Abstract

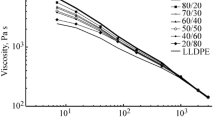

Flow behaviors and rheological properties of ethylene tetrafluoroethylene alternating copolymer (ETFE) under high-shear conditions were first reported. Flow instabilities, shear and extensional viscosities, and die swell of ETFE were investigated. Rheological behaviors of perfluorinated ethylene propylene copolymers (FEP), partially fluorinated ETFE, and non-fluorinated polyethylenes (PE) were compared for understanding the role of fluorine incursion on materials properties. It is found that (1) ETFE does not have sharkskin region or second smooth region which frequently occurs in FEP and linear PE; (2) critical shear stresses at which surface melt fracture occurs for the three polymers follow the order: FEP < ETFE < PE; (3) stable flow region narrows, die swell weakens, and flow activation energy increases when fluorine content of polymer increases. After time–temperature superposition, shifted shear viscosity, extensional viscosity, and elastic data (die swell) present universal scaling characteristic and superpose well in term of the same shift factors.

Similar content being viewed by others

Abbreviations

- D :

-

Diameter of the die (mm)

- L :

-

Length of the die (mm)

- Q:

-

Volume throughout rate (cm3•s−1)

- ΔP :

-

Pressure drops (Pa)

- ΔP ent :

-

Entrance pressure drops (Pa)

- τ a :

-

Apparent shear stress (Pa)

- τ tr :

-

True shear stress (Pa)

- \( \dot{\gamma}_{a} \) :

-

Apparent shear rate (s−1)

- \( \dot{\gamma}_{tr} \) :

-

True shear rate (s−1)

- η :

-

Shear viscosity (Pa s)

- σ e :

-

Extensional stress (Pa)

- \( \dot{\varepsilon } \) :

-

Extensional deformation rate (s−1)

- η e :

-

Extensional viscosity (Pa s)

- η 0 :

-

Zero-shear viscosity (Pa s)

- n :

-

Non-Newtonian index

- μ :

-

Trouton ratio, \( \mu = \frac{{\eta_{\text{e}} }}{\eta } \)

- α T :

-

Shift factor

- B :

-

Die swell ratio

- ρ s :

-

Polymer density at ambient temperature, g cm−3

- ρ m :

-

Polymer density at test temperature, g cm−3

References

Zhang Y, Li H, Zhang H (2008) Fluorine-containing functional materials. Chemical Industry Press, Beijing

Drobny JG (2000) Technology of fluoropolymers. CRC Press, Boca Raton

Wu C, Buck W, Chu B (2002) Light scattering characterization of an alternating copolymer of ethylene and tetrafluoroethylene. 2. Molecular weight distributions. Macromolecules 20(1):98–103

Chu B, Wu C (2002) Light scattering characterization of an alternating copolymer of ethylene and tetrafluoroethylene. Macromolecules 19(4):1285–1286

Feng J, Chan C-M, Weng L-T (2000) Influence of chain sequence structure of polymers on ToF-SIMS spectra. Polymer 41(7):2695–2699

Phongtamrug S, Tashiro K, Funaki A, Arai K, Aida S (2008) Structural study of a series of ethylene-tetrafluoroethylene copolymers with various ethylene contents, Part 1: Structure at room temperature investigated for uniaxially-oriented samples by an organized combination of 2D-WAXD/SAXS and IR/Raman spectra. Polymer 49(2):561–569

Phongtamrug S, Tashiro K, Funaki A, Arai K (2008) Structural study of a series of ethylene-tetrafluoroethylene copolymers with various ethylene contents, Part 2: phase transition behavior investigated by temperature dependent measurements of X-ray fiber diagrams. Polymer 49(23):5072–5083

Radice S, Del Fanti N, Zerbi G (1997) Phase transition in ethylene-tetrafluoroethylene(ETFE) alternating copolymer. A spectroscopic study. Polymer 38(11):2753–2758

Tuminello W, Buck W, Kerbow D (1993) Rheological molecular weight distribution determinations of ethylene/tetrafluoroethylene copolymers: implications for long-chain branching. Macromolecules 26(3):499–503

D’Aniello C, De Rosa C, Guerra G, Petraccone V, Corradini P, Ajroldi G (1995) Influence of constitutional defects on polymorphic behaviour and properties of alternating ethylene-tetrafluoroethylene copolymer. Polymer 36(5):967–973

Kostov G, Nikolov A, Atanassov A (2001) Study of the thermal properties and relaxation transitions in tetrafluoroethene-ethene copolymers. J Appl Polym Sci 81(11):2626–2632

Pucciariello R (1996) Melting behavior of ethylene-tetrafluoroethylene alternating copolymer. J Appl Polym Sci 59(8):1227–1235

Kostov G, Bogdanov B, Nikolov A (1994) Melting and crystallization of tetrafluoroethylene-ethylene copolymers. J Therm Anal Calorim 41(4):925–934

Kung L, Chu B (1995) Viscosity of ethylene tetrafluoroethylene alternating copolymers. Polymer 36(11):2265–2269

Nikolov AT, Dobreva AN, Georgiev DP, Kostov GK (1994) Rheological behaviour of the alternating tetrafluoroethylene-ethylene copolymer. Bulg Chem Commun 27(1):118–124

Wang Z, Tontisakis A, Tuminello W, Buck W, Chu B (1990) Viscosity characterization of an alternating copolymer of ethylene and tetrafluoroethylene. Macromolecules 23(5):1444–1446

