Abstract

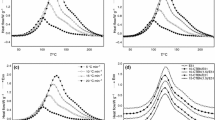

The curing behaviour of epoxy resins modified with reactive liquid rubber, using a novolac resin as a hardner was studied by means of differential scanning calorimetry in isothermal (100, 130 and 150 °C) and non-isothermal conditions (2, 5, 10 and 15 °C min-1). The influence of carboxyl- (CTBN) and epoxy- (ETBN) terminated butadiene-acrylonitrile copolymers on the kinetic parameters and glass transition temperature (Tg) of cured epoxy systems was determined. The effect of grinded bituminous coal as an organic filler into epoxy network was also investigated. The carboxyl-end groups strongly enhanced the curing rate, in contrast to the epoxy-terminated rubber (ETBN) that had only a minor effect on the curing reactions. The presence of coal accelerated curing in its early stage. The Tg of completely cured epoxy was practically unaffected by the presence of carbon filler and reactive rubbers and was equal about 132 °C. The apparent curing activation energies were determined. A smaller activation energy was observed only for CTBN/epoxy/novolac system. The effect of reactive rubber and coal on the Charpy impact resistance of cured epoxy systems was also discussed.

Similar content being viewed by others

References

May CA (1988) Epoxy Resins. Chemistry and technology, M Dekker (Ed). NY and Basel

Ellis B (1993) Chemistry and Technology of Epoxy Resins. Chapman & Hall, London

Van Krevelen DW (1993) Property of polymers, their correlation with chemical structure; their numerical estimation and prediction from additive group contributions. Elsevier, Amsterdam-Lausanne, New York, Oxford, Shannon, Tokyo

Barton JM (1985) in Dusek K (ed) Epoxy Resins and Composites I. Advances in Polymer Science, vol 72, Springer-Verlag, Berlin, pp 112–154

Czub P, Bończa-Tomaszewski Z, Penczek P, Pielichowski J (2002) Chemia i technologia żywic epoksydowych. WNT, Warszawa

Gualpa MC, Riccardi CC, Vazquez A (1998) Polymer 39:2247

Shalin RE (1995) Polymer Matrix Composites. Chapman & Hall, London

Riew CK, Kinloch AJ (1993) Toughened Plastics I. Science and Engineering. American Chemical Society, Washington, DC

Frigione ME, Mascia L, Acierno D (1999) Eur Polym J 31:1021

Chen D, Pascault JP, Sautereau H (1994) Polym Int 33:263

Chen D, Pascault JP, Bertch RJ, Drake RS, Siebert AR (1994) J Appl Polym Sci 51:1959

Ratna D (2001) Polymer 42:4209

Martinez I, Martin MD, Eceiza A, Oyanguren P, Mondragon I (2000) Polymer 41:1027

Bagheri R, Williams MA, Pearson RA (1997) Polym Eng Sci 37:5

Celikbilek C, Akovali G, Kaynak C (2004) Polym Bull 51:429

Shechter L, Wynstra J (1956) Ind Eng Chem 48:86

Prime RB (1981) Thermosets. In: Turi EA (ed) Thermal Characterization of Polymeric Materials. Academic Press Inc, London, pp 435–569

Jenninger W, Schawe JEK, Alig I (2000) Polymer 41:1577

Wise CW, Cook WD, Goodwin AA (2000) Polymer 41:4625

Verchere D, Sautereau H, Pascault JP, Moschiar SM, Riccardi CC, Williams RJJ (1990) J Appl Polym Sci 41:467

Lu M, Shim MS, Kim S (1999) Polym Eng Sci 39:274

Hepburn DM, Kemp IJ, Cooper JM (2000) Polym Degrad Stab 70:245

Sadhan CJ, Sachin J (2001) Polymer 42:6897

Lee J, Yee AF (2000) Polymer 42:577

Maazouz A, Sautereau H, Gerard JF (2000) J Appl Polym Sci 50:615

Kurzeja L (1996) in Proceedings of the European Carbon Conference, Newcastle, GB, vol 1, 94

Kurzeja L, Szeluga U, Galy J, Sautereau H, Issartel N (2003) Macromol Symp 194:169

Szeluga U, Kurzeja L, Galina H (2006) Polimery (Warsaw) 51:809

Szeluga U, Kurzeja L, Galina H (2005) Annals of the Polish Chemical Society 1:455

Van Krevelen DW (1993) Coal. Topology, Physics, Chemistry, Constitution. Elsevier (3rd ed)

Matejka L, Pokorny S, Dusek K (1982) Polym Bull 7:123

Kissinger HE (1957) Anal Chem 29:1702

Ozawa T (1965) Bull Chem Soc Jpn 38:1881

Flynn JH (1983) J Therm Anal 27:95

Kamal MR (1974) Polym Eng Sci 14:2

Riccardi CC, Dupuy J, Williams RJJ (1999) J Polym Sci - Polym Phys 37:2799

Lopez J, Lopez-Bueno I, Nogueira P, Ramirez C, Abad MJ, Barral L, Cano J (2001) Polymer 42:1669

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Szeluga, U., Kurzeja, L. & Galina, H. Curing of epoxy/novolac system modified with reactive liquid rubber and carbon filler . Polym. Bull. 60, 555–567 (2008). https://doi.org/10.1007/s00289-008-0889-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-008-0889-7