Abstract

The curing behavior and microstructure of natural rubber/silica foams were studied. Error function-based and autocatalytic models were correlated with the curing characteristics data of samples. The incorporation of silica into natural rubber caused an increase in the foam density and decrease in the cell size. Moreover, by increasing the curing temperature, cell size became larger and cell size distribution became non-uniform. It was thought that the higher temperature of foaming limited the bubble growth due to faster curing reaction. Lower viscosity and lower strength of rubber at high temperature increased the cell coalescence resulting in larger cell size and non-uniform cell distribution.

Similar content being viewed by others

References

Joseph R (2004) Handbook of polymer foams. In: Eaves D (ed) Rapra Technology, UK

Ramasamy S, Ismail H, Munusamy Y (2012) Tensile and morphological properties of rice husk powder filled natural rubber latex foam. Polym Plast Technol Eng 51:1524–1529

Alex AS, Thomas D, Manu SK, Sreenivas N, Sekkar V, Gouri C (2018) Addition-cure, room temperature vulcanizing silicone elastomer based syntactic foams with glass and ceramic microballoons. Polym Bull 75:747–767

Wang L, Ji Y, Peng X (2018) A new two-step process to prepare microcellular epoxy foams based on kinetic analysis. J Mater Sci 53:1540–1555

Rathnayake I, Ismail H, Azahari B, Darsanasiri ND, Rajapakse S (2012) Synthesis and characterization of nano-silver incorporated natural rubber latex foam. Polym Plast Technol Eng 51:605–611

Shimbo M, Nomura T, Muratani K, Fukuruma K (2004) On foaming process of vulcanized rubber using physical blowing agent. In: Proceedings of ICAD2004 the third international conference on axiomatic design Seoul, June 21–24

Morton M (1999) Rubber technology. Springer, Berlin

Srilathakutty R, Joseph R, George KE (1999) Studies on microcellular soles based on natural rubber/polyethylene blends. J Mater Sci 34:1493–1495

Najib NN, Ariff ZM, Bakar AA, Sipaut CS (2011) Correlation between the acoustic and dynamic mechanical properties of natural rubber foam: effect of foaming temperature. Mater Des 32:505–511

Harnnarongchai W, Chaochanchaikul K (2015) Effect of blowing agent on cell morphology and acoustic absorption of natural rubber foam. Appl Mech Mater 804:25–29

Ariff ZM, Zakaria Z, Tay LH, Lee SY (2008) Effect of foaming temperature and rubber grades on properties of natural rubber foams. J Appl Polym Sci 107:2531–2538

Kim JH, Choi KC, Yoon JM (2006) The foaming characteristics and physical properties of natural rubber foams: effects of carbon black content and foaming pressure. J Ind Eng Chem 12:795–801

Vahidifar A, Nouri Khorasani S, Park CB, Naguib HE, Khonakdar HA (2016) Fabrication and characterization of closed-cell rubber foams based on natural rubber/carbon black by one-step foam processing. Ind Eng Chem 55:2407–2416

Sritapunya T (2014) Study on preparation and properties of foam rubber from natural rubber ribbed smoked sheet using salt of amino alcohol and carbonic acid as foaming agent. Adv Mater Res 1044:115–118

Najib NN, Ariff ZM, Manan NA, Bakar AA, Sipaut CS (2009) Effect of blowing agent concentration on cell morphology and impact properties of natural rubber foam. J Phys Sci 20:13–25

Charoeythornkhajhornchai P, Samthong C, Boonkerd K, Somwangthanaroj A (2017) Effect of azodicarbonamide on microstructure, cure kinetics and physical properties of natural rubber foam. J Cell Plast 53:287–303

Wang D, Prakashan K, Xia L, Xin Z, Zhang Z (2018) Foaming of trans-polyisoprene using N2 as the blowing agent. Polym Adv Technol 29:716–725

Ismail H, Salleh SZ, Ahmad Z (2011) Curing characteristics, mechanical, thermal, and morphological properties of halloysite nanotubes (HNTs)-filled natural rubber nanocomposites. Polym Plast Technol Eng 50:681–688

Roy K, Potiyaraj P (2019) Exploring the comparative effect of silane coupling agents with different functional groups on the cure, mechanical and thermal properties of nano-alumina (Al2O3)-based natural rubber (NR) compounds. Polym Bull 76:883–902

Hayeemasae N, Ismail H (2019) Reinforcement of epoxidized natural rubber through the addition of sepiolite. Polym Compos 40:924–931

George SC, Rajan R, Thomas AA, Kim S (2016) The fabrication and properties of natural rubber-clay nanocomposites. Polym Test 51:165–173

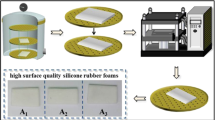

Bayat H, Fasihi M (2019) Effect of coupling agent on the morphological characteristics of natural rubber/silica composites foams. e-Polymers 19:430–436

Robledo-Ortiz JR, Zepeda C, Gomez C, Rodrigue D, Gonza lez-Nunez R (2008) Non-isothermal decomposition kinetics of azodicarbonamide in high density polyethylene using a capillary rheometer. Polym Test 27:730–735

Bhatti AS, Dollimore D, Goddard RJ, Donnell GO (1984) The effects of additives on the thermal decomposition of azodicarbonamide. Thermochim Acta 76:273–286

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Bayat, H., Fasihi, M. Curing characteristics and cellular morphology of natural rubber/silica composite foams. Polym. Bull. 77, 3171–3184 (2020). https://doi.org/10.1007/s00289-019-02907-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-019-02907-8