Abstract

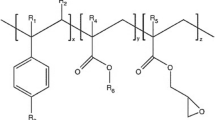

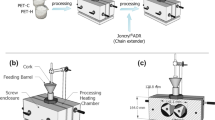

A simple approach for preparing recycled poly(ethylene terephthalate) (r-PET) with excellent processability and melt strength has been developed in this research. To increase the intrinsic viscosity of r-PET, a two-step chain extension process using a combination of SAG-008 and tetraglycidyl-4,4′-diaminodiphenylmethane (TGDDM) was investigated. To evaluate the chain extension degree of the modified r-PET, its intrinsic viscosity (IV) and rheological properties were characterized, and found to be correlated to the long-chain branches and molecular weight. The results indicated that the combination of SAG-008 and TGDDM at the optimized conditions provided the highest IV of 1.18 dl/g while controlling the gel formation to a low value. The increases in storage modulus, loss modulus and complex viscosity revealed the enhancement of melt strength and viscoelasticity of r-PET. The differential scanning calorimetry results showed that the crystallinity was reduced with the addition of chain extenders. On the other hand, stepwise annealing method from room temperature to crystal melting temperature promoted the crystallization, which was confirmed by wide-angle X-ray diffraction measurement.

Similar content being viewed by others

References

Lagaron JM, Catal R, Gavara R (2003) Structural characteristics defining high barrier properties in polymeric materials. J Mater Sci Technol 20:1–7

Awaja F, Pavel D (2005) Recycling of PET. Eur Polym J 41:1453–1477

Coltelli MB, Maggiore ID, Savi S, Aglietto M, Ciardelli F (2005) Modified styrene–butadiene–styrene block copolymer as compatibiliser precursor in polyethylene/poly(ethylene terephthalate) blends. Polym Degrad Stab 90:211–223

Coltelli MB, Aglietto M, Ciardelli F (2008) Influence of the transesterification catalyst structure on the reactive compatibilization and properties of poly(ethylene terephthalate) (PET)/dibutyl succinate functionalized poly(ethylene) blends. Eur Polym J 44:1512–1524

Coltelli MB, Bianchi S, Savi S, Liuzzo V, Aglietto M (2003) Metal catalysis to improve compatibility at PO/PET blends interfaces. Macromol Symp 204:227–236

Coltelli MB, Savi S, Maggiore ID, Liuzzo V, Aglietto M, Ciardelli F (2004) A model study of Ti(OBu) 4 catalyzed reactions during reactive blending of polyethylene (PE) and poly(ethylene terephthalate) (PET). Macromol Mater Eng 289:400–412

Zhang Y, Guo W, Zhang H, Wu C (2009) Influence of chain extension on the compatibilization and properties of recycled poly(ethylene terephthalate)/linear low density polyethylene blends. Polym Degrad Stabil 94:1135–1141

Dimonie D, Socoteanu R, Pop S, Fierascu I, Fierascu R, Petrea C, Zaharia C, Petrache M (2012) Overview on mechanical recycling by chain extension of POSTC-PET bottles. In: Material Recycling-Trends and Perspectives, Croatia, pp 85–114

Akkapeddi MK, Gervasi JA (1989) Chain extension of polyethylene terephthalate with polyacyllactams. US Patent 4857603

Inata H, Matsumura S (1985) Chain extenders for polyesters. I. Addition-type chain extenders reactive with carboxyl end groups of polyesters. J Appl Polym Sci 30:3325–3337

Inata H, Matsumura S (1986) Chain extenders for polyesters. III. Addition-type nitrogen-containing chain extenders reactive with hydroxyl end groups of polyesters. J Appl Polym Sci 32:4581–4594

Inata H, Matsumura S (1987) Chain extenders for polyesters. IV. Properties of the polyesters chain-extended by 2,2′-bis(2-oxazoline). J Appl Polym Sci 33:3069–3079

Inata H, Matsumura S (1987) Chain extenders for polyesters. V. Reactivities of hydroxyl-addition-type chain extender; 2,2′-bis(4h-3,1-benzoxazin-4-one). J Appl Polym Sci 34:2609–2617

Awaja F, Daver F, Kosior E, Cser F (2004) The effect of chain extension on the thermal behavior and crystallinity of reactive extruded recycled PET. J Therm Anal Calorim 78:865–884

