Abstract

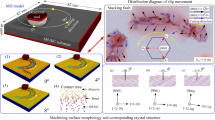

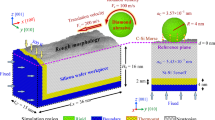

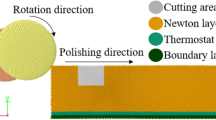

During the final stages of polishing silicon wafers, much of the interactions between silicon and diamond abrasive takes place at the silicon asperities. These interactions, leading to material removal, were investigated in a MD simulation of polishing of a silicon wafer with a diamond abrasive under dry conditions. Simulations were conducted with silicon asperities of different geometries, different abrasive configurations, and polishing speeds. Under the conditions of polishing, the silicon atoms from the asperities were found to bond chemically to the surface of the diamond abrasive. Continued transverse motion of the diamond abrasive (relative to the silicon asperity) leads to tensile pulling, necking, and ultimate separation of the silicon asperity material instead of conventional material removal in polishing (chip formation) involving cutting/ploughing, which takes place in the absence of chemical bonding between the abrasive and the asperity material. This phenomenon has not been reported previously in the literature. The thrust and cutting forces initially increase due to the increase in the number of asperity atoms affected finally reaching a maximum. This is followed by a decrease of these forces due to tensile pulling and formation of individual strings followed by ultimate separation or breakage of the final string. The ratio of thrust force (F z ) to the cutting force (F x ), i.e. |(F z /F x )| was found to increase continuously to a maximum of ∼0.8 followed by continuous decrease to ∼0.25. This is in contrast to a more or less constant value of ∼2 in the case of tools with rounded radii or tools with large negative rake angles, where material is removed in the form of chips ahead of the tool. Three regions of the asperity have been identified that are useful in the development of a phenomenological model for polishing that enables computation of material removal rates: (1) the region directly in front of the abrasive for which the probability of the removal of an asperity atom is close to unity, (2) the distant region where this probability is nearly zero, and (3) an intermediate region from which the probability of removal is close to half.

Similar content being viewed by others

References

W.-C. Lih, S.T.S. Bukkapatnam, P. Rao, N. Chandrasekaran, R. Komanduri, IEEE Trans. Autom. Sci. Eng. 5(1), 71–83 (2008)

P.B. Zantye, A. Kumar, A.K. Sikder, Mater. Sci. Eng. R45, 89–220 (2004)

Y. Ye, R. Biswas, A. Bastawros, A. Chandra, Appl. Phys. Lett. 81, 1875–1877 (2002)

J. Zhong, J.B. Adams, L.G. Hector Jr., J. Appl. Phys. 94, 4306–4314 (2003)

E. Chagarov, J.B. Adams, J. Appl. Phys. 94, 3853–3861 (2003)

A. Rajendran, Y. Takahashi, M. Koyama, M. Kubo, A. Miyamoto, Appl. Surf. Sci. 244, 34–38 (2005)

T. Yokosuka, H. Kurokawa, S. Takami, M. Kubo, A. Miyamoto, A. Imamura, Jpn. J. Appl. Phys., Part 1 41, 2410–2413 (2002)

T. Yokosuka, K. Sasata, H. Kurokawa, S. Takami, M. Kubo, A. Imamura, A. Miyamoto, Jpn. J. Appl. Phys., Part 1 42, 1897–1902 (2003)

