Abstract

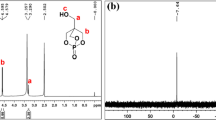

A polydichlorophosphazene was prepared by thermal ring-opening polymerization of hexachlorophosphonitrile (trimer). The functionalization of polydichlorophosphazene was done via substituting the chlorine groups with sodium salt of trifluroethanol and furfuryl alcohol and then structural properties of functionalized polyphosphazene (PPZ) was confirmed by GPC, FT-IR and NMR spectroscopic analysis. The PPZ was further blended with thermoplastic polyurethane (TPU) using solution casting method in anhydrous tetrahydrofuran solvent. The miscibility behavior of TPU/PPZ blends was observed via FTIR spectroscopy which unfolded the reason of compatibility of the blends due to intermolecular Hydrogen bonding interaction between the TPU and PPZ. Further, the thermal properties of the casted films were analyzed using thermogravimetric analysis (TGA) and differential scanning calorimetry (DSC) which revealed the increase in onset of degradation temperature of TPU with the increase of PPZ content. Also the char yields of TPU blends at 600 °C were increased upon increasing the amount of polyphosphazene from 5 to 20 wt%. The appearance of crystallinity in the TPU/PPZ blend due to heteronucleation effect by PPZ was analyzed by X-ray diffractometer. Besides this, the morphological changes of the TPU/PPZ blended films were investigated by scanning electron microscopy which exposed the homogeneity in the blend (d). The flame-retardant properties were evaluated using limiting oxygen index (LOI) analyzer and UL-94 (vertical burning test) showing the rating of V0 with achieved LOI value of 31.4% for the blend (d). Moreover, the films were characterized in terms of mechanical properties (as per relevant ASTM standards) using UTM which demonstrated that the addition of 20 wt% PPZ in the blend enhanced the tensile strength by about 110% and decreased the elongation at break by nearly 13%.

Similar content being viewed by others

References

Allcock HR (2003) Chemistry and applications of polyphosphazenes, 1st edn. Wiley-Interscience Hoboken, NJ

Allcock HR, Kugel RL (1965) Synthesis of high polymeric alkoxy and aryloxyphosphonitriles. J Am Chem Soc 87:4216. doi:10.1021/ja01096a056

Allcock HR (1976) Polyphosphazenes: new polymers with inorganic back bone atoms. Science 193:1214–1219. doi:10.1126/science.193.4259.1214

Allcock HR, Coley SM, Manners I (1991) Poly [(aryloxy)carbophosphazenes]:synthesis, properties, and thermal transition behavior. Macromolecules 24(8):2024–2028. doi:10.1021/ma00008a048

Allcock HR, Kwon S, Pucher SR (1990) Bioerodible polymers with a phosphorus-nitrogen backbone. Polym Prepr 31(2):180–181

Xu SB, Zheng FA, Yang YG (1994) The synthesis and characterization of polydichlophosphazene and poly (β-naphthyloxy) phosphazene. Chem J Chin U 15(11):1730–1732 (in Chinese)

Qiu LY, Zhe KJ (1999) Application of polyphosphazenes in drug controlled release systems. J Func Polym 12(1):115–120 (in Chinese)

Bortolus P, Gleria M (1994) Photochemistry and photophysics of poly (organo phosphazenes) and related compounds: a reviews. III Applicative aspects. J Inorg Organomet P 4(3):205–236. doi:10.1007/BF00683716

Allcock HR, Cameron CG, Skloss TW, Meyers TS, Haw JF (1996) Molecular motion of phosphazene-bound nonlinear optical chromophores. Macromolecules 29(1):233–238. doi:10.1021/ma950452

Prange R, Allcock HR (1999) Teletic synthesis of the first phosphazene siloxane block copolymers. Macromolecules 32(19):6390–6392. doi:10.1021/ma991136o

Greisha YE, Benderb JD, Lakshmic S, Browna PW, Allcock HR, Laurencinc CT (2005) Low temperature formation of hydroxyapatite- poly(alkyl oxybenzoate)phosphazene composites for biomedical applications. Biomaterials 26:1–9. doi:10.1016/j.biomaterials.2004.02.016

Li Z, Huang C, Hua JL, Qin JG, Zhou Y, Cheng Y (2004) A new post- functional approach to prepare second-order nonlinear optical polyphosphazenes containing sulfonyl-based chromophore. Macromolecules 37(2):371–376. doi:10.1021/ma035044h

Li Z, Qin JG (2003) Synthesis and structural characterization of a new C60-containing polyphosphazene. Acta Chim Sinica 61(8):1335–1337 (in Chinese)

