Abstract

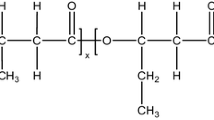

In order to improve the mechanical properties of PPC, a hyperbranched polymer with a large number of active epoxy groups at the end (epoxy-terminated hyperbranched polyester, EHBP) was synthesized and characterized by FTIR, NMR and GPC. Then, PPC/EHBP blends were prepared through melt-mixing. The effect of EHBP on the mechanical properties, thermal properties, viscosity and gas permeability of the PPC/EHBP blends is studied in detail based on the expected micro-crosslinking theory between EHBP and PPC. The results indicate that when the content of EHBP is 0.5 wt%, the tensile strength increased by 73.8%; elongation at break increased by 131.7%; the impact strength increased by 88.4%. The glass transition temperature increased from 40.71 to 44.44 °C upon addition of EHBP. Also, the addition of EHBP is beneficial to the improvement of the gas barrier property of PPC. The modification mechanism is discussed. It indicates that upon addition of EHBP, both physical hydrogen bonding and chemical bonding occurred, based on gel content calculation, which is in line with expectations. When the content of EHBP is 0.5 wt%, the degree of chemical micro-crosslinking is about 9.2%.

Similar content being viewed by others

References

Stewart R (2007) Biopolymers—greater consumer awareness drives growth of biobased-resins market. Plast Eng 63:24

Inoue S, Koinuma H, Tsuruta T (1969) Copolymerization of carbon dioxide and epoxide with organometallic compounds. Macromol Chem Phys 130:210–220

Nakano K, Hashimoto S, Nakamura M, Kamada T, Nozaki K (2011) Stereocomplex of poly(propylene carbonate): synthesis of stereogradient poly(propylene carbonate) by regio- and enantioselective copolymerization of propylene oxide with carbon dioxide. Angew Chem Int Edit 50:4868–4871

Aikawa S, Yoshida Y, Nishiyama S, Noguchi H, Shoji A (2006) Optical properties of poly(propylene carbonate) which contains C-60(OH)(n) structure in the end of polymer chain. Mol Cryst Liq Cryst 445:315–321

Ge X, Li X, Zhu Q, Li L, Meng Y (2004) Preparation and properties of biodegradable poly(propylene carbonate)/starch composites. Polym Eng Sci 44:2134–2140

Qu H, Wang Y, Ye Y, Zhou W, Bai S, Zhou X, Peng H, Xie X, Mai Y (2017) A promising nanohybrid of silicon carbide nanowires scrolled by graphene oxide sheets with a synergistic effect for poly(propylene carbonate) nanocomposites. J Mater Chem A 5:22361–22371

Kuang T, Li K, Chen B, Peng X (2017) Poly(propylene carbonate)-based in situ nanofibrillar biocomposites with enhanced miscibility, dynamic mechanical properties, rheological behavior and extrusion foaming ability. Compos Pt B Eng 123:112–123

Di Lorenzo ML, Ovyn R, Malinconico M, Rubino P, Grohens Y (2015) Peculiar crystallization kinetics of biodegradable poly(lactic acid)/poly(propylene carbonate) blends. Polym Eng Sci 55:2698–2705

Zhang N, Zeng C, Wang L, Ren J (2013) Preparation and properties of biodegradable poly(lactic acid)/poly(butylene adipate-co-terephthalate) blend with epoxy-functional styrene acrylic copolymer as reactive agent. J Polym Environ 21:286–292

Li X, Meng Y, Wang S, Rajulu AV, Tjong SC (2004) Completely biodegradable composites of poly(propylene carbonate) and short, lignocellulose fiber Hildegardia populifolia. J Polym Sci Pt B Polym Phys 42:666–675

Ge X, Zhu Q, Meng Y (2006) Fabrication and characterization of biodegradable poly(propylene carbonate)/wood flour composites. J Appl Polym Sci 99:782–787

Chang H, Li Q, Xu C, Li R, Wang H, Bu Z, Lin T (2017) Wool powder: an efficient additive to improve mechanical and thermal properties of poly(propylene carbonate). Compos Sci Technol 153:119–127

Kong J, Li Z, Cao Z, Han C, Dong L (2017) The excellent gas barrier properties and unique mechanical properties of poly(propylene carbonate)/organo-montmorillonite nanocomposites. Polym Bull 74:5065–5082

