Abstract

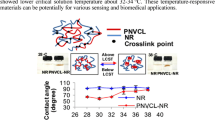

Temperature-responsive polymers are smart materials that respond to changes in temperature and have a wide range of applications, ranging from sensing to biomedical fields. In this work, we investigated the synthesis and temperature-responsive behavior of responsive elastomer based on N-isopropylacrylamide-grafted natural rubber. The grafting reaction was carried out using deproteinized natural rubber (DPNR) latex and potassium persulfate as free radical initiator. The temperature responsiveness of the graft copolymers was investigated using water swelling and contact angle measurements, and compared with that of pure DPNR. The lower critical solution temperature of the graft copolymer was found to be in the range 30–34 °C, whereas the DPNR was not responsive to temperature. Furthermore, the graft copolymer exhibited temperature responsiveness in a solid state. As the temperature responsiveness of the graft copolymer is close to the human body temperature, it can be used in biomedical applications. Dye adsorption studies revealed the Langmuir isotherm, indicating monolayer coverage. The technique proposed in this study produces a temperature-responsive natural rubber, with potential applications as a responsive material for use in sensing and biomedical products.

Similar content being viewed by others

References

Almeida H, Amaral MH, Lobão P (2012) Temperature and pH stimuli-responsive polymers and their applications in controlled and self-regulated drug delivery. J Appl Pharm Sci 02:01–10

Chen J-K, Chang C-J (2014) Fabrications and applications of stimulus-responsive polymer films and patterns on surfaces: a review. Materials 7:805–875

Ward MA, Georgiou TK (2011) Thermoresponsive polymers for biomedical applications. Polymers 3:1215

Mark B, Overberger CG, Menges G (1986) Encyclopedia of polymer science and engineering. Wiley 6:492

Chee C-K, Rimmer S, Soutar I, Swanson L (2006) Synthesis and conformational behaviour of luminescently labelled poly[styrene-graft-(N-isopropyl acrylamide)] copolymers. Polym Int 55:740–748

Abdulkadir A, Hazer B (2008) Poly(N-isopropylacrylamide) thermoresponsive cross-linked conjugates containing polymeric soybean oil and/or polypropylene glycol. Eur Polym J 44:1701–1713

Zhang J, Chu LY, Cheng CJ, Mi DF, Zhou MY, Ju XJ (2008) Graft-type poly(N-isopropylacrylamide-co-acrylic acid) microgels exhibiting rapid thermo- and pH-responsive properties. Polymer 49:2595–2603

Liu R, Fraylich M, Saunders BR (2009) Thermoresponsive copolymers: from fundamental studies to applications. Colloid Polym Sci 287:627–643

Yi G, Huang Y, Xiong F, Liao B, Yang J, Chen X (2011) Preparation and swelling behaviors of rapid responsive semi-IPN NaCMC/PNIPAm hydrogels. J Wuhan Univ Technol Mater Sci Ed 26:1073–1078

Abdullah Al N, Lee KS, Mosaiab T, Park SY (2013) pH and thermo-responsive poly(N-isopropylacrylamide) copolymer grafted to poly(ethylene glycol). J Appl Polym Sci 130:168–174

Ifuku S, Miwa T, Morimoto M, Saimoto H (2013) Thermoresponsive chitosan/N-isopropylacrylamide copolymer through atom transfer radical polymerization. Int J Biol Macromol 52:14–19

Kang H, Liu R, Huang Y (2013) Synthesis of ethyl cellulose grafted poly (n-isopropylacrylamide) copolymer and its micellization. Acta Chim Sin 71:114–120

Wang Y, Qin J, Wei Y, Li C, Ma G (2013) Preparation strategies of thermo-sensitive P(NIPAM-co-AA) microspheres with narrow size distribution. Powder Technol 236:107–113

Hermann A, Mruk R, Roskamp RF, Scherer M, Ma L, Zentel R (2014) Poly(N -isopropylacrylamide)-modified styrene-butadiene rubber as thermoresponsive material. Macromol Chem Phys 215:32–43

Jin S, Liu M, Chen S, Gao C (2008) Synthesis, characterization and the rapid response property of the temperature responsive PVP-g-PNIPAM hydrogel. Eur Polym J 44:2162–2170

Qin S, Geng Y, Discher DE, Yang S (2006) Temperature-controlled assembly and release from polymer vesicles of poly(ethylene oxide)-block- poly(N-isopropylacrylamide). Adv Mater 18:2905–2909

