Abstract

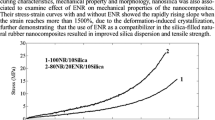

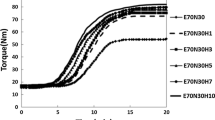

The properties of rubber composite depend on the compatibility between rubber and filler. This is specifically of concern when preparing composites with very different polarities of the rubber matrix and the filler. Natural rubber (NR) and halloysite nanotubes (HNT) are one of the examples of the incompatible system. Epoxidized natural rubber (ENR) was used as the main matrix, with halloysite nanotubes (HNT) as a filler, in order to obtain composites with improved performance. ENR was prepared in house using performic acid with a controlled reaction time to obtain samples with mole epoxide levels from 10 to 40 mol%. Varying the mole epoxide levels was expected to optimize the formulation for this rubber composite. The compounds obtained were then investigated for the rubber–filler interactions of the ENR and HNT. By increasing the mole percentage of epoxide, the scorch and cure times were decreased while the maximum torque and torque differences increased. The ENR at 40 mol% epoxide exhibited least filler–filler interaction as shown from the Payne effect together with the supporting result from FTIR spectrum. However, this ENR compound did not yield the optimum tensile strength due to the constraint on the rubber–filler interaction. This study revealed that the use of ENR with a suitable mole percent of epoxide can dramatically reduce the filler–filler interaction and hence enhance the dispersion of HNT, which was seen from SEM micrographs, and resulted in enhancement of the mechanical and dynamical properties of the composites.

Similar content being viewed by others

References

Arrighi V, McEwen I, Qian H, Prieto MS (2003) The glass transition and interfacial layer in styrene–butadiene rubber containing silica nanofiller. Polymer 44:6259–6266

Ismail H, Pasbakhsh P, Fauzi MA, Bakar AA (2008) Morphological, thermal and tensile properties of halloysite nanotubes filled ethylene propylene diene monomer (EPDM) nanocomposites. Polym Test 27:841–850

Jia Z, Luo Y, Guo B, Yang B, Du M, Jia D (2009) Reinforcing and flame-retardant effects of halloysite nanotubes on LLDPE. Polym Plast Technol Eng 48:607–613

Vahedi V, Pasbakhsh P, Chai S-P (2015) Toward high performance epoxy/halloysite nanocomposites: new insights based on rheological, curing, and impact properties. Mater Des 68:42–53

Rooj S, Das A, Thakur V, Mahaling R, Bhowmick AK, Heinrich G (2010) Preparation and properties of natural nanocomposites based on natural rubber and naturally occurring halloysite nanotubes. Mater Des 31:2151–2156

Paran S, Naderi G, Ghoreishy M (2016) XNBR-grafted halloysite nanotube core-shell as a potential compatibilizer for immiscible polymer systems. Appl Surf Sci 382:63–72

Du M, Guo B, Lei Y, Liu M, Jia D (2008) Carboxylated butadiene–styrene rubber/halloysite nanotube nanocomposites: interfacial interaction and performance. Polymer 49:4871–4876

Sahakaro K, Beraheng S (2008) Reinforcement of maleated natural rubber by precipitated silica. J Appl Polym Sci 109:3839–3848

Manna A, Tripathy D, De P, De S, Chatterjee M, Peiffer D (1999) Bonding between epoxidized natural rubber and clay in presence of silane coupling agent. J Appl Polym Sci 72:1895–1903

Ichazo MN, Albano C, Hernández M, González J, Peña J (2011) Characterization of natural rubber/cassava starch/maleated natural rubber formulations. Revista Latinoamericana de Metalurgia y Materiales 31:71–84

Marykutty C, Mathew G, Mathew E, Thomas S (2003) Studies on novel binary accelerator system in sulfur vulcanization of natural rubber. J Appl Polym Sci 90:3173–3182

Osaka N, Kato M, Saito H (2013) Mechanical properties and network structure of phenol resin crosslinked hydrogenated acrylonitrile-butadiene rubber. J Appl Polym Sci 129:3396–3403

Ran S, Zong X, Fang D, Hsiao BS, Chu B, Phillips RA (2001) Structural and morphological studies of isotactic polypropylene fibers during heat/draw deformation by in-situ synchrotron SAXS/WAXD. Macromolecules 34:2569–2578

Xu H, Liu J, Fang L, Wu C (2007) In situ grafting onto silica surface with epoxidized natural rubber via solid state method. J Macromol Sci Part B Phys 46:693–703

