Abstract

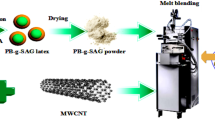

Titanium dioxide/polystyrene (TiO2/PS) core–shell nanoparticles (CSNPs) reinforced linear low density polyethylene/poly (lactic acid) (LLDPE/PLA) blends were developed by means of compounding and injection moulding. TiO2/PS CSNPs were prepared by ultrasound-assisted method while PLA was prepared by polycondensation of l-lactic acid, and were added to commercial grade LLDPE. The morphological analysis, carried out by electron microscopy, revealed significant phase separation in LLDPE/PLA blends but showed improved compatibility in LLDPE/PLA (TiO2/PS) nanocomposites. The thermal behaviour of the nanocomposites, as observed from thermogravimetric analysis (TGA), was also improved as compared to its blend counterparts. The incorporation of TiO2/PS CSNPs also resulted in better mechanical properties. With the addition of 1 phr TiO2/PS CSNPs, the tensile strength and elongation of LLDPE/PLA/(TiO2/PS) nanocomposites increased significantly. The results demonstrate the effect of TiO2/PS CSNPs in providing better interfacial adhesion between LLDPE and PLA which led to significant improvement in the mechanical strength of the nanocomposites by allowing effective load transfer in the nanocomposites system.

Graphical abstract

Similar content being viewed by others

References

CEH: Polyethylene Resins, Linear Low-Density (LLDPE). https://www.ihs.com/products/linear-low-density-polyethylene-chemical-economics-handbook.html. Accessed 16 July 2015

Balakrishnan H, Hassan A, Imran M, Wahit MU (2011) Aging of toughened polylactic acid nanocomposites: water absorption, hygrothermal degradation and soil burial analysis. J Polym Environ 19:863–875

Francis V, Subin SR, Bhat SG, Thachil ET (2012) Characterization of linear low-density polyethylene/poly(vinyl alcohol) blends and their biodegradability by Vibrio sp. isolated from marine benthic environment. J Appl Polym Sci 124(1):257–265

Raghul SS, Bhat SG, Chandrasekaran M, Francis V, Thachil ET (2014) Biodegradation of polyvinyl alcohol-low linear density polyethylene-blended plastic film by consortium of marine benthic vibrios. Int J Environ Sci Technol 11:1827–1834

Farhan M, Ab Aziz B, Mohamed R (2013) Biodegradability of starch based films blend with LLDPE and PVA. Adv Mater Res 795:115–118

Khoramnejadian Shahrzad (2011) Kinetic study of biodegradation of linear low density polyethylene/chitosan. Adv Environ Biol 5(10):3050–3055

Awal A, Rana M, Sain M (2015) Thermorheological and mechanical properties of cellulose reinforced PLA bio-composites. Mech Mater 80:87–95

Shimpi Navinchandra, Borane Mahesh, Mishra Satyendra, Kadam Meghraj (2012) Biodegradation of polystyrene (PS)-poly(lactic acid) (PLA) nanocomposites using Pseudomonas aeruginosa. Macromol Res 20(2):181–187

Shimpi NG, Borane M, Mishra S (2014) Preparation, characterization, and biodegradation of PS:PLA and PS:PLA:OMMT nanocomposites using Aspergillus niger. Polym Compos 35(2):263–272

Singh G, Kaur N, Bhunia H, Bajpai PK, Mandal UK (2012) Degradation behaviors of linear low density polyethylene and poly(l-lactic acid) blends. J Appl Polym Sci 124:1993–1998

Shimpi NG, Borane MD, Kadam M, Mishra S (2015) Effect of organically modified montmorillonite (OMMT) on biodegradation of PS:PLA and PS:PLA:OMMT using Phanerochaete chrysosporium. Polym Compos. doi:10.1002/pc.23694

Balakrishnan H, Hassan A, Wahit MU (2010) Mechanical, thermal, and morphological properties of polylactic acid/linear low density polyethylene blends. J Elastom Plast 42(3):223–239

Nuñez K, Rosales C, Perera R, Villarreal N, Pastor JM (2012) Poly(lactic acid)/low-density polyethylene blends and its nanocomposites based on sepiolite. Polym Eng Sci 52:988–1004. doi:10.1002/pen.22168

Liu G, Li Y-f, Yan F-y, Zhao Z-x, Zhou L-c, Xue Q-j (2005) Effect of Nanoscale SiO2 and TiO2 as the Fillers on the Mechanical Properties and Aging Behavior of Linear Low-Density Polyethylene/Low-Density Polyethylene Blends. J Polym Environ 13(4):339–348. doi:10.1007/s10924-005-5528-x

Zapata PA, Rabagliati FM, Lieberwirth I, Catalina F, Corrales T (2014) Study of the photodegradation of nanocomposites containing TiO2 nanoparticles dispersed in polyethylene and in poly(ethylene-cooctadecene). Polym Degrad Stab 109:106–114

Gutierrez J, Mondragon I, Tercjak A (2011) Morphological and optical behavior of thermoset matrix composites varying both polystyrene-block-poly(ethylene oxide) and TiO2 nanoparticle content. Polymer 52:5699–5707

Ekrachan C, Somsakun P, Okorn M, Joongjai P, Artiwan S, Bunjerd J (2012) LLDPE/TiO nanocomposites produced from different crystallite sizes of TiO via in situ polymerization. Chin Sci Bull 57(17):2177–2184. doi:10.1007/s11434-012-5021-6

Wang Z, Li G, Xie G, Zhan Z (2005) Dispersion behavior of TiO2 nanoparticles in LLDPE/LDPE/TiO2 nanocomposites. Macromol Chem Phys 206(2):258–262

Owpradit W, Jongsomjit B (2008) A comparative study on synthesis of LLDPE/TiO2 nanocomposites using different TiO2 by in situ polymerization with zirconocene/dMMAO catalyst. Mater Chem Phys 112(3):954–961

Luo HL, Sheng J, Wan YZ (2008) Preparation and characterization of TiO2/polystyrene core–shell nanospheres via microwave-assisted emulsion polymerization. Mater Lett 62(1):37–40

Fang X, Yang H, Gang W, Li W, Chen H, Wang M (2009) Preparation and characterization of low density polystyrene/TiO2 core–shell particles for electronic paper application. Curr Appl Phys 9(4):755–759

Chen ZM, Pan SJ, Yin HJ, Zhang LL, Ou EC, Xiong YQ, Xu WJ (2011) Facile synthesis of superhydrophobic TiO2/Polystyrene core-shell microspheres. Express Polym Lett 5(1):38–46

Li Y, Sun Z, Zhang J, Zhang K, Wang Y, Wang Z, Chen X, Zhu S, Yang B (2008) Polystyrene@TiO2 core-shell microsphere colloidal crystals and nonspherical macro-porous materials. J Colloid Interface Sci 325(2):567–572. doi:10.1016/j.jcis.2008.06.019

Vaezi MR, Arefian NA, Tabriz MF, Kandjani AE (2012) IJE Trans B Appl 25:131–135

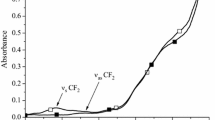

Gulmine JV, Janissek PR, Heise HM, Akcelrud L (2002) Polyethylene characterization by FTIR. Polym Test 21:557–563

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shimpi, N.G., Borane, M. & Mishra, S. TiO2/polystyrene core–shell nanoparticles as fillers for LLDPE/PLA blend: development, and morphological, thermal and mechanical properties. Polym. Bull. 73, 3049–3063 (2016). https://doi.org/10.1007/s00289-016-1640-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-016-1640-4