications. Nature 419(6909), 801–801 (2002)

E.T. Thostenson, Z. Ren, T.-W. Chou, Advances in the science and technology of carbon nanotubes and their composites: a review. Compos. Sci. Technol. 61(13), 1899–1912 (2001)

M. Kumar, Y. Ando, Chemical vapor deposition of carbon nanotubes: A review on growth mechanism and mass production. J. Nanosci. Nanotechnol. 10(6), 3739–3758 (2010)

X. Wang, S. Wu, K.B. Wang, A spatial calibration model for Nanotube film quality prediction. IEEE Trans. Autom. Sci. Eng. 13(2), 903–917 (2016)

C. Feng, K. Liu, J.-S. Wu, L. Liu, J.-S. Cheng, Y. Zhang, Y. Sun, Q. Li, S. Fan, K. Jiang, Flexible, stretchable, transparent conducting films made from superaligned carbon nanotubes. Adv. Funct. Mater. 20(6), 885–891 (2010)

R.S. Wagner, W.C. Ellis, Vapor-liquid mechanism of single crystal growth. Appl. Phys. Lett. 4(5), 89–90 (1964)

E.I. Givargizov, Fundamental aspects of VLS growth. J. Cryst. Growth 31, 20–30 (1975)

J. Rostrup-Nielsen, D.L. Trimm, Mechanisms of carbon formation on nickel-containing catalysts. J. Catal. 48(1), 155–165 (1977)

J. Kong, H.T. Soh, A.M. Cassell, C.F. Quate, H. Dai, Synthesis of individual single-walled carbon nanotubes on patterned silicon wafers. Nature 395(6705), 878–881 (1998)

M. Su, B. Zheng, J. Liu, A scalable CVD method for the synthesis of single-walled carbon nanotubes with high catalyst productivity. Chem. Phys. Lett. 322(5), 321–326 (2000)

J. Kong, A.M. Cassell, H. Dai, Chemical vapor deposition of methane for single-walled carbon nanotubes. Chem. Phys. Lett. 292(4–6), 567–574 (1998)

K. Jiang, C. Feng, K. Liu, S. Fan, A vapor–liquid–solid model for chemical vapor deposition growth of carbon nanotubes. J. Nanosci. Nanotechnol. 7(4), 1494–1504 (2007)

W. Mai, X. Deng, The applications of statistical quantification techniques in nanomechanics and nanoelectronics. Nanotechnology 21(40), 405704 (2010)

T. Dasgupta, B. Weintraub, V.R. Joseph, A physical statistical model for density control of nanowires. IIE Trans. 43(4), 233–241 (2011)

L. Wang, Q. Huang, Cross-domain model building and validation (CDMV): A new modeling strategy to reinforce understanding of nanomanufacturing processes. IEEE Trans. Autom. Sci. Eng. 10(3), 571–578 (2013)

X. Wang, B. Li, K. Wang, S. Wu, An engineering-statistical model for synthesis process of nanomaterials, in 2011 International Conference on Quality, Reliability, Risk, Maintenance, and Safety Engineering (ICQR2MSE) (2011), pp. 72–76

Q. Huang, Physics-driven Bayesian hierarchical modeling of the nanowire growth process at each scale. IIE Trans. 43(1), 1–11 (2010)

L. Xu, Q. Huang, Modeling the interactions among neighboring nanostructures for local feature characterization and defect detection. IEEE Trans. Autom. Sci. Eng. 9(4), 745–754 (2012)

T. Dasgupta, C. Ma, V.R. Joseph, Z.L. Wang, C.F.J. Wu, Statistical modeling and analysis for robust synthesis of nanostructures. J. Am. Stat. Assoc. 103(482), 594–603 (2008)

X. Wang, S. Wu, K. Wang, A run-to-run profile control algorithm for improving the flatness of nano-scale products. IEEE Trans. Autom. Sci. Eng. 12(1), 192–203 (2015)

J. Durbin, G.S. Watson, Testing for serial correlation in least squares regression: I. Biometrika 37(3/4), 409–428 (1950)

O. Schabenberger, C.A. Gotway, Statistical Methods for Spatial Data Analysis (CRC Press, London, 2004)

D.M. Hawkins, N. Cressie, Robust kriginga proposal. J. Int. Assoc. Math. Geol. 16(1), 3–18 (1984)

A.G. Journel, C.J. Huijbregts, Mining Geostatistics (Academic Press, New York, 1978)

N. Cressie, D.M. Hawkins, Robust estimation of the variogram: I. J. Int. Assoc. Math. Geol. 12(2), 115–125 (1980)

O. Danielsson, A. Henry, E. Janzen, Growth rate predictions of chemical vapor deposited silicon carbide epitaxial layers. J. Cryst. Growth 243(1), 170–184 (2002)

N. Cressie, Statistics for Spatical Data (Wiley, New York, 1993)

D. Ginsbourger, D. Dupuy, A. Badea, L. Carraro, O. Roustant, A note on the choice and the estimation of kriging models for the analysis of deterministic computer experiments. Appl. Stoch. Models Bus. Ind. 25(2), 115–131 (2009)

Acknowledgements

The work was supported by the National Natural Science Foundation of China under Grant 71072012, and the Tsinghua University Initiative Scientific Research Program. The authors would like to thank Prof. S. Fan, Dr. L. Liu, and Dr. Q. Cai from Tsinghua-Foxconn Nanotechnology Research Center for providing the raw data and expertise on CNTs array production. They also thank to the National Natural Science Foundation of China.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fan, M., Wu, S. & Xu, C. A physical–statistical model for the growth process of carbon nanotubes. Appl. Phys. A 124, 790 (2018). https://doi.org/10.1007/s00339-018-1916-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-018-1916-7