Abstract

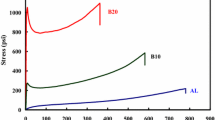

Two kinds of room temperature ionic liquids, [bmim]PF6 (1-butyl-3-methylimidazolium hexafluorophosphate) and [hmim]PF6 (1-hexyl-3-methylimidazolium hexafluorophosphate), were respectively used as plasticizer for PVC paste resin. The mechanical properties, thermal and ultraviolet ray stabilities, and migration characteristics of the PVC paste resin samples were determined by universal testing machine, TG/DTA, and HPLC. The results showed that the tensile strength and elastic modulus decreased, the elongation at break and thermal stability of PVC paste resin membranes were improved with the increasing of [bmim]PF6 or [hmim]PF6 dosages. The immersed time and temperature could accelerate leaching and migration of plasticizers in plasticized PVC paste resin films. Moreover, the effect of solvent environment on migration amount was also studied.

Similar content being viewed by others

References

Rahman M, Brazel CS (2004) The plasticizer market: an assessment of traditional plasticizers and research trends to meet new challenges. Prog Polym Sci 29(12):1223–1248

Saeki Y, Emura T (2002) Technical progresses for PVC production. Prog Polym Sci 27(10):2055–2131

Scott MP, Rahman M, Brazel CS (2003) Application of ionic liquids as low-volatility plasticizers for PMMA. Eur Polym J 39:1947–1953

Ahmed S, Mehmood M, Iqbal R (2010) Influence of dioctyl phthalate (DOP) on the mechanical, optical and thermal properties of formulations for the industrial manufacture of radiation sterilizable medical disposables. Radiat Phys chem 79(3):339–342

Hileman B (2002) FDA suggests replacing DEHP in plastics. Chem Eng News 80(37):6–8

Bierwagen G, Allahar K, Hinderliter B, Simões AMP, Tallman D, Croll S (2008) Ionic liquid enhanced electrochemical characterization of organic coatings. Prog Organ Coat 63:250–259

Xu JM, Jiang JC, Zuo ZY, Li J (2010) Synthesis of tributyl citrate using acid ionic liquid as catalyst. Process Saf Environ Prot 88:28–30

Martinis EM, Olsina RA, Altamirano JC, Wuilloud RG (2009) On-line ionic liquid-based preconcentration system coupled to flame atomic absorption spectrometry for trace cadmium determination in plastic food packaging materials. Talanta 78:857–862

Rahman M, Brazel CS (2006) Ionic liquids: new generation stable plasticizers for poly(vinyl chloride). Polym Degrad Stab 91:3371–3382

Weyershausen B, Lehmann K (2005) Industrial application of ionic liquids as performance additives. Green Chem 7:15–19

Ha JU, Xanthos M (2009) Functionalization of nanoclays with ionic liquids for polypropylene composites. Polym Compos 30(5):534–542

Bermúdez MD, Jiménez AE, Sanes J, Carrión FJ (2009) Ionic liquids as advanced lubricant fluids. Molecules 14:2888–2908

Scott MP, Benton MG, Rahman M, Brazel CS (2003) Plasticizing effects of imidazolium salts in PMMA high-temperature stable flexible engineering materials. In: Rogers RD, Seddon KR (eds) Ionic liquids as green solvents progress and prospects. American Chemical Society Symposium Series 856, Washington, pp 468–477

Park KI, Xanthos M (2009) A study on the degradation of polylactic acid in the presence of phosphonium ionic liquids. Polym Degrad Stab 94:834–844

Goulas AE, Anifantaki KI, Kolioulis DG, Kontominas MG (2000) Migration of di-(2-ethylhexylexyl)adipate plasticizer from food-grade polyvinyl chloride film into hard and soft cheeses. J Dairy Sci 83(8):1712–1718

Hill SS, Shaw BR, Wu AHB (2001) The clinical effects of plasticizers, antioxidants, and other contaminants in medical polyvinylchloride tubing during respiratory and non-respiratory exposure. Clin Chim Acta 304(1–2):1–8

Kaczmarek H, Swiatek M, Kaminska A (2004) Modification of polystyrene and poly(vinyl chloride) for the purpose of obtaining packaging materials degradable in the natural environment. Polym Degrad Stab 83(1):35–45

Matthews G (1996) PVC: production, properties and uses. The Institute of Materials, ISBN 0901716596, Cambridge University Press, London

Odian G (1991) Principles of polymerization, 3rd edn. Wiley, New York

Hill DJT, Lewis DA, O’Donnell JH, Whittaker AK (1998) The crosslinking mechanism in gamma irradiation of polyarylsulfone: evidence for Y-links. Polym Adv Technol 9(1):45–51

Stepnowski P, Muller A, Behrend P, Ranke J, Hoffmann J, Jastorff B (2003) Reversed-phase liquid chromatographic method for the determination of selected room-temperature ionic liquid cations. J Chromatogr A 993:173–178

Park KI, Xanthos M (2007) Ionic liquids as additives for thermoplastics. In: Proc 65th annual technical conference society of plastics engineers, vol 53. The Society of Plastics Engineers, Cincinnati, pp 2659–2662

Okamoto M (2005) Handbook of biodegradable polymeric materials and their applications. American Scientific Publishers, Stevenson Ranch

Acknowledgments

This research was partly supported by the Foundation of Science and Technology Agency of Zhejiang Province (Y4090258, 2010C33004) and Ningbo City (2010A610191), Subject Foundation of Ningbo University (xkl09071) and K. C. Wong Magna Fund in Ningbo University, P. R. China.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hou, L.X., Wang, S. Study on ionic liquid [bmim]PF6 and [hmim]PF6 as plasticizer for PVC paste resin. Polym. Bull. 67, 1273–1283 (2011). https://doi.org/10.1007/s00289-011-0490-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-011-0490-3