Abstract

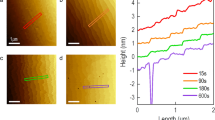

In-situ X-ray diffraction (XRD) was employed to study the effect of the deliberate change of the Ti/Ni ratio during the deposition of Ni-Ti films. Thus, graded films were deposited exhibiting distinctive composition and crystalline structure along the growth direction. The as-sputtered films were ex-situ characterized by Auger electron spectroscopy (AES), cross-sectional transmission electron microscopy (XTEM), and electrical resistivity (ER) measurements (during thermal cycling). In this paper results are presented concerning a film (thickness of ≈ 420 nm) with a Ti-rich composition in the central part (ranging from 50 to ≈60 at. %) and near-equiatomic composition in the extremities, following four distinct deposition periods (different Ti target powers). During the initial deposition step (near-equiatomic composition) the Ni-Ti B2 phase starts by stacking onto (h00) planes on the naturally oxidized Si(100) substrate due to the presence of the native Si oxide (2–3 nm). The increase of the power of the Ti target in the second and third steps induced the precipitation of Ti2Ni. When stopping the Ti co-sputtering, Ti2Ni dissolves and, thus, plays the role of a Ti reservoir for the formation of B2 phase now preferentially stacking onto (110) with the system approaching again the equiatomic composition. The ex-situ study of the morphology of the interface has shown the presence of NiSi2 silicides (A-NiSi2 and B-NiSi2), Ti4Ni4Si7, Ti2Ni and a non-identified phase constituted by Ni, Ti and Si, most likely amorphous. During thermal cycling, ER measurements revealed phase transitions associated with the B2, R-phase and B19′ phases. These type of studies allow the identification of intermediate states during deposition and annealing, and the correlation with the final structure of the film, being useful for the optimisation of the deposition parameters in order to fabricate films with a two-way reversible actuation.

Similar content being viewed by others

References

K. Otsuka, T. Kakeshita, MRS Bull. 27, 91 (2002)

K. Otsuka, X. Ren, Prog. Mater. Sci. 50, 511 (2005)

R.H. Wolf, A.H. Heuer, J. Microelectromech. Syst. 4, 206 (1995)

P. Krulevitch, A.P. Lee, P.B. Ramsey, J.C. Trevino, J. Hamilton, M.A. Northrup, J. Microelectromech. Syst. 5, 270 (1996)

H. Kahn, M.A. Huff, A.H. Heuer, J. Micromech. Microeng. 8, 213 (1998)

Y. Fu, H. Du, W. Huang, S. Zhang, M. Hu, Sens. Actuators A 112, 395 (2004)

M. Bendahan, K. Aguir, J.L. Seguin, H. Carchano, Sens. Actuators 74, 242 (1999)

J.A. Walker, K.J. Gabriel, M. Mehregany, Sens. Actuators A 21–23, 243 (1990)

J.D. Busch, A.D. Johnson, C.H. Lee, D.A. Stevenson, J. Appl. Phys. 68, 6224 (1990)

A.P. Jardine, H. Zhang, L.D. Wasielesky, Mater. Res. Soc. Symp. Proc. 187, 181 (1990)

J.D. Johnson, J. Micromech. Microeng. 1, 34 (1991)

A.P. Jardine, J. Vac. Sci. Technol. A 13, 1058 (1995)

A. Ishida, V. Martynov, MRS Bull. 27, 111 (2002)

B. Winzek, S. Schmitz, H. Rumpf, T. Sterzl, R. Hassdorf, S. Thienhaus, J. Feydt, M. Moske, E. Quandt, Mater. Sci. Eng. A 378, 40 (2004)

K.K. Ho, K.P. Mohanchandra, G.P. Carman, Thin Solid Films 413, 1 (2002)

C.-L. Shih, B.-K. Lai, H. Kahn, S.M. Phillips, A.H. Heuer, J. Microelectromech. Syst. 10, 69 (2001)

S. Miyazaki, A. Ishida, Mater. Sci. Eng. A 273–275, 106 (1999)

R.M.S. Martins, N. Schell, R.J.C. Silva, L. Pereira, K.K. Mahesh, F.M.B. Fernandes, Sens. Actuators B 126, 332 (2007)

A. Ohta, S. Bhansali, I. Kishimoto, A. Umeda, Sens. Actuators A 86, 165 (2000)

S. Sanjabi, Y.Z. Cao, S.K. Sadrnezhaad, Z.H. Barber, J. Vac. Sci. Technol. A 23, 1425 (2005)

K.K. Ho, G.P. Carman, Thin Solid Films 370, 18 (2000)

D. Shindo, Y. Murakami, T. Ohba, MRS Bull. 27, 121 (2002)

H. Sitepu, W.W. Schmahl, D.M. Toebbens, Textures Microstruct. 35, 185 (2003)

T. Goryczka, H. Morawiec, J. Alloys Compd. 367, 137 (2004)

J. Khalil-Allafi, W.W. Schmahl, D.M. Toebbens, Acta Mater. 54, 3171 (2006)

P. Šittner, M. Landa, P. Lukáš, V. Novák, Mech. Mater. 38, 475 (2006)

J.-M. Ting, P. Chen, J. Vac. Sci. Technol. A 19, 2382 (2001)

