Abstract

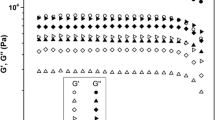

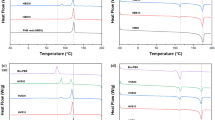

It was demonstrated that the high mixing efficiency of twin screw extruder (TSE) helped to disperse the ethylene–propylene–diene terpolymer (EPDM) domains in polypropylene (PP) matrix, but could not lead to the uniform distribution of EPDM phase with small sizes because of the thermodynamical immiscibility between PP and EPDM. So supercritical carbon dioxide (Sc-CO2) was environmentally and economically introduced to the twin screw extrusion to assist the melt mixing of PP and EPDM. The scanning electron microscopy photographs showed that co-continuous phase morphology was formed to some extent for the PP/EPDM 60/40 blend prepared with Sc-CO2, especially with 2.5 wt% Sc-CO2. This was the one important reason for that the complex viscosity and storage modulus of PP/EPDM 60/40 blend increased with the increase of Sc-CO2 concentration.

Similar content being viewed by others

References

Walker BM (1979) Handbook of thermoplastic elastomers. Van Nostrand Reinhold, New York

Whelan A, Lee HS (1979) Developments in rubber technology. Applied Science, London

Ao YH, Sun SL, Tan ZY, Zhou C, Zhang HX (2006) Compatibilization of PP/EPDM blends by grafting acrylic acid to polypropylene and epoxidizing the diene in EPDM. J Appl Polym Sci 102:3949–3954

Yazdani H, Morshedian J, Khonakdar HA (2006) Effect of maleated polypropylene and impact modifiers on the morphology and mechanical properties of PP/Mica composites. Polym Compos 27:614–620

Lopez Manchado MA, Biagiotti J, Kenny JM (2001) Rheological behavior and processability of polypropylene blends with rubber ethylene propylene diene terpolymer. J Appl Polym Sci 81:1–10

Kim BC, Hwang SS, Lim KY, Yoon KJ (2000) Toughening of PP/EPDM blend by compatibilization. J Appl Polym Sci 78:1267–1274

Shariatpanahi H, Nazokdast H, Dabir B, Sadaghiani K, Hemmati M (2002) Relationship between interfacial tension and dispersed-phase particle size in polymer blends. I. PP/EPDM. J Appl Polym Sci 86:3148–3159

Purnima D, Maiti SN, Gupta AK (2006) Interfacial adhesion through maleic anhydride grafting of EPDM in PP/EPDM blend. J Appl Polym Sci 102:5528–5532

Feng W, Isayev AI (2004) In situ compatibilization of PP/EPDM blends during ultrasound aided extrusion. Polymer 45:1207–1216

Chen Y, Li H (2004) Effect of ultrasound on extrusion of PP/EPDM blends: structure and mechanical properties. Polym Eng Sci 44:1509–1513

Chen Y, Li H (2005) Phase morphology evolution and compatibility improvement of PP/EPDM by ultrasound irradiation. Polymer 46:7707–7714

Yang H, Zhang XQ, Qu C, Li B, Zhang LJ, Zhang Q, Fu Q (2007) Largely improved toughness of PP/EPDM blends by adding nano-SiO2 particles. Polymer 48:860–869

Arroyoa M, Zitzumbob R, Avalosc F (2000) Composites based on PP/EPDM blends and aramid short fibres. Morphology/behaviour relationship. Polymer 41:6351–6359

Wang X, Sun J, Huang R (2006) Influence of the compounding route on the properties of polypropylene/nano-CaCO3/ethylene–propylene–diene terpolymer tercomponent composites. J Appl Polym Sci 99:2268–2272

Lopez Manchado MA, Arroyo M, Biagiotti J, Kenny JM (2003) Enhancement of mechanical properties and interfacial adhesion of PP/EPDM/flax fiber composites using maleic anhydride as a compatibilizer. J Appl Polym Sci 90:2170–2178

Liang JZ, Li RKY, Tjong SC (2000) Impact fracture behavior of PP/EPDM/glass bead ternary composites. Polym Eng Sci 40:2105–2111

Lee M, Tzoganakis C, Park CB (1998) Extrusion of PE/PS blends with supercritical carbon dioxide. Polym Eng Sci 38:1112–1120

Elkovitch MD, Lee LJ, Tomasko DL (1999) Supercritical carbon dioxide assisted blending of polystyrene and poly(methyl methacrylate). Polym Eng Sci 39:2075–2084

Tomasko DL, Li H, Liu D, Han X, Wingert MJ, Lee LJ, Koelling KW (2003) A review of CO2 applications in the processing of polymers. Ind Eng Chem Res 42:6431–6456

Tomasko DL, Han X, Liu D, Gao W (2003) Supercritical fluid applications in polymer nanocomposites. Curr Opin Solid State Mater Sci 7:407–412

Zhao Y, Huang HX (2008) Dynamic rheology and microstructure of polypropylene/clay nanocomposites prepared under Sc-CO2 by melt compounding. Polym Test 27:129–134

Favis BD, Chalifoux JP (1987) Effect of viscosity ratio on the morphology of polypropylene/polycarbonate blends during processing. Polym Eng Sci 27:1591–1600

Qian R (2002) Perspectives on the macromolecular condensed state. World Scientific Publishing Co., Singapore

Acknowledgments

The authors acknowledge the financial support provided by the contract grant sponsor—the National Natural Science Foundation of China (contract grant number: 10672061) and Teaching and Research Award Program for Outstanding Young Teachers in Higher Education Institutions of Ministry of Education, People’s Republic of China.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhao, Y., Huang, HX. & Chen, YK. Dynamic rheology–morphology relationship of PP/EPDM blends prepared by melt mixing under Sc-CO2 . Polym. Bull. 64, 291–302 (2010). https://doi.org/10.1007/s00289-009-0187-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-009-0187-z