Li Z, Qin JG (2003) Syntheses of a novel intermediate polyphosphazene and C60-contained polyphosphazenes. Chem J Chin U 24(7):1335–1337 (in Chinese)

Li Z, Zhan CM, Qin JQ (2000) Synthesis, characterization of polyphosphazenes and their applications as new functional materials. J Func Polym 13(2):240–246 (in Chinese)

Potin P, Jaeger RD (1991) Polyphosphazenes: synthesis, structures, properties, applications. Eur Polym J 27:341–348. doi:10.1016/0014-3057(91)90185-Q

Gabino AC, Francisco JG, Paloma GE, Fidalgo JI, Garcia JL (2003) A simplified and convenient laboratory-scale preparation of 14 N or 15 N high molecular weight poly(dichlorophosphazene) directly from PCl5. Chem Eur J 9:3833–3836. doi:10.1002/chem.200304750

Yang W, Jiang Z, Yang J, Yang B, Lu H (2015) Preparation of thermoplastic polyester elastomer/cerium carbonate hydroxide composites containing aluminum phosphinate with improved flame-retardant and mechanical properties. Ind Eng Chem Res 54:11048–11055. doi:10.1021/acs.iecr.5b02687

Gallo E, Braun U, Schartel B, Russo P, Acierno D (2009) Halogen-free flame retarded poly(butylene terephthalate) (PBT) using metal oxides/PBT nanocomposites in combination with Aluminium phosphinate. Polym Degrad Stab 94:1245–1253. doi:10.1016/j.polymdegradstab.2009.04.014

Braun U, Schartel B (2008) Flame retardancy mechanisms of aluminium phosphinate in combination with melamine cyanurate in glass-fibre-reinforced poly (1,4-butylene terephthalate). Macromol Mater Eng 293:206–217. doi:10.1002/mame.200700330

Yang W, Yang BH, Lu HD, Song L, Hu Y (2014) Effect of modified carbon nanotube on the thermal behavior, flame retardancy and mechanical properties of poly (1,4-butylene terephthalate)/aluminium phosphinate composites. Ind Eng Chem Res 53:18489–18496. doi:10.1021/ie503039e

Hassan M, Reddy KR, Haque E, Minett AI, Gomes VG (2013) High-yield aqueous phase exfoliation of graphene for facile nanocomposite synthesis via emulsion polymerization. J Colloid Interface Sci 410:43–51. doi:10.1016/j.jcis.2013.08.006

Lee RY, Kim SC, Lee H, Jeong HM, Raghu AV, Reddy KR, Kim BK (2011) Graphite oxides as effective fire retardants of epoxy resin. Macromol Res 19(1):66–71. doi:10.1007/s13233-011-0106-7

Han S, Lee HI, Jeong HM, Kyukim B, Raghu AV, Reddy KR (2016) Graphene modified lipophilically by stearic acid and its composite with low density polyethylene. J Macromol Sci Part B Phys 53:1193–1204. doi:10.1080/00222348.2013.879804

Son DR, Raghu AV, Reddy KR, Jeong HM (2016) Compatibility of thermally reduced graphene with polyesters. J Macromol Sci Part B Phys 55(11):1099–1110. doi:10.1080/00222348.2016.1242529

Hassan M, Reddy KR, Haque E, Minett AI, Gomes VG (2013) High-yield aqueous phase exfoliation of graphene for facile nanocomposite synthesis via emulsion polymerization. J Colloid Interface Sci 410:43–51. doi:10.1016/j.jcis.2013.08.006

Khan MU, Reddy KR, Snguanwongchai T, Haque E, Gomes VG (2016) Polymer brush synthesis on surface modified carbon nanotubes via in situ emulsion polymerization. Colloid Polym Sci 294:1599–1610. doi:10.1007/s00396-016-3922-7

Reddy KR, Sin BC, Ryu KS, Noh J, Leea YI (2009) In situ self-organization of carbon black–polyaniline composites from nanospheres to nanorods: synthesis, morphology, structure and electrical conductivity. Synth Met 159:1934–1939. doi:10.1016/j.synthmet.2009.06.018

Reddy KR, Karthik KV, Prasad SBB, Soni SK, Jeong HM, Raghu AV (2016) Enhanced photocatalytic activity of nanostructured titanium dioxide/polyaniline hybrid photocatalysts. Polyhedron 120:169–174. doi:10.1016/j.poly.2016.08.029

