Abstract

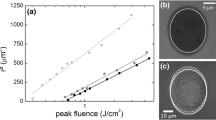

In laser micromachining, the ablation threshold (minimum fluence required to cause ablation) is a key performance parameter and overall indicator of the efficiency of material removal. For pulsed laser micromachining, this important observable depends upon material properties, pulse properties and the number of pulses applied in a complex manner that is not yet well understood. The incubation effect is one example. It manifests as a change in the ablation threshold as a function of number of laser pulses applied and is driven by photoinduced defect accumulation in the material. Here, we study femtosecond (800 nm, 110 fs, 0.1–1 mJ/pulse) micromachining of a material with well-defined initial defect concentrations: doped Si across a range of dopant types and concentrations. The single-pulse ablation threshold (F th,1) was observed to decrease with increasing dopant concentration, from a maximum of 0.70 J/cm2 (±0.02) for undoped Si to 0.51 J/cm2 (±0.01) for highly N-type doped Si. The effect was greater for N-type doped Si than for P-type, consistent with the higher carrier mobility of electrons compared to holes. In contrast, the infinite-pulse ablation threshold (F th,∞ ) was the same for all doping levels and types. We attribute this asymptotic behaviour to a maximum defect concentration that is independent of the initial defect concentration and type. These results lend insight into the mechanism of multipulse, femtosecond laser ablation.

Similar content being viewed by others

References

J. Krüger, W. Kautek, Ultrashort pulse laser interaction with dielectrics and polymers, in Polymers and Light, ed. by T.K. Lippert (Springer, Berlin, 2004), pp. 247–290

E.G. Gamaly, A.V. Rode, Physics of ultra-short laser interaction with matter: from phonon excitation to ultimate transformations. Prog. Quantum Electron. 37(5), 215–323 (2013)

J. Cheng et al., A review of ultrafast laser materials micromachining. Opt. Laser Technol. 46, 88–102 (2013)

M. Meunier et al., Processing of metals and semiconductors by a femtosecond laser-based microfabrication system, in High-Power Lasers and Applications, (International Society for Optics and Photonics, 2003), pp. 169–179

T.H.R. Crawford, A. Borowiec, H.K. Haugen, Femtosecond laser micromachining of grooves in silicon with 800 nm pulses. Appl. Phys. A 80(8), 1717–1724 (2005)

M. Lebugle et al., Guidelines for efficient direct ablation of dielectrics with single femtosecond pulses. Appl. Phys. A 114(1), 129–142 (2014)

N. Sanner et al., Measurement of femtosecond laser-induced damage and ablation thresholds in dielectrics. Appl. Phys. A 94(4), 889–897 (2009)

L. Englert et al., Control of ionization processes in high band gap materials via tailored femtosecond pulses. Opt. Express 15(26), 17855–17862 (2007)

C. Milián et al., Effect of input pulse chirp on nonlinear energy deposition and plasma excitation in water. JOSA B 31(11), 2829–2837 (2014)

D. Ashkenasi et al., Surface damage threshold and structuring of dielectrics using femtosecond laser pulses: the role of incubation. Appl. Surf. Sci. 150(1–4), 101–106 (1999)

B. Stuart et al., Nanosecond-to-femtosecond laser-induced breakdown in dielectrics. Phys. Rev. B 53(4), 1749 (1996)

Z. Sun, M. Lenzner, W. Rudolph, Generic incubation law for laser damage and ablation thresholds. J. Appl. Phys. 117(7), 073102 (2015)

M.D. Perry et al., Ultrashort-pulse laser machining of dielectric materials. J. Appl. Phys. 85(9), 6803–6810 (1999)

M.E. Shaheen, J.E. Gagnon, B.J. Fryer, Femtosecond laser ablation behavior of gold, crystalline silicon, and fused silica: a comparative study. Laser Phys. 24(10), 106102 (2014)

F. Di Niso et al., Role of heat accumulation on the incubation effect in multi-shot laser ablation of stainless steel at high repetition rates. Opt. Express 22(10), 12200–12210 (2014)

A. Schenk, Finite-temperature full random-phase approximation model of band gap narrowing for silicon device simulation. J. Appl. Phys. 84(7), 3684–3695 (1998)

D. Yan, A. Cuevas, Empirical determination of the energy band gap narrowing in highly doped n+ silicon. J. Appl. Phys. 114(4), 044508 (2013)

