Abstract

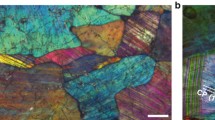

Synthesized mineral powders with particle size of <100 nm are vacuum sintered to obtain highly dense and fine-grained polycrystalline mantle composites: single phase aggregates of forsterite (iron-free), olivine (iron containing), enstatite and diopside; two-phase composites of forsterite + spinel and forsterite + periclase; and, three-phase composites of forsterite + enstatite + diopside. Nano-sized powders of colloidal SiO2 and highly dispersed Mg(OH)2 with particle size of ≤50 nm are used as chemical sources for MgO and SiO2, which are common components for all of the aggregates. These powders are mixed with powders of CaCO3, MgAl2O4, and Fe(CO2CH3)2 to introduce mineral phases of diopside, spinel, and olivine to the aggregates, respectively. To synthesize highly dense composites through pressureless sintering, we find that calcined powders should be composed of particles that have: (1) fully or partially reacted to the desired minerals, (2) a size of <100 nm and (3) less propensity to coalesce. Such calcined powders are cold isostatically pressed and then vacuum sintered. The temperature and duration of the sintering process are tuned to achieve a balance between high density and fine grain size. Highly dense (i.e., porosity ≤1 vol%) polycrystalline mantle mineral composites with grain size of 0.3–1.1 μm are successfully synthesized with this method.

Similar content being viewed by others

References

Burlicht JM, Beeman ML, Riley BB, Kohlstedt DL (1991) Low temperature synthesis of olivine and forsterite facilitated by hydrogen peroxide. Chem Mater 3:692–698

Carter CB, Norton MG (2007) Ceramic materials. Springer, Berlin

Cooper RF (1990) Differential stress-induced melt migration: an experimental approach. J Geophys Res 95:6979–6992

Dohmen R, Becker H-W, Meißner E, Thomas E, Chakraborty S (2002) Production of silicate thin films using pulsed laser deposition (PLD) and applications to studies in mineral kinetics. Eur J Miner 14:1155–1168

Evans AG (1978) Microfracture from thermal expansion anisotropy-I. Single phase systems. Acta Metall 26:1845–1853

Gribb TT, Cooper RF (1998) Low frequency shear attenuation in polycrystalline olivine: grain boundary diffusion and the physical significance of the Andrade model for viscoelastic rheology. J Geophys Res 103:27267–27279. doi:10.1029/98JB02786

Hiraga T, Kohlstedt DL (2007) Equilibrium interface segregation in the diopside-forsterite system I: analytical techniques, thermodynamics, and segregation characteristics. Geochim Cosmochim Acta 71:1266–1280

Hiraga T, Anderson IM, Zimmerman ME, Mei S, Kohlstedt DL (2002) Structure and chemistry of grain boundaries in deformed, olivine + basalt and partially molten lherzolite aggregates: evidence of melt-free grain boundaries. Contrib Miner Petrol 144:163–175

Irifune T, Higo Y, Inoue T, Kono Y, Ohfuji H, Funakoshi K (2008) Sound velocities of majorite garnet and the composition of the mantle transition region. Nature 451:814–817

Jackson JM, Sinogeikin TV, Carpenter MA, Bass JD (2004) Novel phase transition in orthoenstatite. Am Miner 89:239–245

Lee DW, Kingery WD (1960) Radiation energy transfer and thermal conductivity of ceramic oxides. J Am Ceram Soc 43:594–607

Li J, Ye Y (2006) Densification and grain growth of Al2O3 nanoceramics during pressureless sintering. J Am Ceram Soc 89:139–143

Mazaheri M, Simchi A, Golestani-Fard F (2008) Densification and grain growth of nanocrystalline 3Y-TZP during two-step sintering. J Eur Ceram Soc 28:2933–2939

McDonnell RD, Peach CJ, Spiers CJ (1999) Flow behavior of fine-grained synthetic dunite in the presence of 0.5 wt% H2O. J Geophys Res 104:1785–17823

McDonnell RD, Spiers CJ, Peach CJ (2002) Fabrication of dense forsterite-enstatite polycrystals for experimental studies. Phys Chem Miner 29:19–31

Saito N, Matsuda S, Ikegami T (1998) Fabrication of transparent yttria ceramics at low temperature using carbonate-derived powder. J Am Ceram Soc 81:2023–2028

Sano S, Saito N, Matsuda S, Ohashi N, Haneda H (2006) Synthesis of high density and transparent forsterite ceramics using nano-sized precursors and their dielectric properties. J Am Ceram Soc 89:568–574

Acknowledgments

A portion of this work was conducted at Center for Nano Lithography and Analysis, the University of Tokyo, supported by the Ministry of Education, Culture, Sports, Science and Technology (MEXT), Japan. Technical supports from S. Ohtsuka, K. Ibe, M. Uchida, S. Matsumoto, I. Sakaguchi and A. Yasuda are greatly appreciated. The authors thank Y. Nishihara, N. Tomioka and T. Kuribayashi for helpful comments. Scientific and editorial comments from C. McCarthy were valuable. This research was supported by the JSPS through Grant-in-Aid for Young Scientists (A) 20684024 and by the Earthquake Research Institute cooperative research program to T.H.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Koizumi, S., Hiraga, T., Tachibana, C. et al. Synthesis of highly dense and fine-grained aggregates of mantle composites by vacuum sintering of nano-sized mineral powders. Phys Chem Minerals 37, 505–518 (2010). https://doi.org/10.1007/s00269-009-0350-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00269-009-0350-y