Quintans J, Xanthos M, Dey SK, Yilmazer U (2000) Melt viscoelasticity of polyethylene terephthalate resins for low density extrusion foaming. Polym Eng Sci 40:554–566

Cardi N, Po R, Giannotta G, Occhiello E, Garbassi F, Messina G (1976) Chain extension of recycled poly(ethylene terephthalate) with 2,2′-bis(2-oxazoline). Cell Struct Funct 1:1501–1509

Karayannidis GP, Psalida EA (2000) Chain extension of recycled poly(ethylene terephthalate) with 2,2′-(1,4-phenylene)bis(2-oxazoline). J Appl Polym Sci 77:2206–2211

Luston J, Kronek J, Markus O, Janigova I, Bohme F (2007) Synthesis and polymerization reactions of cyclic imino ethers. 3. Poly(ester amide)s of the AA + BB type on the basis of 2-oxazolines. Polym Adv Technol 18:165–172

Raffa P, Coltelli MB, Savi S, Bianchi S, Castelvetro V (2012) Chain extension and branching of poly(ethylene terephthalate) (PET) with di- and multifunctional epoxy or isocyanate additives: an experimental and modelling study. React Funct Polym 72:50–60

Coccorullo I, Maio LD (2009) Theoretical and experimental study of foaming process with chain extended recycled PET. Express Polym Lett 3:84–96

Japon S, Boogh L, Leterrier Y, Månson JAE (2000) Reactive processing of poly(ethylene terephthalate) modified with multifunctional epoxy-based additives. Polymer 41:5809–5818

Xanthos M, Young MW, Karayanndis GP, Bikiaris DN (2001) Reactive modification of polyethylene terephthalate with polyepoxides. Polym Eng Sci 41:643–655

Heinssaron B, Clodoaldo S (2012) Chain extension of poly (ethylene terephthalate) by reactive extrusion with secondary stabilizer. Mater Res 15:467–472

Berkowitz S (1984) Viscosity and molecular weight relationships for poly(ethylene terephthalate) in hexafluoroisopropanol-pentafluorophenol using SEC-LALLS. J Appl Polym Sci 29:4353–4361

Pohl HA (1954) Determination of carboxyl end groups in polyester, polyethylene terephthalate. Anal Chem 26:357–363

Zhang Y, Zhang C, Li H, Du Z (2011) Effect of cyclotrimerization of bisphenol-A dicyanate monomer on poly(ethylene terephthalate) chain extension. Polym Eng Sci 51:1791–1796

Silva SML, Dias ML, Azuma C (2001) Reactive processing of nylon-6 and triphenyl phosphite. I. Molecular weight changes. J Polym Eng 21:543–558

Jacques B, Devaux J, Legras R, Nield E (1997) Reactions induced by triphenyl phosphite addition during melt mixing of PET/PBT blends: chromatographic evidence of a molecular weight increase due to the creation of bonds of two different natures. Polymer 38:5367–5377

Zhang Y, Zhang C, Li H, Du Z, Li C (2010) Chain extension of poly(ethylene terephthalate) with bisphenol-A dicyanate. J Appl Polym Sci 117:2003–2008

Xiao L, Wang H, Qian Q, Jiang X, Liu X, Huang B (2012) Molecular and structural analysis of epoxide-modified recycled poly(ethylene terephthalate) from rheological data. Polym Eng Sci 52:2127–2133

Münstedt H (1981) The influence of various deformation histories on elongational properties of low density polyethylene. Colloid Polym Sci 259:966–972

Chuang HK, Han CD (1984) Rheological behavior of polymer blends. J Appl Polym Sci 29:2205–2229

Bikiaris DN, Karayannidis GP (1996) Thermomechanical analysis of chain-extended PET and PBT. J Appl Polym Sci 60:55–61

Wang Y, Gao J, Ma Y, Agarwal US (2006) Study on mechanical properties, thermal stability and crystallization behavior of PET/MMT nanocomposites. Compos Part B Eng 37:399–407

Acknowledgements

The authors sincerely acknowledge ‘Shanghai industry-university-research cooperation project (CXY-2014-023)’ and ‘Jiangsu province science and technology achievements transformation project (SBA2014010034)’.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, K., Qian, J., Lou, F. et al. The effects of two-step reactive processing on the properties of recycled poly(ethylene terephthalate). Polym. Bull. 74, 2479–2496 (2017). https://doi.org/10.1007/s00289-016-1850-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-016-1850-9