Pang S, Xu N, Xu G, Pan L, Lin Q, Wang X (2013) Preparation and properties of 4,4-diphenylmethane diisocyanate blocking modified poly(propylene carbonate). J Appl Polym Sci 128:2020–2029

Peng S, An Y, Chen C, Fei B, Zhuang Y, Dong L (2003) Thermal degradation kinetics of uncapped and end-capped poly(propylene carbonate). Polym Degrad Stabil 80:141–147

Wang X, Weng Y, Wang W, Huang Z, Wang Y (2016) Modification of poly(propylene carbonate) with chain extender ADR-4368 to improve its thermal, barrier, and mechanical properties. Polym Test 54:301–307

Wang X, Diao X, Yang N, Weng Y, Wang W (2015) Chain extension and modification of polypropylene carbonate using diphenylmethane diisocyanate. Polym Int 64:1491–1496

Hao Y, Ge H, Han L, Liang H, Zhang H, Dong L (2013) Thermal, mechanical, and rheological properties of poly(propylene carbonate) cross-linked with polyaryl polymethylene isocyanate. Polym Bull 70:1991–2003

Kim YH, Webster OW (1992) Hyperbranched polyphenylenes. Macromolecules 25:5561–5572

Mourey TH, Turner SR, Rubinstein M, Frechet JMJ, Hawker CJ, Wooley KL (1992) Unique behavior of dendritic macromolecules—intrinsic-viscosity of polyether dendrimers. Macromolecules 25:2401–2406

Yao Q, Li C, Huang H, Chen H, Liu B (2017) Waterborne carboxyl-terminated hyperbranched oligomer polyester ligand: synthesis, characterization and chelation with chromium(III). J Mol Struct 1143:371–377

Yu J, Chen Y (2010) Thermally cross-linkable hyperbranched polymers containing triphenylamine moieties: synthesis, curing and application in light-emitting diodes. Polymer 51:4484–4492

Wang T, Li M, Gao H, Wu Y (2011) Nanoparticle carriers based on copolymers of poly(epsilon-caprolactone) and hyperbranched polymers for drug delivery. J Colloid Interface Sci 353:107–115

Bhardwaj R, Mohanty AK (2007) Modification of brittle polylactide by novel hyperbranched polymer-based nanostructures. Biomacromolecules 8:2476–2484

Run M, Wang J, Yao M, Guo L, Wang H, Ba X (2013) Influences of hyperbranched poly(amide-ester) on the properties of poly(butylene succinate). Mater Chem Phys 139:988–997

Chen S, Zhang D, Jiang S, Jia D (2012) Preparation of hyperbranched epoxy resin containing nitrogen heterocycle and its toughened and reinforced composites. J Appl Polym Sci 123:3261–3269

Tang B, Liu X, Zhao X, Zhang J (2014) Highly efficient in situ toughening of epoxy thermosets with reactive hyperbranched polyurethane. J Appl Polym Sci 131:40614

Yokohara T, Yamaguchi M (2008) Structure and properties for biomass-based polyester blends of PLA and PBS. Eur Polym J 44:677–685

Li S, Wu Q, Lv T, Zhu H, Hou H, Lin Q, Li Y, Cui C, Guo Y (2017) Synthesis and characterization of hyperbranched polymer with epoxide-terminated group and application as modifier for epoxy/polyamide system. Polym Sci Ser B 59:328–336

Chen S, Xu Z, Zhang D (2018) Synthesis and application of epoxy-ended hyperbranched polymers. Chem Eng J 343:283–302

Liu D, Bian Q, Li Y, Wang Y, Xiang A, Tian H (2016) Effect of oxidation degrees of graphene oxide on the structure and properties of poly (vinyl alcohol) composite films. Compos Sci Technol 129:146–152

Acknowledgements

The authors thank the National Nature Science Foundation (51503007), Support Project of High-level Teachers in Beijing Municipal Universities in the Period of 13th Five-year Plan (CIT&TCD201804030) and Beijing Municipal Natural Science Fund-Key project of science and technology plan of Beijing Education Committee (KZ201810011017) for financial support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jin, Y., Sima, Y., Weng, Y. et al. Simultaneously reinforcing and toughening of poly(propylene carbonate) by epoxy-terminated hyperbranched polymer(EHBP) through micro-crosslinking. Polym. Bull. 76, 5733–5749 (2019). https://doi.org/10.1007/s00289-018-02676-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-018-02676-w