Abstract

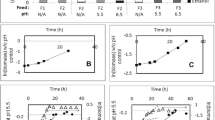

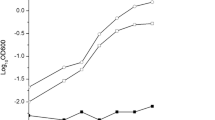

A new screening method was developed and established to find high-performance bacteria for the conversion of crude glycerol to 1,3-propanediol. Three soil samples from palm oil-rich habitats were investigated using crude glycerol of a German biodiesel plant. Nine promising 1,3-propanediol producers could be found. Because of a special pH buffer system, a fast evaluation on microscale and high 1,3-propanediol concentrations up to 40 g L−1 could be achieved. Three strains demonstrated very high product tolerance and were identified as Clostridium butyricum. Two strains, AKR91b and AKR102a, grew and produced 1,3-propanediol in the presence of 60 g L−1 initial 1,3-propanediol, the strain AKR92a even in the presence of 77 g L−1 1,3-propanediol. The strains AKR91b and AKR102a tolerated up to 150 g L−1 crude glycerol and produced 80% of the 1,3-propanediol attained from pure glycerol of the same concentration. Further criteria for the choice of a production strain were the pathogenicity (risk class), ability to grow on low-cost media, e.g., with less yeast extract, and robustness, e.g., process stability after several bioconversions. Overall, the strain C. butyricum AKR102a was chosen for further process optimization and scale-up due to its high productivity and high final concentration in a pH-regulated bioreactor.

Similar content being viewed by others

References

Abbad-Andaloussi S, Manginotdurr C, Amine J, Petitdemange E, Petitdemange H (1995) Isolation and characterization of Clostridium butyricum DSM 5431 mutants with increased resistance to 1,3-propanediol and altered production of acids. Appl Environ Microbiol 61:4413–4417

Barbirato F, Camarasaclaret C, Grivet JP, Bories A (1995) Glycerol fermentation by a new 1,3-propanediol-producing microorganism—Enterobacter agglomerans. Appl Microbiol Biotechnol 43:786–793

Biebl H, Marten S, Hippe H, Deckwer WD (1992) Glycerol conversion to 1,3-propanediol by newly isolated clostridia. Appl Microbiol Biotechnol 36:592–597

Colin T, Bories A, Moulin G (2000) Inhibition of Clostridium butyricum by 1,3-propanediol and diols during glycerol fermentation. Appl Microbiol Biotechnol 54:201–205

Colin T, Bories A, Lavigne C, Moulin G (2001) Effects of acetate and butyrate during glycerol fermentation by Clostridium butyricum. Curr Microbiol 43:238–243

Daniel R, Boenigk R, Gottschalk G (1995) Purification of 1,3-propanediol dehydrogenase from Citrobacter freundii and cloning, sequencing, and overexpression of the corresponding gene in Escherichia coli. J Bacteriol 177:2151–2156

DSMZ (2011) German collection of microorganisms and cell cultures, list of media. At http://www.dsmz.de/microorganisms/media_list.php. Accessed 19 Jul 2011

Forage RG, Foster MA (1982) Glycerol fermentation in Klebsiella pneumoniae—functions of the coenzyme-B12-dependent glycerol and diol dehydratases. J Bacteriol 149:413–419

Forsberg CW (1987) Production of 1,3-propanediol from glycerol by Clostridium acetobutylicum and other Clostridium species. Appl Environ Microbiol 53:639–643

Freund A (1881) Uber die Bildung und Darstellung von Trimethylenalkohol aus Glycerin. Berichte der Deutschen Chemischen Gesellschaft Berlin 10:636–641

Gonzalez-Pajuelo M, Andrade JC, Vasconcelos I (2004) Production of 1,3-propanediol by Clostridium butyricum VPI 3266 using a synthetic medium and raw glycerol. J Ind Microbiol Biotechnol 31:442–446

Hao J, Lin R, Zheng Z, Liu H, Liu D (2008) Isolation and characterization of microorganisms able to produce 1,3-propanediol under aerobic conditions. World J Microbiol Biotechnol 24:1731–1740

Hirschmann S, Baganz K, Koschik I, Vorlop KD (2005) Development of an integrated bioconversion process for the production of 1,3-propanediol from raw glycerol waters. Landbauforschung Volkenrode 55:261–267

Homann T, Tag C, Biebl H, Deckwer WD, Schink B (1990) Fermentation of glycerol to 1,3-propanediol by Klebsiella and Citrobacter strains. Appl Microbiol Biotechnol 33:121–126

Luthi-Peng Q, Dileme FB, Puhan Z (2002) Effect of glucose on glycerol bioconversion by Lactobacillus reuteri. Appl Microbiol Biotechnol 59:289–296

