Abstract

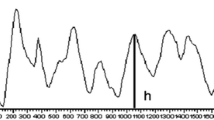

This paper has investigated the dynamic behavior of a cylindrically shaped DNA nanoparticle during its displacement on a rough substrate by an atomic force microscope. Due to the cylindrical geometry of the DNA nanoparticle, two multi-asperity models have been considered for the adhesion between nanoparticle and rough substrate. The two selected models for the contact between smooth and rough surfaces have been further developed for cylindrical geometries. One of these models is analytical and based on uniform asperities and the other one is based on random asperities. Also, in each of these models, the real area of contact between particle and rough substrate has been calculated based on the number of asperities in contact. Then, a 3D dynamic model for the manipulation of cylindrical nanoparticle on rough substrate has been developed and simulated. The maximum difference between the results obtained from the two multi-asperity models is <5 %, indicating a good agreement between the two models. The comparison of critical forces indicates that the critical force necessary for moving a particle is smaller for rough substrates than for smooth substrates and larger compared to the critical force obtained from the Rabinovich model, which is single-asperity model. Finally, the surface roughness parameters were estimated from the topographic images, and the manipulation process was simulated for these substrates by developing the relevant equations. The obtained results indicated that the critical force for a substrate with a higher root-mean-square roughness is smaller and particles can be moved easier on such a substrate.

Similar content being viewed by others

References

M. Sitti, H. Hashimoto, Controlled pushing of nanoparticles: modeling and experiments. IEEE/ASME Trans. Mechatron. 5(2), 199–211 (2000)

Y.I. Rabinovich, J.J. Adler, A. Ata, R.K. Singh, B.M. Moudgil, Adhesion between nanoscale rough surfaces: I. Role of asperity geometry. J. Colloid Interface Sci. 232(1), 10–16 (2000)

P. Prokopovich, V. Starov, Adhesion models: from single to multiple asperity contacts. Adv. Colloid Interface Sci. 168(1), 210–222 (2011)

D. Pathak, T. Wagner, J. Šubrt, J. Kupcik, Characterization of mechanically synthesized AgInSe2 nanostructures 1. Can. J. Phys. 92(7/8), 789–796 (2014)

D. Pathak, R.K. Bedi, D. Kaur, R. Kumar, 200 MeV Ag+ Ion beam induced modifications in AgInSe2 films deposited by hot wall vaccum evaporation method. Chalcogenide Lett. 8(1), 213–222 (2011)

K.N.G. Fuller, D.F.R.S. Tabor. The effect of surface roughness on the adhesion of elastic solids. In: Proceedings of the Royal Society of London A: Mathematical, Physical and Engineering Sciences, vol. 345. No. 1642 (The Royal Society, 1975)

H. Rumpf, Particle Technology, vol. 116 (Chapman and Hall, London, 1990)

Y.I. Rabinovich, J.J. Adler, A. Ata, R.K. Singh, B.M. Moudgil, Adhesion between nanoscale rough surfaces: II. Measurement and comparison with theory. J. Colloid Interface Sci. 232(1), 17–24 (2000)

M. Kolahdoozan, M. Hamedi, M. Nikkhah-Bahrami, A novel model for the effect of geometric properties of micro/nanoscale asperities on surface adhesion. Int. J. Adhes. Adhes. 48, 280–287 (2014)

J. Katainen, M. Paajanen, E. Ahtola, V. Pore, J. Lahtinen, Adhesion as an interplay between particle size and surface roughness. J. Colloid Interface Sci. 304(2), 524–529 (2006)

D. Pathak, R.K. Bedi, D. Kaur, Effect of substrate temperature on the structural, optical, and electrical properties of silver-indium-selenide films prepared by using laser ablation. J. Korean Phys. Soc. 56(3), 836–841 (2010)

B.N.J. Persson, Adhesion between an elastic body and a randomly rough hard surface. Eur. Phys. J. E 8(4), 385–401 (2002)

S. Patra, S.M. Ali, P. Sahoo, Elastic–plastic adhesive contact of rough surfaces with asymmetric distribution of asperity heights. Wear 265(3), 554–559 (2008)