Hodorog ADR, Ibanescu C, Danu M, Simionescu BC, Rocha L, Hurduc N (2012) Thermo-sensitive polymers based on graft polysiloxanes. Polym Bull 69:579–595

Graves DF (2007) Rubber. In: Kent JA (ed) Handbook of industrial chemistry and biotechnology. Springer, New York, pp 689–718

Gamlin C, Markovic MG, Dutta NK, Choudhury NR, Matisons JG (2000) Structural effects on the decomposition kinetics of EPDM elastomers by high-resolution TGA and modulated TGA. J Therm Anal Calorim 59:319–336

Kangwansupamonkon W, Gilbert RG, Kiatkamjornwong S (2005) Modification of natural rubber by grafting with hydrophilic vinyl monomers. Macromol Chem Phys 206:2450–2460

Oliveira PC, Guimaraes A, Cavaille JY, Chazeau L, Gilbert RG (2005) Poly(dimethylaminoethyl methacrylate) grafted natural rubber from seeded emulsion polymerization. Polymer 46:1101–1105

Juntuek P, Ruksakulpiwat C, Chumsamrong P, Ruksakulpiwat Y (2011) Glycidyl methacrylate grafted natural rubber: synthesis, characterization, and mechanical property. J Appl Polym Sci 122:3152–3159

Satraphan P, Intasiri A, Tangpasuthadol V, Kiatkamjornwong S (2009) Effects of methyl methacrylate grafting and in situ silica particle formation on the morphology and mechanical properties of natural rubber composite films. Polym Adv Technol 20:473–486

Kochthongrasamee T, Prasassarakich P, Kiatkamjornwong S (2006) Effects of redox initiator on graft copolymerization of methyl methacrylate onto natural rubber. J Appl Polym Sci 101:2587–2601

Zhang S, Cao L, Shao F, Chen L, Jiao J, Gao W (2008) Grafting of methyl methacrylate onto natural rubber in supercritical carbon dioxide. Polym Adv Technol 19:54–59

Suksawad P, Yamamoto Y, Kawahara S (2011) Preparation of thermoplastic elastomer from natural rubber grafted with polystyrene. Eur Polym J 47:330–337

Arayapranee W, Rempel GL (2008) Morphology and mechanical properties of natural rubber and styrene-grafted natural rubber latex compounds. J Appl Polym Sci 109:1395–1402

Pukkate N, Kitai T, Yamamoto Y, Kawazura T, Sakdapipanich J, Kawahara S (2007) Nano-matrix structure formed by graft-copolymerization of styrene onto natural rubber. Eur Polym J 43:3208–3214

Promdum Y, Klinpituksa P, Ruamcharoen J (2009) Grafting copolymerization of natural rubber with 2-hydroxyethyl methacrylate for plywood adhesion improvement. Songklanakarin J Sci Technol 31:453–457

Amnuaypanich S, Ratpolsan P (2009) Pervaporation membranes from natural rubber latex grafted with poly(2-hydroxyethyl methacrylate) (NR-g-PHEMA) for the separation of water-acetone mixtures. J Appl Polym Sci 113:3313–3321

Wongthep W, Srituileong S, Martwiset S, Amnuaypanich S (2013) Grafting of poly(vinyl alcohol) on natural rubber latex particles. J Appl Polym Sci 127:104–110

Wongthong P, Nakason C, Pan Q, Rempel GL, Kiatkamjornwong S (2012) Grafting of maleic anhydride onto deproteinized natural rubber via differential microemulsion polymerization. Adv Trends Eng Mater Appl 183–190

Nakason C, Kaesaman A, Supasanthitikul P (2004) The grafting of maleic anhydride onto natural rubber. Polym Test 23:35–41

Nakason C, Kaesaman A, Yimwan N (2003) Preparation of graft copolymers from deproteinized and high ammonia concentrated natural rubber latices with methyl methacrylate. J Appl Polym Sci 87:68–75

Oshio A, Kitai T, Kawahara S, Kuroda H (2006) Investigation of high graft-copolymerization of styrene onto natural rubber. In: Polymer preprints, vol 55. Japan, p 3606

Pukkate N, Yamamoto Y, Kawahara S (2008) Mechanism of graft copolymerization of styrene onto deproteinized natural rubber. Colloid Polym Sci 286:411–416

Wongthong P, Nakason C, Pan Q, Rempel GL, Kiatkamjornwong S (2013) Modification of deproteinized natural rubber via grafting polymerization with maleic anhydride. Eur Polym J 49:4035–4046