Li S, Xu T, Jia Z, Zhong B, Luo Y, Jia D, Peng Z (2018) Preparation and stress-strain behavior of in-situ epoxidized natural rubber/SiO2 hybrid through a sol-gel method. Express Polym Lett 12:180–185

Gelling I (1985) Modification of natural rubber latex with peracetic acid. Rubber Chem Technol 58:86–96

Van Zyl AJ, Graef SM, Sanderson RD, Klumperman B, Pasch H (2003) Monitoring the grafting of epoxidized natural rubber by size-exclusion chromatography coupled to FTIR spectroscopy. J Appl Polym Sci 88:2539–2549

Poh B, Lee K (1994) FTIR study of thermal oxidation of ENR. Eur Polymer J 30:17–23

Ismail H, Salleh S, Ahmad Z (2013) Properties of halloysite nanotube (HNT) filled SMR L and ENR 50 nanocomposites. Int J Polym Mater Polym Biomater 62:314–322

Hakim R, Ismail H (2009) Comparison of the effects of organoclay loading on the curing and mechanical properties of organoclay-filled epoxidised natural rubber nanocomposites and organoclay-filled natural rubber nanocomposites. J Phys Sci 20:37–59

Du M, Guo B, Jia D (2010) Newly emerging applications of halloysite nanotubes: a review. Polym Int 59:574–582

Zhixin J, Yuanfang L, Shuyan Y, Mingliang D, Baochun G, Demin J (2011) Styrene-butadiene rubber/halloysite nanotubes composites modified by epoxidized natural rubber. J Nanosci Nanotechnol 11:10958–10962

Frost RL (1995) Fourier transform Raman spectroscopy of kaolinite, dickite and halloysite. Clays Clay Miner 43:191–195

Saramolee P, Lopattananon N, Sahakaro K (2014) Preparation and some properties of modified natural rubber bearing grafted poly (methyl methacrylate) and epoxide groups. Eur Polymer J 56:1–10

Chuayjuljit S, Yaowsang C, Na-Ranong N, Potiyaraj P (2006) Oil resistance and physical properties of in situ epoxidized natural rubber from high ammonia concentrated latex. J Appl Polym Sci 100:3948–3955

Burfield DR, Lim KL, Law KS (1984) Epoxidation of natural rubber latices: methods of preparation and properties of modified rubbers. J Appl Polym Sci 29:1661–1673

Ayala J, Hess W, Dotson A, Joyce G (1990) New studies on the surface properties of carbon blacks. Rubber Chem Technol 63:747–778

Kaewsakul W, Sahakaro K, Dierkes WK, Noordermeer JW (2014) Cooperative effects of epoxide functional groups on natural rubber and silane coupling agents on reinforcing efficiency of silica. Rubber Chem Technol 87:291–310

Waesateh K, Saiwari S, Ismail H, Othman N, Soontaranon S, Hayeemasae N (2018) Features of crystallization behavior of natural rubber/halloysite nanotubes composites using synchrotron wide-angle X-ray scattering. Int J Polym Anal Charact 23:260–270

Hernández M, López-Manchado MA, Sanz A, Nogales A, Ezquerra TA (2011) Effects of strain-induced crystallization on the segmental dynamics of vulcanized natural rubber. Macromolecules 44:6574–6580

Masa A, Saito R, Saito H, Sakai T, Kaesaman A, Lopattananon N (2016) Phenolic resin-crosslinked natural rubber/clay nanocomposites: Influence of clay loading and interfacial adhesion on strain-induced crystallization behavior. J Appl Polym Sci 133:43214

White JL, Spruiell JE (1983) The specification of orientation and its development in polymer processing. Polym Eng Sci 23:247–256

Acknowledgement

We gratefully acknowledge the financial support of the Faculty of Science and Technology, Prince of Songkla University, Pattani Campus, through a SAT-ASEAN research grant (Grant No. SAT590594S). Also, we would like to thank the Research and Development Office (RDO), Prince of Songkla University, and Dr. Michael Currie for assistance with manuscript preparation.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hayeemasae, N., Waesateh, K., Saiwari, S. et al. Detailed investigation of the reinforcing effect of halloysite nanotubes-filled epoxidized natural rubber. Polym. Bull. 78, 7147–7166 (2021). https://doi.org/10.1007/s00289-020-03461-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-020-03461-4