Abstract

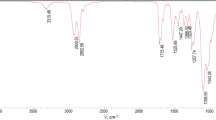

Polyurethane (PU) has been extensively used in multiple technologically critical applications because of its favorable physicochemical characteristics. The aim of this study is the development of patterned PU films by adopting an alkaline hydrolysis approach. This process generates amine functionality and microdomains on the PU surface. The surface functionality is investigated using various characterization techniques, such as amine content, contact angle, Fourier transform infrared spectroscopy. The inherent mechanical strength of PU films diminishes significantly with the hydrolysis time. The hydrophilicity on the surface is observed in terms of a decrease in the contact angle with respect to the pristine PU. The hydrolysis leads to a significant alteration in the surface morphology. The alkaline hydrolysis creates the valley and trough pattern on the surface of the PU matrix, which is confirmed using SEM and 3D profilometer.

Graphic abstract

Similar content being viewed by others

References

Bahrami S, Solouk A, Mirzadeh H, Seifalian AM (2019) Electroconductive polyurethane/graphene nanocomposite for biomedical applications. Compos Part B Eng 168:421–431. https://doi.org/10.1016/j.compositesb.2019.03.044

Lutzweiler G, Barthes J, Koenig G, Kerdjoudj H, Mayingi J, Boulmedais F, Schaaf P, Drenckhan W, Vrana NE (2019) Modulation of cellular colonization of porous polyurethane scaffolds via the control of pore interconnection size and nanoscale surface modifications. ACS Appl Mater Interfaces 11:19819–19829. https://doi.org/10.1021/acsami.9b04625

Han Y, Hu J, Xin Z (2019) Facile preparation of high solid content waterborne polyurethane and its application in leather surface finishing. Prog Org Coat 130:8–16. https://doi.org/10.1016/j.porgcoat.2019.01.031

Zhao J, Zhu W, Wang X, Liu L, Yu J, Ding B (2020) Fluorine-free waterborne coating for environmentally friendly, robustly water-resistant, and highly breathable fibrous textiles. ACS Nano 14:1045–1054. https://doi.org/10.1021/acsnano.9b08595

Jaganathan SK, Mani MP (2018) Electrospun polyurethane nanofibrous composite impregnated with metallic copper for wound-healing application. Biotech. https://doi.org/10.1007/s13205-018-1356-2

Cheng Y, Miao D, Kong L, Jiang J, Guo Z (2019) Preparation and performance test of the super-hydrophobic polyurethane coating based on waste cooking oil. Coatings 9:861. https://doi.org/10.3390/coatings9120861

Barz J, Haupt M, Oehr C, Hirth T, Grimmer P (2019) Stability and water wetting behavior of superhydrophobic polyurethane films created by hot embossing and plasma etching and coating. Plasma Process Polym 16:8–10. https://doi.org/10.1002/ppap.201800214

Meng F, Qiao Z, Yao Y, Luo J (2018) Synthesis of polyurethanes with pendant azide groups attached on the soft segments and the surface modification with mPEG by click chemistry for antifouling applications. RSC Adv 8:19642–19650. https://doi.org/10.1039/c8ra02912a

Kwiatkowski K, Nachman M (2017) The abrasive wear resistance of the segmented linear polyurethane elastomers based on a variety of polyols as soft segments. Polymers. https://doi.org/10.3390/polym9120705

Alves P, Cardoso R, Correia TR, Antunes BP, Correia IJ, Ferreira P (2014) Surface modification of polyurethane films by plasma and ultraviolet light to improve haemocompatibility for artificial heart valves. Colloids Surf B Biointerf 113:25–32. https://doi.org/10.1016/j.colsurfb.2013.08.039

Bahrami N, Nouri Khorasani S, Mahdavi H, Ghiaci M, Mokhtari R (2019) Low-pressure plasma surface modification of polyurethane films with chitosan and collagen biomolecules. J Appl Polym Sci 136:1–10. https://doi.org/10.1002/app.47567

