Abstract

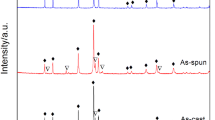

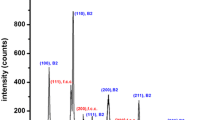

In this study, we carried out a systematic investigation of the microstructures of (Fe0.88Co0.12)82La7Si11 prepared by arc melting/melt spinning and subsequent annealing. The arc-melted sample contains 36 wt. % of the desired La(Fe,Co,Si)13 phase (denoted by 1:13 in the following). Annealing of the arc-melted ingot at 1273 K for 200 h leads to a single 1:13 phase. Melt spinning enhances formation of the 1:13 phase. As the wheel speed reaches or is greater than 15 m/s, over 50 wt. % of 1:13 is directly formed in the melt-spun ribbons. A subsequent annealing of these melt-spun samples at 1273 K for 20 min results in a nearly single phase 1:13 structure. The samples prepared under different conditions were systematically studied by transmission electron microscopy in order to elucidate possible origins of the enhanced formation of the 1:13 phase when using the new technique. The presence of a high density of La-Fe-Co-Si clusters in the undercooled liquid is believed to contribute to the formation of the 1:13 phase in melt-spun ribbons. The enhanced atomic diffusivity as a result of structural refinement in melt-spun samples accounts for the subsequent fast transformation of the 1:13 phase during the annealing process.

Similar content being viewed by others

References

Gschneidner Jr KA, Pecharsky VK (2000) Annu Rev Mater Sci 30:387

Huang MQ, Wallace WE, McHenry ME, Chen Q, Ma BM (2004) J Appl Phys 83:6471

Irisawa K, Fujita A, Fukamichi K, Mitamura H, Goto T (2001) J Alloys Compd 327:17

Hu FX, Shen BG, Sun JR, Cheng ZH, Rao GH, Zhang XX (2001) Appl Phys Lett 78:3675

Hu FX, Shen BG, Sun JR, Cheng ZH, Zhang XX (2000) J Phys Condens Matter 12:L691

Rao GH, Liang JK, Zhang YL, Tang WH, Cheng XR (1996) J Appl Phys 80:336

Liu XB, Altounian Z (2003) J Magn Magn Mater 264:209

Liu XB, Altounian Z, Beath AD (2004) J Appl Phys 95:7067

Croat JJ, Herbst JF, Lee RW, Pinkerton FE (1984) J Appl Phys 55:2078

Liu XB, Altounian Z, Tu GH (2004) J Phys Condens Matter 16:8043

Yan A, Muller KH, Gutfleisch O (2005) J Appl Phys 97:036102

Boswell PG, Chadwick GA (1977) Scr Metall 11:459

Mutschele T, Kirchneim R (1987) Scr Metall 21:1101

Gleiter H (1989) Prog Mater Sci 33:223

Author information

Authors and Affiliations

Corresponding author

Additional information

PACS

71.20.Eh; 81.07.Bc; 68.37.Lp

Rights and permissions

About this article

Cite this article

Liu, X., Liu, X., Altounian, Z. et al. Microstructures of (Fe0.88Co0.12)82La7Si11 prepared by arc-melting/melt spinning and subsequent annealing. Appl. Phys. A 82, 339–343 (2006). https://doi.org/10.1007/s00339-005-3328-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00339-005-3328-8