Christopher WM (1994) Rheology: principles, measurements, and application. Wiley, New York

Ferry JD (1980) Viscoelastic properties of polymers, 3rd edn. Wiley, New York

Tao Z, Huang J (2003) Observation of melt fracture of polypropylene resins in capillary flow. Polymer 44(3):719–727

Huang Z, Zhang Y, Kotaki M, Ramakrishna S (2003) A review on polymer nanofibers by electrospinning and their applications in nanocomposites. Compos Sci Technol 63(15):2223–2253

Huang J, Tao Z (2003) Melt fracture, melt viscosities, and die swell of polypropylene resin in capillary flow. J Appl Polym Sci 87(10):1587–1594

Kalika DS, Denn MM (1987) Wall slip and extrudate distortion in linear low-density polyethylene. J Rheol 31(8):815–834

Ramamurthy AV (1986) Wall slip in viscous fluids and influence of materials of construction. J Rheol 30(2):337–357

Kurtz SJ (1984) Paper presented at the Advances in Rheology. In: Proceedings of the IX International Congress on Rheology, Universidad Nacional Autonoma de Mexico, Mexico

Chen XY, Yuan WZ, Zhao J, Yang L, Li H, Li L, Zhang Y (2012) Thermal-mechanical stability of ethylene tetrafluoroethylene alternating copolymer, and modification thereof. J Polym Res 19(2):1–6

Denn MM (2001) Extrusion instabilities and wall slip[J]. Annu Rev Fluid Mech 33(1):265–287

Han CD (1976) Rheology in polymer processing. Academic Press, New York

Rosenbaoum E (1998) Rheology and processability of teflon FEP resins for wire coating. The University of British Columbia, Vancouver

Kazatchkov IB, Yip F, Hatzikiriakos SG (2000) The effect of boron nitride on the rheology and processing of polyolefins. Rheol Acta 39(6):583–594

Sentmanat M, Hatzikiriakos SG (2004) Mechanism of gross melt fracture elimination in the extrusion of polyethylenes in the presence of boron nitride. Rheol Acta 43(6):624–633

Rosenbaoum EE, Hatzikiriakos S, Stewart C (1995) Flow implications in the processing of tetrafluoroethylene/hexafluoropropylene copolymers. Int Polym Proc 10(3):204–212

Kurose T, Takahashi T, Nishioka A, Masubuchi Y, Takimoto J-i, Koyama K (2003) The effect of pre-thermal history on shear and uniaxial elongational viscosity of a tetrafluoroethylene/hexafluoropropylene copolymer near the crystal melting transition. Rheol Acta 42(4):338–344

Bagley E (1957) End corrections in the capillary flow of polyethylene. J Appl Phys 28:624

Kim S, Dealy JM (2001) Design of an orifice die to measure entrance pressure drop. J Rheol 45:1413

Ebnesajjad S (2000) Fluoroplastics, vol 2—melt processible fluoropolymers. Plastics Design Library, New York

Haworth B, Gilbert M, Myers D (2005) Melt-state shear flow and elasticity of a thermoplastic fluorosulphonated—PTFE copolymer. J Mater Sci 40(4):955–964

Laun HM (1987) Orientation of macromolecules and elastic deformations in polymer melts. Influence of molecular structure on the reptation of molecules. Prog Colloid Polym Sci 75:111–139

Cogswell FN (1972) Measuring the extensional rheology of polymer melts. J Rheol 16(3):383–403

Cogswell FN (1969) Tensile deformations in molten polymers. Rheol Acta 8(2):187–194

Binding DM, Jones DM (1989) On the interpretation of data from converging flow rheometers. Rheol Acta 28(3):215–222

Binding DM (1988) An approximate analysis for contraction and converging flows. J Non-Newton Fluid 27(2):173–189

Martyn M, Nakason C, Coates P (2000) Measurement of apparent extensional viscosities of polyolefin melts from process contraction flows. J Non-Newton Fluid 92(2–3):203–226

Larson R (1995) The structure and rheology of complex fluids. Oxford University Press, Oxford

Chen K, Shen J, Tang X (2005) Rheological properties of poly (trimethylene terephthalate) in capillary flow. J Appl Polym Sci 97(2):705–709

Huang J, Leong K (2002) Shear viscosity, extensional viscosity, and die swell of polypropylene in capillary flow with pressure dependency. J Appl Polym Sci 84(6):1269–1276

Graessley WW, Glasscock SD, Crawley RL (1970) Die swell in molten polymers. J Rheol 14:519

Chen X-Y, Yuan W, Li H, et al. Rheological study on tetrafluoroethylene/hexafluoropropylene copolymer and its implication for processability[J]. J Appl Polym Sci. doi:10.1002/app.35665

Liang J (2009) Effects of extrusion conditions on melt viscoelasticity during capillary flow of low-density polyethylene. J Thermoplast Compos Mater 22(1):99–110

Thomas DP, Hagan RS (1969) The influence of molecular weight distribution on melt viscosity, melt elasticity, processing behavior and properties of polystyrene. Polym Eng Sci 9(3):164–171

Acknowledgments

We gratefully acknowledge financial supports from the “11th 5-year” National Key Technologies R&D Program of China (no. 2006BAE02A04) and the Shanghai Leading Academic Discipline Project (no. B202).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Chen, XY., Yuan, W.Z., Ai, F. et al. Melt rheological properties of ETFE: an attempt to illuminate the fluorine-substitution effect. Polym. Bull. 69, 375–388 (2012). https://doi.org/10.1007/s00289-012-0759-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-012-0759-1