Kookarinrat C, Paoprasert P (2015) Versatile one-pot synthesis of grafted-hydrogenated natural rubber. Iran Polym J 24:123–133

Nuntahirun P, Yamamoto O, Paoprasert P (2016) Preparation and temperature-responsive behavior of crosslinked polymers between poly(N-isopropylacrylamide) and natural rubber. Macrol Res 24:816–823

Fukuhara L, Miyano K, Yamamoto Y, Ishii H, Kawahara S (2015) Preparation of purified natural rubber by removal of proteins. Kobunshi Ronbunshu 72:1–6

Kawahara S, Klinklai W, Kuroda H, Isono Y (2004) Removal of proteins from natural rubber with urea. Polym Adv Technol 15:181–184

Halimatuddahliana IH, Akil HM (2005) The effect of dicumyl peroxide vulcanization on the properties and morphology of polypropylene/ethylene–propylene diene terpolymer/natural rubber blends. Int J Polym Mater 54:1169

Liu H, Chuai C, Iqbal M, Wang H, Kalsoom BB, Khattak M, Khattak MQ (2011) Improving foam ability of polypropylene by crosslinking. J Appl Polym Sci 122:973–980

Tamboli SM, Mhaske ST, Kale DD (2011) Improving foam ability of polypropylene by crosslinking. J Appl Polym Sci 122:973–980

Manaila E, Stelescu MD, Craciun G, Surdu L (2014) Effects of benzoyl peroxide on some properties of composites based on hemp and natural rubber. Polym Bull 71:2001–2022

Li D, Zhang X, Yao J, Simon GP, Wang H (2011) Stimuli-responsive polymer hydrogels as a new class of draw agent for forward osmosis desalination. Chem Commun 47:1710–1712

Park YI, Zhang B, Kuo C-Y, Martinez JS, Park J, Mallapragada S, Wang H-L (2013) Stimuli-responsive poly-N-isopropylacrylamide: phenylene vinylene oligomer conjugate. J Phys Chem C 117:7757–7763

Seddiki N, Aliouche D (2013) Synthesis, rheological behavior and swelling properties of copolymer hydrogels based on poly(N-isopropylacrylamide) with hydrophilic monomers. Bull Chem Soc Ethiop 27:447

Chanroj T, Paoprasert P (2016) Chlorohydrination of natural rubber latex using sodium hypochlorite for fuel-resistant properties. Rubber Chem Technol 89:251–261

Xia X, Hu Z (2004) Synthesis and light scattering study of microgels with interpenetrating polymer networks. Langmuir 20:2094–2098

Cai Y, Shen W, Loo SL, Krantz WB, Wang R, Fane AG, Hua X (2013) Towards temperature driven forward osmosis desalination using Semi-IPN hydrogels as reversible draw agents. Water Res 47:3773–3781

Hebeish A, Farag S, Sharaf S, Shaheen TI (2014) Thermal responsive hydrogels based on semi interpenetrating network of poly (NIPAm) and cellulose nanowhiskers. Carbohydr Polym 102:159–166

Zadrazil A, Stepánek F (2010) Investigation of thermo-responsive optical properties of a composite hydrogel. Colloid Surf A 372:115–119

Chen X (2015) Modeling of experimental adsorption isotherm data. Information 4:14–22

Dada AO, Olalekan AP, Olatunya AM, Dada O (2012) Langmuir, Freundlich, Temkin and Dubinin–Radushkevich isotherms studies of equilibrium sorption of Zn2+ unto phosphoric acid modified rice husk. IOSR J Appl Chem 3:38–45

Itodo AU, Itodo HU (2010) Sorption energies estimation using Dubinin–Radushkevich and Temkin adsorption isotherms. Life Sci J 7:31–39

Acknowledgements

This work is financially supported by the Thailand Research Fund (TRF) and the Faculty of Science and Technology, Thammasat University (TRG5880199) and the Thailand Graduate Institute of Science and Technology (TGIST: SCA-CO-2558-996-TH). The authors acknowledge the Central Scientific Instrument Center (CSIC), Department of Chemistry, Faculty of Science and Technology, and Thammasat University.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nuntahirun, P., Yamamoto, O. & Paoprasert, P. Temperature-responsive N-isopropylacrylamide-grafted natural rubber. Polym. Bull. 75, 1387–1401 (2018). https://doi.org/10.1007/s00289-017-2099-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-017-2099-7