Abstract

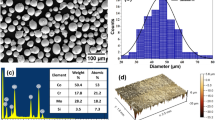

Three kinds of coatings were successfully prepared on Q235 steel by laser cladding technique through adulterating with Mo and nano-Nd2O3 into Ni-based alloys. The effect of Mo and nano-Nd2O3 on the microstructure and properties of Ni-based coatings was investigated systematically by means of optical microscopy, X-ray diffraction, scanning electron microscopy, energy-dispersive spectroscopy, and microhardness testing and wear testing. The results indicated a certain amount of fine grains and polygonal equiaxed grains synthesized after adding Mo and nano-Nd2O3. Both the microhardness and wear resistance of Ni-based coatings improved greatly with a moderate additional amount of Mo and nano-Nd2O3. The largest improvement in microhardness was 31.9 and 14.7 %, and the largest reduction in loss was 45.0 and 30.7 %, respectively, for 5.0 wt% Mo powders and 1.0 wt% nano-Nd2O3. The effect of Mo on microhardness and wear resistance of laser cladding Ni-based alloy coatings is greater than the effect of nano-Nd2O3.

Similar content being viewed by others

References

L. Jiandi, Z. Shuquan, W. Huaming, Microstructure and wear resistance of laser cladding WC particles reinforced composite coatings. Chin. J. Nonferr. Met. 22, 2600–2607 (2012)

H.S. Grewal, H.S. Arora, H. Singh, A. Agrawal, Surface modification of hydroturbine steel using friction stir processing. Appl. Surf. Sci. 268, 547–555 (2013)

E. Chikarakara, S. Naher, D. Brabazon, Process mapping of laser surface modification of AISI 316L stainless steel for biomedical applications. Appl. Phys. A Mater. Sci. Process. 101, 367–371 (2010)

R. Gupta, S. Soni, D.M. Phase, Improvement of oxidation resistance of TiCN films prepared by laser alloying. Appl. Phys. A Mater. Sci. Process. 118, 191–196 (2015)

A. Wiengmoon, J.T.H. Pearce, T. Chairuangsri, Relationship between microstructure, hardness and corrosion resistance in 20 wt% Cr, 27 wt% Cr and 36 wt% Cr high chromium cast irons. Mater. Chem. Phys. 125, 739–748 (2011)

T.E. Abioye, D.G. McCartney, A.T. Clare, Laser cladding of Inconel 625 wire for corrosion protection. J. Mater. Process. Technol. 217, 232–240 (2015)

P. Jakupi, J.J. Noël, D.W. Shoesmith, The evolution of crevice corrosion damage on the Ni–Cr–Mo–W alloy-22 determined by confocal laser scanning microscopy. Corros. Sci. 54, 260–269 (2012)

K. Zhang, W. Liu, X. Shang, Research on the processing experiments of laser metal deposition shaping. Opt. Laser Technol. 39, 549–557 (2007)

Q.-Y. Wang, Y.-F. Zhang, S.-L. Bai, Z.-D. Liu, Microstructures, mechanical properties and corrosion resistance of Hastelloy C22 coating produced by laser cladding. J. Alloys Compd. 553, 253–258 (2013)

H. Zhang, Y. Pan, Y.-Z. He, Synthesis and characterization of FeCoNiCrCu high-entropy alloy coating by laser cladding. Mater. Des. 32, 1910–1915 (2011)

X.-z. Li, Z.-d. Liu, H.-c. Li, Y.-t. Wang, B. Li, Investigations on the behavior of laser cladding Ni–Cr–Mo alloy coating on TP347H stainless steel tube in HCl rich environment. Surf. Coat. Technol. 232, 627–639 (2013)

X. Qiu, Y. Zhang, L. He, C. Liu, Microstructure and corrosion resistance of AlCrFeCuCo high entropy alloy. J. Alloys Compd. 549, 195–199 (2013)