D. Yan, A. Cuevas, Empirical determination of the energy band gap narrowing in p+ silicon heavily doped with boron. J. Appl. Phys. 116(19), 194505 (2014)

PV Lighthouse (PV Lighthouse Pty. Ltd, 2015), https://www.pvlighthouse.com.au/

M.A. Green, Intrinsic concentration, effective densities of states, and effective mass in silicon. J. Appl. Phys. 67(6), 2944–2954 (1990)

D.B.M. Klaassen, A unified mobility model for device simulation—I. Model equations and concentration dependence. Solid State Electron. 35(7), 953–959 (1992)

D.B.M. Klaassen, A unified mobility model for device simulation—II. Temperature dependence of carrier mobility and lifetime. Solid State Electron. 35(7), 961–967 (1992)

R. Pässler, Dispersion-related description of temperature dependencies of band gaps in semiconductors. Phys. Rev. B 66(8), 085201 (2002)

Q. Cao, J. Fang, Throughput enhancement in femtosecond laser ablation of silicon by N-type doping. In frontiers in optics (Optical Society of America, Tucson, 2014), pp. FW4A–6

J. Fang et al., Doping effects on ablation enhancement in femtosecond laser irradiation of silicon. Appl. Opt. 53(18), 3897–3902 (2014)

R.E. Samad, N.D. Vieira Jr, Geometrical method for determining the surface damage threshold for femtosecond laser pulses. Laser Phys. 16(2), 336–339 (2006)

L.M. Machado et al., D-Scan measurement of ablation threshold incubation effects for ultrashort laser pulses. Opt. Express 20(4), 4114–4123 (2012)

W. de Rossi et al., D-scan measurement of the ablation threshold and incubation parameter of optical materials in the ultrafast regime. Phys. Proced. 39, 642–649 (2012)

R.E. Samad et al., D-scan measurement of the ablation threshold and incubation parameter of optical materials in the ultrafast regime, in Latin America Optics and Photonics Conference (Optical Society of America, Sao Sebastiao, 2012)

O.D. Caulier et al., Femtosecond Laser Pulse Train Interaction with Dielectric Materials (2015). arXiv preprint arXiv:1508.03449

A.Z. Freitas et al., Determination of ablation threshold for composite resins and amalgam irradiated with femtosecond laser pulses. Laser Phys. Lett. 7(3), 236–241 (2010)

R.E. Samad, S.L. Baldochi, J.N.D. Vieira, Diagonal scan measurement of Cr:liSAF 20 ps ablation threshold. Appl. Opt. 47(7), 920–924 (2008)

Incubation—a phenomenon in laser-induced damage of matter (Lenzner Research LLC, 2015), http://www.lenzner.us/incubation/index.html

J. Bonse et al., Femtosecond laser ablation of silicon-modification thresholds and morphology. Appl. Phys. A 74(1), 19–25 (2002)

W. Gao, Z. Li, N.M. Sammes, An Introduction to Electronic Materials for Engineers (World Scientific, Singapore, 2011)

S. Leyder et al., Non-linear absorption of focused femtosecond laser pulses at 1.3 μm inside silicon: independence on doping concentration. Appl. Surf. Sci. 278, 13–18 (2013)

S. Tamulevicius, I. Pozela, J. Jankauskas, Integral stress in ion-implanted silicon. J. Phys. D Appl. Phys. 31(21), 2991 (1998)

A. Vorobyev, C. Guo, Enhanced absorptance of gold following multipulse femtosecond laser ablation. Phys. Rev. Ser. B 72(19), 195422 (2005)

P. Schmid, Optical absorption in heavily doped silicon. Phys. Rev. B 23(10), 5531 (1981)

S. Aw, H. Tan, C. Ong, Optical absorption measurements of band-gap shrinkage in moderately and heavily doped silicon. J. Phys. Condens. Matter 3(42), 8213 (1991)

Acknowledgments

The authors acknowledge financial support from the New Zealand Ministry of Business, Innovation and Employment Grants UOAX1202 (Laser Microfabrication and Micromachining) and UOAX1416 (Tailored Beam Shapes for Fast, Efficient and Precise Femtosecond Laser Micromachining).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Oosterbeek, R.N., Corazza, C., Ashforth, S. et al. Effects of dopant type and concentration on the femtosecond laser ablation threshold and incubation behaviour of silicon. Appl. Phys. A 122, 449 (2016). https://doi.org/10.1007/s00339-016-9969-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-016-9969-y