Abstract

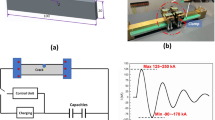

Electropulsing treatment is a practical method to arrest crack propagation. The microstructure characterization and research on the forming mechanism are difficult due to the small affected area (0.01–1 mm2), high-temperature gradient (102 K/mm) and change rate (104–107 K/s). In this paper, the 1045 steel plate with a preexisting crack subjected to high-voltage pulses was investigated. The surface morphologies and microstructure around the crack tip were observed using optical microscopy and scanning electron microscopy. Experimental results showed that the material around the tip melted, splashed and blunted under electropulsing treatment. The microstructure around the molten hole was divided into four distinct regions. An electro-thermal coupled model considering material ejection, cavity formation, current oscillation and temperature-dependent material properties was proposed to investigate the dynamic formation process of molten hole and gradient microstructure. The uneven temperature distribution, high cooling rate and insufficient carbon diffusion led to the formation of gradient microstructure.

Similar content being viewed by others

References

Y.I. Golovin, V.M. Finkel, A.A. Sletkov, Strength Mater. 9, 204 (1977)

A. Amrouche, G. Mesmacque, S. Garcia, A. Talha, Int. J. Fatigue 25, 949 (2003)

T.N. Chakherlou, M. Shakouri, A.B. Aghdam, A. Akbari, Mater. Des. 33, 185 (2012)

Y. Yamashita, T. Kawano, K. Mann, J. Nucl. Sci. Technol. 38, 891 (2001)

A.J. Pinkerton, W. Wang, L. Li, J. Eng. Manuf. 222, 827 (2008)

W. Yanyan, Z. Mingxu, F. Daqing, Fatigue Fract. Eng. Mater. Struct. 16, 363 (1993)

C.S. Shin, C.Q. Cai, Int. J. Fatigue 30, 560 (2008)

J. Yu, H. Zhang, D. Deng, Q. Liu, S. Hao, Int. J. Adv. Manuf. Tech. 1 (2014)

S. Satapathy, F. Stefani, A. Saenz, Electromagn. Launch Tech. 106 (2005)

F. Gallo, S. Satapathy, K. Ravi-Chandar, Electromagn. Launch Tech. 573 (2008)

A. Hosoi, T. Nagahama, Y. Ju, Mater. Sci. Eng. A 533, 38 (2012)

A. Hosoi, T. Yano, Y. Morita, Y. Ju, Fatigue Fract. Eng. Mater. Struct. 37, 1025 (2014)

X.G. Zheng, Y.N. Shi, K. Lu, Mater. Sci. Eng. A 561, 52 (2013)

Y.M. Fu, X.Z. Bai, G.Y. Qiao, Y.D. Hu, J.Y. Luan, Mater. Sci. Technol. 17, 1653 (2001)

G.X. Cai, F.G. Yuan, Int. J. Fract. 96, 279 (1999)

T.J.C. Liu, Eng. Fract. Mech. 78, 666 (2011)

F. Gallo, S. Satapathy, K. Ravi-Chandar, Int. J. Fract. 167, 183 (2011)

S. Hui, Z. Wang, X. He, T. Nonferr, Metal. Soc. 23, 32 (2013)

Y. Zhou, J. Guo, M. Gao, G. He, Mater. Lett. 58, 1732 (2004)

H. Conrad, Mater. Sci. Eng. A 282, 227 (2000)

Acknowledgments

This work was financially supported by the National Basic Research Program of China (973 Program) (No. 2011CB013404). The authors are grateful to State Key Laboratory of Tribology and Pro. Shengzhi Hao from Dalian University of Technology for facility support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wei, S., Wang, G., Deng, D. et al. Microstructure characterization and thermal behavior around crack tip under electropulsing. Appl. Phys. A 121, 69–76 (2015). https://doi.org/10.1007/s00339-015-9383-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00339-015-9383-x