Reddy KR, Hassan M, Gomes VG (2015) Hybrid nanostructures based on titanium dioxide for enhanced photo catalysis. Appl Catal A 489:1–16. doi:10.1016/j.apcata.2014.10.001

Reddy KR, Lee KP, Gopalan AI, Showkat AM (2006) Facile synthesis of hollow spheres of sulfonated polyanilines. Polym J 38(4):349–354. doi:10.1295/polymj.38.349

Mallakpour S, Behranvand V (2016) Nanocomposites based on biosafe nano ZnO and different polymeric matrixes for antibacterial, optical, thermal and mechanical applications. Euro Polym J 84:377–403. doi:10.1016/j.eurpolymj.2016.09.028

Reddy KR, Lee KP, Gopalan AI, Showkat AM (2007) Self-assembly directed synthesis of poly (ortho-toluidine)-metal (Gold and Palladium) composite nanospheres. J Nanosci Nanotechnol 7:3117–3125. doi:10.1166/jnn.2007.692

Singh RP, Das CK, Mustafi SK (2002) Polymer blends and alloys an overview, 1st edn. Asian Book Private Limited, New Delhi

Oertel G (1994) Polyurethane handbook, vol 22, 2nd edn. Munich, Hansa

Bakhshi H, Yeganeh H, Mehdipour-Ataei S, Solouk A, Irani S (2013) Polyurethane coatings derived from 1,2,3-triazole-functionalized soybean oil-based polyols: studying their physical, mechanical, thermal, and biological properties. Macromolecules 46:7777. doi:10.1021/ma401554c

Randall D, Lee S (2003) The polyurethanes book. John Wiley & Sons, New York

Choi SH, Kim DH, Raghu AV, Reddy KR, Lee H, Yoon KS, Jeong HM, Kim BK (2012) Properties of graphene/waterborne polyurethane nanocomposites cast from colloidal dispersion mixtures. J Macromol Sci R Part B Phys 51:197–207. doi:10.1080/00222348.2011.583193

Hamerton I (1997) Recent developments in epoxy resins. Rapra Technology Limited, Shawbury

Czub P, Bończa-Tomaszewski Z, Penczek P, Pielichowski J (2002) Chemistry and technology of epoxy resin. Wydawnictwa Naukowo-Techniczne, Warszawa

May CA (1988) Epoxy resins chemistry and technology, 2nd edn. Marcel Dekker Inc., New York

Jeng RJ, Shau SM, Lin JJ, Su WC, Chiu YS (2002) Euro Polym J 38:683. doi:10.1016/S0014-3057(01)00246-4

Melchers RE, Jiang X (2006) Estimation of models for durability of epoxy coatings in water ballast tanks. Ships Offshore Struct 1:61–70. doi:10.1533/saos.2004.0006

Reddy KR, Raghu AV, Jeong HM (2009) Synthesis and characterization of pyridine-based polyurethanes. Des Monomers Polym 12:109–118. doi:10.1163/156855509X412054

Reddy KR, Raghu AV, Jeong HM (2008) Synthesis and characterization of novel polyurethanes based on 4,4′-{1,4-phenylenebis[methylylidenenitrilo]}diphenol. Polym Bull 60:609–616. doi:10.1007/s00289-008-0896-8

Chattopadhyay DK, Webster DC (2009) Thermal stability and flame retardancy of polyurethanes. Prog Polym Sci 34:1068–1133. doi:10.1016/j.progpolymsci.2009.06.002

Wang C, Zheng Y, Su Y, Fan J, Qin Q, Zhao Z (2016) A novel biodegradable polyurethane based on poly (3-hydroxybutyrate-co-3-hydroxyvalerate) and poly(ethylene glycol) as promising biomaterials with the improvement of mechanical property and hemocompatibility. Polym Chem 7:6120–6132. doi:10.1039/x0xx00000x

Choi SH, Kim DH, Raghu AV, Reddy KR, Lee HI, Yoon KS, Jeong HM, Kim BK (2012) Properties of graphene/waterborne polyurethane nanocomposites cast from colloidal dispersion mixtures. J Macromol Sci Part B Phys 51:197–207. doi:10.1080/00222348.2011.583193

Acknowledgements

We gratefully thank to the director, Defence Materials and Stores Research and Development Establishment Kanpur, India for granting the kind research facilities and financial support for the research work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Singh, K.P., Mishra, A., Kumar, N. et al. Evaluation of thermal, morphological and flame-retardant properties of thermoplastic polyurethane/polyphosphazene blends. Polym. Bull. 75, 2415–2430 (2018). https://doi.org/10.1007/s00289-017-2156-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-017-2156-2