Zhang J, Sun Z, Zhu H, Guo Q, He C, Xia A, Mo H, Huang X, Shen J (2016) Novel triphosphorylation polyurethane nanoparticles for blood-contacting biomaterials’ coating. J Mater Chem B 4:1116–1121. https://doi.org/10.1039/c5tb01877c

Xu S, Li X, Sui G, Du R, Zhang Q, Fu Q (2020) Plasma modification of PU foam for piezoresistive sensor with high sensitivity, mechanical properties and long-term stability. Chem Eng J 381:122666. https://doi.org/10.1016/j.cej.2019.122666

Jaganathan SK, Balaji A, Vellayappan MV, Subramanian AP, John AA, Asokan MK, Supriyanto E (2015) Review: radiation-induced surface modification of polymers for biomaterial application. J Mater Sci 50:2007–2018. https://doi.org/10.1007/s10853-014-8718-x

Cernadas T, Morgado S, Alves P, Gonçalves FAMM, Correia TR, Correia IJ, Ferreira P (2020) Preparation of functionalized poly(caprolactone diol)/castor oils blends to be applied as photocrosslinkable tissue adhesives. J Appl Polym Sci. https://doi.org/10.1002/app.49092

Chen D, McKinley GH, Cohen RE (2016) Spontaneous wettability patterning via creasing instability. Proc Natl Acad Sci U S A 113:8087–8092. https://doi.org/10.1073/pnas.1522700113

Waugh DG, Toccaceli C, Gillett AR, Ng CH, Hodgson SD, Lawrence J (2016) Surface treatments to modulate bioadhesion: a critical review. Rev Adhes Adhes 4:69–103. https://doi.org/10.7569/RAA.2016.097304

BrzozowskaMaassenGoh Zhi RongBenkeLimMarzinelliJańczewskiTeoVancso AMSRPICSEMDSLMGJ (2017) Effect of variations in micropatterns and surface modulus on marine fouling of engineering polymers. ACS Appl Mater Interfaces 9:17508–17516. https://doi.org/10.1021/acsami.6b14262

Irving M, Murphy MF, Lilley F, French PW, Burton DR, Dixon S, Sharp MC (2017) The use of abrasive polishing and laser processing for developing polyurethane surfaces for controlling fibroblast cell behaviour. Mater Sci Eng C 71:690–697. https://doi.org/10.1016/j.msec.2016.10.067

Jayasinghe HG, Tormos CJ, Khan M, Madihally S, Vasquez Y (2018) A soft lithography method to generate arrays of microstructures onto hydrogel surfaces. J Polym Sci Part B Polym Phys 56:1144–1157. https://doi.org/10.1002/polb.24634

Zwahr C, Voisiat B, Welle A, Günther D, Lasagni AF (2018) One-step fabrication of pillar and crater-like structures on titanium using direct laser interference patterning. Adv Eng Mater 20:1–9. https://doi.org/10.1002/adem.201800160

Munther M, Palma T, Angeron IA, Salari S, Ghassemi H, Vasefi M, Beheshti A, Davami K (2018) Microfabricated biomimetic placoid Scale-Inspired surfaces for antifouling applications. Appl Surf Sci 453:166–172. https://doi.org/10.1016/j.apsusc.2018.05.030

Chennell P, Feschet-Chassot E, Sautou V, Mailhot-Jensen B (2018) Preparation of ordered mesoporous and macroporous thermoplastic polyurethane surfaces for potential medical applications. J Biomater Appl 32:1317–1328. https://doi.org/10.1177/0885328218768643

Da LC, Huang YZ, Xie HQ (2017) Progress in development of bioderived materials for dermal wound healing. Regen Biomater 4:325–334. https://doi.org/10.1093/rb/rbx025

