Abstract

Using the anode effluent to compensate the alkalinization in a bio-cathode has recently been proposed as a way to operate a microbial fuel cell (MFC) in a continuous and pH neutral way. In this research, we successfully demonstrated that the operation of a MFC without any pH adjustments is possible by completing the liquid loop over cathode and anode. During the complete loop operation, a stable current production of 23.2 ± 2.5 A m−3 MFC was obtained, even in the presence of 3.2–5.2 mg O2 L−1 in the anode. The use of current collectors and subdivided electrical circuitries for relative large 2.5-L-scale MFCs resulted in ohmic cell resistances in the order of 1.4–1.7 mΩ m3 MFC, which were comparable to values of ten times smaller MFCs. Nevertheless, the bio-cathode activity still needs to be improved significantly with a factor 10–50 in order achieve desirable current densities of 1,000 A m−3 MFC.

Similar content being viewed by others

References

Bond DR, Lovley DR (2003) Electricity production by Geobacter sulfurreducens attached to electrodes. Appl Environ Microbiol 69:1548–1555

Clauwaert P, Rabaey K, Aelterman P, DeSchamphelaire L, Pham TH, Boeckx P, Boon N, Verstraete W (2007a) Biological denitrification in microbial fuel cells. Environ Sci Technol 41:3354–3360

Clauwaert P, Van der Ha D, Boon N, Verbeken K, Verhaege M, Rabaey K, Verstraete W (2007b) Open air biocathode enables effective electricity generation with microbial fuel cells. Environ Sci Technol 41:7564–7569

Clauwaert P, Aelterman P, Pham TH, De Schamphelaire L, Carballa M, Rabaey K, Verstraete W (2008) Minimizing losses in bio-electrochemical systems: the road to applications. Appl Microbiol Biotechnol 79:901–913

Freguia S, Rabaey K, Yuan ZG, Keller J (2007) Electron and carbon balances in microbial fuel cells reveal temporary bacterial storage behavior during electricity generation. Environ Sci Technol 41:2915–2921

Freguia S, Rabaey K, Yuan ZG, Keller J (2008) Sequential anode–cathode configuration improves cathodic oxygen reduction and effluent quality of microbial fuel cells. Water Res 42:1387–1396

Hong L, Shaoan C, Liping H, Logan BE (2008) Scale-up of membrane-free single-chamber microbial fuel cells. J Power Sources 179:274–279

Logan BE, Hamelers B, Rozendal R, Schroder U, Keller J, Freguia S, Aelterman P, Verstraete W, Rabaey K (2006) Microbial fuel cells: methodology and technology. Environ Sci Technol 40:5181–5192

Logan BE, Cheng S, Watson V, Estadt G (2007) Graphite fiber brush anodes for increased power production in air-cathode microbial fuel cells. Environ Sci Technol 41:3341–3346

Nevin KP, Richter H, Covalla SF, Johnson JP, Woodard TL, Orloff AL, Jia H, Zhang M, Lovley DR (2008) Power output and coulombic efficiencies from biofilms of Geobacter sulfurreducens comparable to mixed community microbial fuel cells. Environ Microbiol 10(10):2505–2514

Pham H, Boon N, Aelterman P, Clauwaert P, De Schamphelaire L, van Oostveldt P, Verbeken K, Rabaey K, Verstraete W (2008) High shear enrichment improves the performance of the anodophilic microbial consortium in a microbial fuel cell. Microb Biotechnol 1(6):487–496

Rabaey K, Clauwaert P, Aelterman P, Verstraete W (2005) Tubular microbial fuel cells for efficient electricity generation. Environ Sci Technol 39:8077–8082

Rabaey K, Read ST, Clauwaert P, Freguia S, Bond PL, Blackall LL, Keller J (2008) Cathodic oxygen reduction catalyzed by bacteria in microbial fuel cells. Isme J 2:519–527

Rozendal RA, Hamelers HVM, Buisman CJN (2006) Effects of membrane cation transport on pH and microbial fuel cell performance. Environ Sci Technol 40:5206–5211

Rozendal RA, Hamelers HVM, Rabaey K, Keller J, Buisman CJN (2008a) Towards practical implementation of bioelectrochemical wastewater treatment. Trends Biotechnol 26:450–459

Rozendal RA, Sleutels T, Hamelers HVM, Buisman CJN (2008b) Effect of the type of ion exchange membrane on performance, ion transport, and pH in biocatalyzed electrolysis of wastewater. Water Sci Technol 57:1757–1762

Ter Heijne A, Hamelers HVM, Buisman CJN (2007) Microbial fuel cell operation with continuous biological ferrous iron oxidation of the catholyte. Environ Sci Technol 41:4130–4134

Zhao F, Harnisch F, Schroder U, Scholz F, Bogdanoff P, Herrmann I (2005) Application of pyrolysed iron(II) phthalocyanine and CoTMPP based oxygen reduction catalysts as cathode materials in microbial fuel cells. Electrochem Commun 7:1405–1410

Acknowledgements

The useful comments of Gabriele Gross and David van der Ha are kindly acknowledged. This research was funded by a Ph.D. grant (IWT grant 53305) of the Institute for the Promotion of Innovation through Science and Technology in Flanders (IWT-Vlaanderen) and the European Commission (Neptune project, contract no. 036845, FP6-2005-Global-4, SUSTDEV-2005-3.II.3.2).

Author information

Authors and Affiliations

Corresponding author

Electronic Supplementary Material

Below is the link to the electronic supplementary material

Figure S1

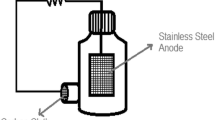

Overview of the construction of the microbial fuel cells. I: The empty anode frame of the three MFCs; II: nine subanodes are introduced; III: a cation exchange membrane separates the anode from the cathode; IV: a picture of the reactor (in panel I, a: anode contact, b: inlet anode, c: outlet anode, d: rubber sheet; in panel II, e: stainless steel frame filled with granular graphite, f: perforated rubber sheet to avoid electrical contact; in panel III, g: cation exchange membrane, h: carbon felt with a stainless steel current collector, i: outlets cathode effluent; in panel IV, j: liquid vessel) (DOC 802 KB)

Rights and permissions

About this article

Cite this article

Clauwaert, P., Mulenga, S., Aelterman, P. et al. Litre-scale microbial fuel cells operated in a complete loop. Appl Microbiol Biotechnol 83, 241–247 (2009). https://doi.org/10.1007/s00253-009-1876-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-009-1876-0