H.M. Wang, H.B. Tang, L.X. Cai, F. Cao, L.Y. Zhang, R.L. Yu, Microstructure and wear properties of laser clad Ti2Ni3Si/Ni3Ti multiphase intermetallic coatings. Appl. Phys. A Mater. Sci. Process. 80, 1677–1682 (2005)

L. Wang, J. Zhoua, Y. Yua, C. Guo, J. Chen, Effect of powders refinement on the tribological behavior of Ni-based composite coatings by laser cladding. Appl. Surf. Sci. 258, 6697–6704 (2012)

T.E. Abioye, D.G. McCartney, A.T. Clare, Laser cladding of Inconel 625 wire for corrosion protection. J. Mater. Process. Technol. 217, 232–240 (2015)

P. Niranatlumpong, H. Koiprasert, The effect of Mo content in plasma-sprayed Mo-NiCrBSi coating on the tribological behavior. Surf. Coat. Technol. 205, 483–489 (2010)

M. Laribi, A.B. Vannes, D. Treheux, Study of mechanical behavior of molybdenum coating using sliding wear and impact tests. Wear 262, 1330–1336 (2007)

L. Mingxi, X. Junjie, Z. Qingyu, H. Yizhu, Effect of Mo content on microstructure and wear resistance of Co-based coatings by laser cladding. Trans. China Weld. Inst. 30, 17–20 (2009)

S.P. Sharma, D.K. Dwivedi, P.K. Jain, Effect of La2O3 addition on the microstructure, hardness and abrasive wear behavior of flame sprayed Ni-based coatings. Wear 267, 853–859 (2009)

L. Mingxi, H. Yizhu, Y. Xiaomin, Effect of nano-Y2O3 on microstructure of laser cladding cobalt-based alloy coatings. Appl. Surf. Sci. 252, 2882–2887 (2006)

D. Lin, J. Hongyun, L. Mingxi, Hardness and wear resistance of laser cladding nano-Sm2O3/Co-based alloy coatings. Spec. Cast. Nonferr. Alloys 33, 805–808 (2013)

P. Farahmand, S. Liu, Z. Zhang, R. Kovacevic, Laser cladding assisted by induction heating of Ni–WC composite enhanced by nano-WC and La2O3. Ceram. Int. 40, 15421–15438 (2014)

C. Zhongqi, Metallography and Heat Treatment (Mechanical Industry Press, Beijing, 1999)

S. Yifu, C. Jizhi, F. Zhongchao, L. Yong, Distribution and behaviour of rare earth in laser coating. J. Chin. Rare Earth Soc. 5, 344–346 (1997)

Y. He, Z. Huang, H. Qi, D. Wang, Z. Li, W. Gao, Oxidation behavior of microcrystalline Ni–20Cr–Y2O3 ODS alloy coatings. Mater. Lett. 45, 79–85 (2000)

J.C. Shin, J.M. Doh, J.K. Yoon, Effect of molybdenum on the microstructure and wear resistance of cobalt-base Stellite hardfacing alloys. Surf. Coat. Technol. 166, 117–126 (2003)

J. Zesheng, Effect of RE-B-Al on composition of permeation layer. J. Chin. Rare Earth Soc. 18, 27–30 (2000)

E. Fernandez, M. Cadenas, R. Gonzalez, Wear behaviour of laser clad NiCrBSi coating. Wear 259, 870–875 (2005)

L. Hengde, X. Jimei, Surface and Interface in Materials (Tsing hua University Press, Beijing, 1990)

Acknowledgments

Authors wish to express thanks to financial support from Excellent Young Talents Foundation Key Project in University of Anhui of China (No. 2013SQRL144ZD).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ding, L., Hu, S., Quan, X. et al. Effect of Mo and nano-Nd2O3 on the microstructure and wear resistance of laser cladding Ni-based alloy coatings. Appl. Phys. A 122, 288 (2016). https://doi.org/10.1007/s00339-016-9905-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-016-9905-1