Abstract

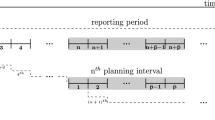

Modern advanced planning systems offer the technical prerequisites for an allocation of “available-to-promise” (ATP) quantities—i.e. not yet reserved stock and planned production quantities—to different customer segments and for a real time promising of incoming customer orders (ATP consumption) respecting allocated quota. The basic idea of ATP allocation is to increase revenues by means of customer segmentation, as it has successfully been practiced in the airline industry. However, as far as manufacturing industries and make-to-stock production are concerned, it is unclear, whether, when, why and how much benefits actually arise. Using practical data of the lighting industry as an example, this paper reveals such potential benefits. Furthermore, it shows how the current practice of rule-based allocation and consumption can be improved by means of up-to-date demand information and changed customer segmentation. Deterministic linear programming models for ATP allocation and ATP consumption are proposed. Their application is tested in simulation runs using the lighting data. The results are compared with conventional real time order promising with(out) customer segmentation and with batch assignment of customer orders. This research shows that—also in make-to-stock manufacturing industries—customer segmentation can indeed improve profits substantially if customer heterogeneity is high enough and reliable information about ATP supply and customer demand is available. Surprisingly, the choice of an appropriate number of priority classes appears more important than the selection of the ATP consumption policy or the clustering method to be applied.

Similar content being viewed by others

References

Ahuja R, Magnanti T, Orlin J (1993) Network flows: theory, algorithms and applications. Prentice Hall, Englewood Cliffs

Ball M, Chen C-Y, Zhao Z-Y (2004) Available to promise. In: Simchi-Levi D, Wu S, Shen Z-J(eds) Handbook of quantitative supply chain management: modelling in the eBusiness era. Kluwer, Boston, pp 447–482

Chen C-Y, Zhao Z-Y, Ball M (2001) Quantity and due date quoting available to promise. Inform Syst Frontiers 3(4): 477–488

Chen C-Y, Zhao Z-Y, Ball M (2002) A model for batch advanced available–to–promise. Product Oper Manage 11(4): 424–440

de Vericourt F, Karaesmen F, Dallery Y (2002) Optimal stock allocation for a capacitated supply system. Manage Sci 48(11): 1486–1501

Dickersbach J (2004) Supply chain management with APO. Springer, Berlin

Fischer M (2001) Available-to-Promise: Aufgaben und Verfahren im Rahmen des Supply Chain Management. S. Roderer Verlag, Regensburg

Fleischmann B, Meyr H (2003a) Customer orientation in Advanced Planning Systems. In: Dyckhoff H, Lackes R, Reese J(eds) Supply Chain Management and Reverse Logistics. Springer, Berlin, pp 297–321

Fleischmann B, Meyr H (2003b) Planning hierarchy, modeling and Advanced Planning Systems. In: de Kok A, Graves S(eds) Supply chain management: design, coordination, operation, Vol 11 of handbooks in operations research and management science. Elsevier, Amsterdam, pp 457–523

ILOG (2007) ILOG OPL development studio. URL: http://www.ilog.com/pro ducts/oplstudio/

Keskinocak P, Tayur S (2004) Due-date management policies. In: Simchi-Levi D, Wu SD, Shen Z-J(eds) Handbook of quantitative supply chain Analysis – Modeling in the E-Business era. Chap 12. Kluwer, Dordrecht, pp 485–547

Kilger C, Meyr H (2008) Demand fulfilment and ATP. In: Stadtler H, Kilger C(eds) Supply Chain Management and Advanced Planning 4th edn, Chap 9. Springer, Berlin, pp 181–198

Kilger C, Wetterauer U (2008) The selection process. In: Stadtler H, Kilger C(eds) Supply Chain Management and Advanced Planning 4th edn, Chap 16. Springer, Berlin, pp 309–323

Knolmayer G, Mertens P, Zeier A (2002) Supply Chain Management based on SAP Systems. Springer, Berlin

Lee H, Padmanabhan V, Whang S (1997) The bullwhip effect in supply chains. Sloan Manage Rev Spring 1997: 93–102

Meyr H (2007) Clustering methods for rationing limited resources. Schriften zur Quantitativen Betriebswirtschaftslehre 4/2007, Technische Universitaet Darmstadt, Hochschulstr. 1, 64289 Darmstadt, Germany

Meyr H, Rosič H, Seipl C, Wagner M, Wetterauer U (2008) Architecture of selected APS. In: Stadtler H, Kilger C(eds) Supply chain management and Advanced Planning 4th edn, Chap 18. Springer, Berlin, pp 349–366

Meyr H, Wagner M, Rohde J (2008) Structure of advanced planning systems. In: Stadtler H, Kilger C(eds) Supply chain management and advanced planning 4th edn, Chap 5. Springer, Berlin, pp 109–115

Pibernik R (2005) Advanced available–to–promise: classification, selected methods and requirements for operations and inventory management. Int J Product Econ 93(94): 239–252

Pibernik R (2006) Managing stock–outs effectively with order fulfilment systems. J Manufact Technol Manage 17(6): 721–736

Quante R, Meyr H, Fleischmann M (2008) Revenue management and demand fulfilment: Matching applications, models, and software. Technical report, Institute for Production Management, Vienna University of Economics and Business Administration, Nordbergstr. 15, 1090 Wien, Austria (OR Spectrum to appear)

Schneeweiss C (2003) Distributed decision making, 2nd edn. Springer, Berlin

Stadtler H, Kilger C (2008) Eds. Supply Chain Management and Advanced Planning, 4th edn. Springer, Berlin

Talluri K, Van Ryzin G (2004) The theory and practice of revenue management. Kluwer, Boston

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Meyr, H. Customer segmentation, allocation planning and order promising in make-to-stock production. OR Spectrum 31, 229–256 (2009). https://doi.org/10.1007/s00291-008-0123-x

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00291-008-0123-x