J.Z. Chen, S.K. Wu, J. Non-Cryst. Solids 288, 159 (2001)

H.-J. Lee, H. Ni, D.T. Wu, A.G. Ramirez, Appl. Phys. Lett. 87, 114102-1 (2005)

H.-J. Lee, H. Ni, D.T. Wu, A.G. Ramirez, Appl. Phys. Lett. 87, 124102 (2005)

R.M.S. Martins, F.M.B. Fernandes, R.J.C. Silva, L. Pereira, P.R. Gordo, M.J.P. Maneira, M. Beckers, A. Mücklich, N. Schell, Appl. Phys. A 83, 139 (2006)

I.-J. Kim, H. Nanjo, T. Iijima, T. Abe, Japan. J. Appl. Phys. 39, 568 (2000)

R.M.S. Martins, N. Schell, M. Beckers, R.J.C. Silva, K.K. Mahesh, F.M.B. Fernandes, Mater. Sci. Eng. A, DOI:10.1016/j.msea.2006.12.225 (2007)

Y.S. Liu, D. Xu, B.H. Jiang, Z.Y. Yuan, P. van Houtte, J. Micromech. Microeng. 15, 575 (2005)

K.R.C. Gisser, J.D. Busch, A.D. Johnson, A.B. Ellis, Appl. Phys. Lett. 61, 1632 (1992)

R.M.S. Martins, N. Schell, M. Beckers, K.K. Mahesh, R.J.C. Silva, F.M.B. Fernandes, Appl. Phys. A 84, 285 (2006)

W. Matz, N. Schell, W. Neumann, J. Bøttiger, J. Chevallier, Rev. Sci. Instrum. 72, 3344 (2001)

W. Matz, N. Schell, G. Bernhard, F. Prokert, T. Reich, J. Claußner, W. Oehme, R. Schlenk, S. Dienel, H. Funke, F. Eichhorn, M. Betzl, D. Pröhl, U. Strauch, G. Hüttig, H. Krug, W. Neumann, V. Brendler, P. Reichel, M.A. Denecke, H. Nitsche, J. Synchroton Radiat. 6, 1076 (1999)

P. Surbled, C. Clerc, B.L. Pioufle, M. Ataka, H. Fujita, Thin Solid Films 401, 52 (2001)

A.S. Paula, J.H.P.G. Canejo, K.K. Mahesh, R.J.C. Silva, F.M.B. Fernandes, R.M.S. Martins, A.M.A. Cardoso, N. Schell, Nucl. Instrum. Methods B 246, 206 (2006)

M.J. Vestel, D.S. Grummon, Mater. Sci. Eng. A 378, 437 (2004)

J.X. Zhang, M. Sato, A. Ishida, Acta Mater. 51, 3121 (2003)

N. Schell, R.M.S. Martins, F.M.B. Fernandes, Appl. Phys. A 81, 1441 (2005)

S. Stemmer, G. Duscher, C. Scheu, A.H. Heuer, M. Rühle, J. Mater. Res. 12, 1734 (1997)

S.K. Wu, J.Z. Chen, Y.J. Wu, J.Y. Wang, M.N. Yu, F.R. Chen, J.J. Kai, Philos. Mag. A 81, 1939 (2001)

D. Wan, K. Komvopoulos, J. Mater. Res. 20, 1606 (2005)

A. Steegen, K. Maex, Mater. Sci. Eng. R 38, 1 (2002)

C.J. Tsai, K.H. Yu, Thin Solid Films 350, 91 (1999)

D.S. Grummon, J. Zhang, Phys. Stat. Solidi A 186, 17 (2001)

J.-M. Zhang, F. Ma, K.-W. Xu, Surf. Interf. Anal. 35, 662 (2003)

A. Ishida, K. Ogawa, M. Sato, S. Miyazaki, Metall. Mater. Trans. A 28, A1985 (1997)

U. Falke, F. Fenske, S. Schulze, M. Hietschold, Phys. Stat. Solidi A 162, 615 (1997)

E. Horache, J. Van Der Spiegel, J.E. Fischer, Thin Solid Films 177, 263 (1989)

T.-H. Nam, J.-H. Kim, M.-S. Choi, H.-W. Lee, Y.-W. Kim, J. Phys. IV 112, 893 (2003)

A.D. Johnson, M. Fanucchi, V. Gupta, V. Martynov, V. Galhotra, K. Clements, “TiNi as a nano-actuator, experimental verification of excitation by electron-beam heating” (2003); http://www.innovation-on-demand.com/Papers/Nanoactuation_Paper.htm

Q. Su, S.Z. Hua, M. Wuttig, J. Alloys Compd. 211/212, 460 (1994)

Y.Q. Fu, S. Zhang, M.J. Wu, W.M. Huang, H.J. Du, J.K. Luo, A.J. Flewitt, W.I. Milne, Thin Solid Films 515, 80 (2006)

Author information

Authors and Affiliations

Corresponding author

Additional information

PACS

81.15.Cd; 61.10.Nz; 68.55.Jk

Rights and permissions

About this article

Cite this article

Martins, R., Schell, N., Mücklich, A. et al. Study of graded Ni-Ti shape memory alloy film growth on Si(100) substrate. Appl. Phys. A 91, 291–299 (2008). https://doi.org/10.1007/s00339-008-4397-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00339-008-4397-2