R. Zhang, X. Wang, P. Shrotriya, R. Biswas, A. Bastawros, A. Chandra, Mach. Sci. Technol. 11, 515–530 (2007)

X. Han, Appl. Surf. Sci. 253, 6211–6216 (2007)

N. Chandrasekaran, A. Noori-Khajavi, L.M. Raff, R. Komanduri, Philos. Mag. 77, 7–26 (1997)

R. Komanduri, N. Chandrasekaran, L.M. Raff, Wear 218, 84–97 (1998)

R. Komanduri, N. Chandrasekaran, L.M. Raff, Ann. CIRP 48(1), 67–72 (1999)

R. Komanduri, N. Chandrasekaran, L.M. Raff, Philos. Mag. B 79, 955–968 (1999)

R. Komanduri, N. Chandrasekaran, L.M. Raff, Phys. Rev. B 61, 14007 (2000)

R. Komanduri, N. Chandrasekaran, L.M. Raff, Wear 242, 60–88 (2000)

R. Komanduri, L.M. Raff, Proc. Inst. Mech. Eng. (Lond.), J. Eng. Manuf. 215, 1639–1672 (2001). Part B

R. Komanduri, N. Chandrasekaran, L.M. Raff, Philos. Mag. B 81, 1989–2019 (2001)

R. Komanduri, N. Chandrasekaran, L.M. Raff, Wear 240, 113–143 (2000)

P. Masini, M. Bernasconi, J. Phys.: Condens. Matter 14, 4133–4144 (2002)

D.A. Litton, S.H. Garofalini, J. Appl. Phys. 89, 6013–6023 (2001)

E.B. Webb III, S.H. Garofalini, J. Non-Crystal. Solids 226, 47–57 (1998)

Y. Li, Microelectronic Applications of Chemical Mechanical Planarization (Wiley, New York, 2007)

H. Liang, D.R. Craven, Tribology in Chemical Mechanical Planarization (CRC Press, Boca Raton, 2005)

M.R. Oliver, Chemical Mechanical Planarization of Semiconductor Materials (Springer, Berlin, 2004)

D.K. Watts, N. Kimura, M. Tsujimura, New Trends Electrochem. Technol. 3, 437–469 (2005)

H. Liang, Tribol. Int. 38, 235–242 (2005)

R.K. Singh, MRS Bull. 27, 743–747 (2002)

U. Landman, W.D. Luedtke, E.M. Ringer, Wear 153, 3 (1992)

R. Komanduri, Ann. CIRP 45(1), 509–514 (1996)

R. Komanduri, Int. J. Mach. Tool Des. Res. 11, 223–233 (1971)

T.N. Loladze, G.V. Bakuchava, in Proc. Int. Grinding Conference, Pittsburgh, PA, ed. by M.C. Shaw (Carnegie Press, Pittsburgh, 1972), pp. 432–448

R. Komanduri, M.C. Shaw, Nature 255, 211 (1975)

R. Komanduri, M.C. Shaw, Philos. Mag. 34, 195–204 (1976)

R. Narulkar, S. Bukkapatnam, L.M. Raff, R. Komanduri, Philos. Mag. 88, 1259–1275 (2008)

S.R. Bhagavatula, R. Komanduri, Philos. Mag. A 74, 1003–1017 (1996)

M. Jiang, N.O. Wood, R. Komanduri, Trans. ASME, J. Eng. Mater. Technol. 120, 304–312 (1998)

J. Yan, M. Yoshino, T. Kuriagawa, T. Shirakashi, K. Syoji, R. Komanduri, Mater. Sci. Eng. B 297(1–2), 230–234 (2000)

Y. Zhao, L. Chang, S.H. Kim, Wear 254, 332–339 (2003)

P.M. Agrawal, L.M. Raff, R. Komanduri, Phys. Rev. B 72, 125206 (2005)

J. Tersoff, Phys. Rev. B 39, 5566–5568 (1989)

S.J. Cook, P. Clancy, Phys. Rev. B 47, 7686–7699 (1993)

S. Yoo, X.C. Zeng, J.R. Morris, J. Chem. Phys. 120, 1654–1656 (2004)

M.P. Allen, D.J. Tildesley, Computer Simulation of Liquids (Oxford Science Publications, Oxford, 1993)

P.M. Agrawal, L.M. Raff, S. Bukkapatnam, R. Komanduri, Tribol. Int. 43, 100–107 (2010)

H.W. Yeom, S. Takeda, E. Rotenberg, I. Matsuda, K. Horikoshi, J. Schaefer, C.M. Lee, S.D. Kevan, T. Ohta, T. Nagao, S. Hasegawa, Phys. Rev. Lett. 82, 4898–4901 (1999)

Y. Mo, I. Szlufarska, Appl. Phys. Lett. 90, 181926 (2007)

A. Mattoni, M. Ippolito, L. Colombo, Phys. Rev. B 76, 224103 (2007)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Agrawal, P.M., Raff, L.M., Bukkapatnam, S. et al. Molecular dynamics investigations on polishing of a silicon wafer with a diamond abrasive. Appl. Phys. A 100, 89–104 (2010). https://doi.org/10.1007/s00339-010-5570-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00339-010-5570-y