Shi Y, Cao X, Gao H (2016) Nanoscale The use of azide-alkyne click chemistry in recent syntheses and applications of polytriazole-based nanostructured polymers. Nanoscale 8:4864. https://doi.org/10.1039/c5nr09122e

Yang P, Wang Y, Lu L, Yu X, Liu L (2018) Surface hydrophobic modification of polyurethanes by diaryl carbene chemistry: Synthesis and characterization. Appl Surf Sci 435:346–351. https://doi.org/10.1016/j.apsusc.2017.11.121

Tran N, Le A, Ho M, Dang N, Thi Thanh HH, Truong L, Huynh DP, Hiep NT (2020) Polyurethane/polycaprolactone membrane grafted with conjugated linoleic acid for artificial vascular graft application. Sci Technol Adv Mater 21:56–66. https://doi.org/10.1080/14686996.2020.1718549

Bhogle CS, Pandit AB (2018) Ultrasound-assisted alkaline hydrolysis of waste poly(ethylene terephthalate) in aqueous and non-aqueous media at low temperature. Indian Chem Eng 60:122–140. https://doi.org/10.1080/00194506.2017.1310634

Lee SJ, Yun C, Park CH (2019) Electrically conductive and superhydrophobic textiles via pyrrole polymerization and surface hydrophobization after alkaline hydrolysis. Text Res J 89:1436–1447. https://doi.org/10.1177/0040517518773371

Singh S, Gupta B (2017) Development and characterization of nanosoy-reinforced dextran nanocomposite membranes. J Appl Polym Sci. https://doi.org/10.1002/app.44655

Le Gac PY, Choqueuse D, Melot D (2013) Description and modeling of polyurethane hydrolysis used as thermal insulation in oil offshore conditions. Polym Test 32:1588–1593. https://doi.org/10.1016/j.polymertesting.2013.10.009

Kościelniak-Ziemniak M, Hajduk B, Jarka P, Weszka J, Kustosz R, Kapis A, Gonsior M (2014) IR and microscopic studies of polyurethane surface in the polish extracorporeal ventricular assist device POLVAD-MEV. Arch Mater Sci Eng 68:10–19

Gewert B, Plassmann MM, Macleod M (2015) Pathways for degradation of plastic polymers floating in the marine environment. Environ Sci Process Impacts 17:1513–1521. https://doi.org/10.1039/c5em00207a

Wang C, Ma C, Mu C, Lin W (2017) Tailor-made zwitterionic polyurethane coatings: Microstructure, mechanical property and their antimicrobial performance. RSC Adv 7:27522–27529. https://doi.org/10.1039/c7ra04379a

Asefnejad A, Khorasani MT, Behnamghader A, Farsadzadeh B, Bonakdar S (2011) Manufacturing of biodegradable polyurethane scaffolds based on polycaprolactone using a phase separation method: physical properties and in vitro assay. Int J Nanomed 6:2375–2384. https://doi.org/10.2147/ijn.s15586

Chiono V, Mozetic P, Boffito M, Sartori S, Gioffredi E, Silvestri A, Rainer A, Giannitelli SM, Trombetta M, Nurzynska D et al (2014) Polyurethane-based scaffolds for myocardial tissue engineering. Interface Focus. https://doi.org/10.1098/rsfs.2013.0045

Fournier D, De Geest BG, Du Prez FE (2009) On-demand click functionalization of polyurethane films and foams. Polymer (Guildf) 50:5362–5367. https://doi.org/10.1016/j.polymer.2009.09.047

Strankowski M, Włodarczyk D, Piszczyk Ł, Strankowska J (2016) Polyurethane nanocomposites containing reduced graphene oxide, ftir, raman, and xrd studies. J Spectrosc. https://doi.org/10.1155/2016/7520741

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Somani, M., Mukhopadhyay, S. & Gupta, B. Surface features and patterning in hydrolytic functionalization of polyurethane films. Polym. Bull. 79, 2305–2319 (2022). https://doi.org/10.1007/s00289-021-03601-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-021-03601-4