Menzel K, Zeng AP, Deckwer WD (1997) High concentration and productivity of 1,3-propanediol from continuous fermentation of glycerol by Klebsiella pneumoniae. Enzyme Microb Technol 20:82–86

Moon C, Ahn JH, Kim SW, Sang BI, Um Y (2009) Effect of biodiesel-derived raw glycerol on 1,3-propanediol production by different microorganisms. Appl Biochem Biotechnol 161:502–510

Otte B, Grunwaldt E, Mahmoud O, Jennewein S (2009) Genome shuffling of Clostridium diolis DSM 15410 for improved 1,3-propanediol production. Appl Environ Microbiol 75:7610–7616

Petitdemange E, Durr C, Andaloussi SA, Raval G (1995) Fermentation of raw glycerol to 1,3-propanediol by new strains of Clostridium butyricum. J Ind Microbiol 15:498–502

Petrova P, Petrov K, Beschkov V (2009) Production of 1,3-propanediol from glycerol by newly isolated strains of Klebsiella pneumoniae. Comptes Rendus de l Academie Bulgare des Sciences 62:233–242

Pflugmacher U, Gottschalk G (1994) Development of an immobilized cell reactor for the production of 1,3-propanediol by Citrobacter freundii. Appl Microbiol Biotechnol 41:313–316

Rehman A, Saman WRG, Nomura N, Sato S, Matsumura M (2008) Pre-treatment and utilization of raw glycerol from sunflower oil biodiesel for growth and 1,3-propanediol production by Clostridium butyricum. J Chem Technol Biotechnol 83:1072–1080

Reimann A, Abbad-Andaloussi S, Biebl H, Petitdemange H (1998) 1,3-Propanediol formation with product-tolerant mutants of Clostridium butyricum DSM 5431 in continuous culture: productivity, carbon and electron flow. J Appl Microbiol 84:1125–1130

Saxena RK, Anand P, Saran S, Isar J (2009) Microbial production of 1,3-propanediol: recent developments and emerging opportunities. Biotechnol Adv 27:895–913

Schutz H, Radler F (1984) Anaerobic reduction of glycerol to propanediol-1.3 by Lactobacillus brevis and Lactobacillus buchneri. Syst Appl Microbiol 5:169–178

Wilkens E, Ringel AK, Hortig D, Willke T, Vorlop KD (2011) High-level production of 1,3-propanediol from crude glycerol by Clostridium butyricum AKR102a. Appl Microbiol Biotechnol. doi:10.1007/s00253-011-3595-6

Willke T, Vorlop K (2008) Biotransformation of glycerol into 1,3-propanediol. Eur J Lipid Sci Technol 110:831–840

Wittlich P (2001) Biotechnologische Herstellung von 1,3-Propandiol mit immobilisierten Zellen von Clostridium butyricum NRRL 1024 und thermophilen Mikroorgansimen. Dissertation, TU Braunschweig

Wittlich P, Themann A, Vorlop KD (2001) Conversion of glycerol to 1,3-propanediol by a newly isolated thermophilic strain. Biotechnol Lett 23:463–466

Yang G, Tian JS, Li JL (2007) Fermentation of 1,3-propanediol by a lactate deficient mutant of Klebsiella oxytoca under microaerobic conditions. Appl Microbiol Biotechnol 73:1017–1024

Yazdani SS, Gonzalez R (2007) Anaerobic fermentation of glycerol: a path to economic viability for the biofuels industry. Curr Opin Biotechnol 18:213–219

Zeng AP (1996) Pathway and kinetic analysis of 1,3-propanediol production from glycerol fermentation by Clostridium butyricum. Bioprocess Engineering 14:169–175

Zeng AP, Biebl H, Schlieker H, Deckwer WD (1993) Pathway analysis of glycerol fermentation by Klebsiella pneumoniae—regulation of reducing equivalent balance and product formation. Enzym Microb Technol 15:770–779

Zeng AP, Ross A, Biebl H, Tag C, Günzel B, Deckwer WD (1994) Multiple product inhibition and growth modeling of Clostridium butyricum and Klebsiella pneumoniae in glycerol fermentation. Biotechnol Bioeng 44:902–911

Zhang GL, Ma BB, Xu XL, Li C, Wang LW (2007) Fast conversion of glycerol to 1,3-propanediol by a new strain of Klebsiella pneumoniae. Biochem Eng J 37:256–260

Acknowledgments

This project was funded by the German Federal Ministry of Education and Research (BMBF) (IG-Biotech 0315026E).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ringel, A.K., Wilkens, E., Hortig, D. et al. An improved screening method for microorganisms able to convert crude glycerol to 1,3-propanediol and to tolerate high product concentrations. Appl Microbiol Biotechnol 93, 1049–1056 (2012). https://doi.org/10.1007/s00253-011-3594-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-011-3594-7