S. Ţălu, S. Stach, A. Mahajan, D. Pathak, T. Wagner, A. Kumar, R.K. Bedi, M. Ţălu, Multifractal characterization of water soluble copper phthalocyanine based films surfaces. Electron. Mater. Lett. 10(4), 719–730 (2014)

S. You, M.P. Wan, Mathematical models for the van der Waals force and capillary force between a rough particle and surface. Langmuir 29(29), 9104–9117 (2013)

P. Prokopovich, S. Perni, Multiasperity contact adhesion model for universal asperity height and radius of curvature distributions. Langmuir 26(22), 17028–17036 (2010)

M.H. Korayem, M. Zakeri, Dynamic modeling of manipulation of micro/nanoparticles on rough surfaces. Appl. Surf. Sci. 257(15), 6503–6513 (2011)

M.H. Korayem, H. Badkoobeh Hezaveh, M. Taheri, Dynamic modeling and simulation of rough cylindrical micro/nanoparticle manipulation with atomic force microscopy. Microsc. Microanal. 20(06), 1692–1707 (2014)

A. Tafazzoli, M. Sitti. Dynamic behavior and simulation of nanoparticle sliding during nanoprobe-based positioning. In: LASME 2004 International Mechanical Engineering Congress and Exposition (American Society of Mechanical Engineers, 2004)

M.H. Korayem, Z. Mahmoodi, M. Taheri, M.B. Saraee. Three-dimensional modeling and simulation of the AFM-based manipulation of spherical biological micro/nanoparticles with the consideration of contact mechanics theories. Proc. Inst. Mech. Eng. Part K J. Multi-body Dyn. 1464419314567551 (2015)

S. Yang, H. Zhang, S.M. Hsu, Correction of random surface roughness on colloidal probes in measuring adhesion. Langmuir 23(3), 1195–1202 (2007)

Y.P. Zhao, L.S. Wang, T.X. Yu, Mechanics of adhesion in MEMS—a review. J. Adhes. Sci. Technol. 17(4), 519–546 (2003)

B. Bhushan, Z. Burton, Adhesion and friction properties of polymers in microfluidic devices. Nanotechnology 16(4), 467 (2005)

K.L. Johnson, K. Kendall, A.D. Roberts. Surface energy and the contact of elastic solids. In: Proceedings of the Royal Society of London A: Mathematical, Physical and Engineering Sciences, Vol. 324. No. 1558 (The Royal Society, 1971)

B.V. Derjaguin, V.M. Muller, Y.P. Toporov, Effect of contact deformations on the adhesion of particles. J. Colloid Interface Sci. 53(2), 314–326 (1975)

M. Barquins, Adherence and rolling kinetics of a rigid cylinder in contact with a natural rubber surface. J. Adhes. 26(1), 1–12 (1988)

F. Jin, X. Guo, Non-slipping adhesive contact of a rigid cylinder on an elastic power-law graded half-space. Int. J. Solids Struct. 47(11), 1508–1521 (2010)

K.L. Johnson, Contact mechanics (Cambridge University Press, Cambridge, 1985)

M. Ruths, J.N. Israelachvili, Surface forces and nanorheology of molecularly thin films, in Nanotribology and Nanomechanics II (Springer, Berlin, Heidelberg, 2011), pp. 107–202

U.D. Schwarz, A generalized analytical model for the elastic deformation of an adhesive contact between a sphere and a flat surface. J. Colloid Interface Sci. 261(1), 99–106 (2003)

S. Kuhn, P. Rahe, Discriminating short-range from van der Waals forces using total force data in noncontact atomic force microscopy. Phys. Rev. B 89(23), 235417 (2014)

M.H. Korayem, M. Zakeri, Sensitivity analysis of nanoparticles pushing critical conditions in 2-D controlled nanomanipulation based on AFM. Int. J. Adv. Manuf. Technol. 41(7–8), 714–726 (2009)

Acknowledgments

The authors of this paper wish to thank the Mahar Fan Abzar Company for providing the topographic images of a silica substrate.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Korayem, M.H., Mirmohammad, S.A. & Saraee, M.B. Investigating the effect of surface roughness on the critical sliding and rolling forces of cylindrical nanoparticles based on the multi-asperity contact models. Appl. Phys. A 120, 1511–1528 (2015). https://doi.org/10.1007/s00339-015-9348-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00339-015-9348-0