Abstract

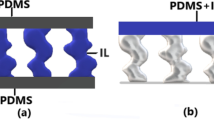

Pervaporation proved to be one of the best methods to remove solvents out of a solvent producing Clostridium acetobutylicum culture. By using an ionic liquid (IL)-polydimethylsiloxane (PDMS) ultrafiltration membrane (pore size 60 nm), we could guarantee high stability and selectivity during all measurements carried out at 37°C. Overall solvent productivity of fermentation connected with continuous product removal by pervaporation was 2.34 g l−1 h−1. The supported ionic liquid membrane (SILM) was impregnated with 15 wt% of a novel ionic liquid (tetrapropylammonium tetracyano-borate) and 85 wt% of polydimethylsiloxane. Pervaporation, accomplished with the optimized SILM, led to stable and efficient removal of the solvents butan-1-ol and acetone out of a C. acetobutylicum culture. By pervaporation through SILM, we removed more butan-1-ol than C. acetobutylicum was able to produce. Therefore, we added an extra dose of butan-1-ol to run fermentation on limiting values where the bacteria would still be able to survive its lethal concentration (15.82 g/l). After pervaporation was switched off, the bacteria died from high concentration of butan-1-ol, which they produced.

Similar content being viewed by others

References

Bahl H, Gottschalk G (1984) Parameters affecting solvent production by Clostridium acetobutylicum in continuous culture. Biotechnol Bioeng Symp 14:215–223

Bahl H, Andersch W, Braun K, Gottschalk G (1982a) Effect of pH and butyrate concentration on the production of acetone and butanol by Clostridium acetobutylicum grown in continuous culture. Eur J Appl Microbiol Biotechnol 14:17–20

Bahl H, Andersch W, Gottschalk G (1982b) Continuous production of acetone and butan-1-ol by Clostridium acetobutylicum in a two-stage phosphate limited chemostat. Eur J Appl Microbiol Biotechnol 15:201–205

Bahl HP, Dürre P (2001) Clostridia. Biotechnology and medical applications. Wiley, Weinheim, pp 125–168

Benton MG, Brazel CS (2002) Comparison of kinetics for solution polymerization of poly(methyl methacrylate) in green ionic liquid solvents versus traditional volatile solvents. Polym Preprints 43:881–885

Cornillot E, Nair EV, Papoutsakis ET, Soucaille P (1997) The genes of butan-1-ol and acetone formation in Clostridium acetobutylicum ATCC 824 reside on a large plasmid whose loss leads to degeneration of the strain. J Bacteriol 179:5442–5447

Dai S et al (2003) Technical summaries on ionic liquids in chemical processing, pp 11–15

Duppont J, Souza RF, Suarez PAZ (2002) Ionic liquid (molten salt) phase organometallic catalysis. Chem Rev 102:3667–3692

Dürre P (1998) New insights and novel developments in clostridial acetone/butan-1-ol/isopropanol fermentation. Appl Microbiol Biotechnol 49:639–648

Dürre P (eds) (2005a) Handbook on clostridia. Taylor & Francis Group, London

Dürre P (2005b) Formation of solvents in Clostridia. In: Dürre P (ed) Handbook on Clostridia. Taylor & Francis Group, London, pp 671–693

Fischer RJ, Oehmcke S, Meyer U, Mix M, Schwarz K, Fiedler T, Bahl H (2006) Transcription of the pst operon of Clostridium acetobutylicum is dependent on phosphate [1] concentration and pH. J Bacteriol 188:5469–5478

Harrison S, Mackenzie S, Haddleton DM (2002) Pulsed laser polymerization of methyl methacrylate in ionic liquids. Polym Prepr 43(2):883–884

Heintz A (2005) Recent developments in thermodynamics and thermophysics of non-aqueous mixtures containing ionic liquids. J Chem Thermodyn 37:525–535

Holbrey JD, Seddon KR (1999) The phase behaviour of 1-alkyl-3-methylimidazolium tetrafluoroborates; ionic liquids and ionic liquid crystals. J Chem Soc Dalton Trans, pp 2133–2139

Hong K et al (2002) Conventional free radical polymerization in room temperature ionic liquids: a green approach to commodity polymers with practical advantages. Chem Commun 13:1368–1369

Izák P, Mateus NMM, Afonso CAM, Crespo JG (2005) Enhanced esterification conversion in a room temperature ionic liquid by integrated water removal with pervaporation. Separation and Purification Technology 41:141–145

Izák P, Köckerling M, Kragl U (2006) Stability and selectivity of a multiphase membrane, consisting of a dimethylpolysiloxane on ionic liquid, used in the separation of solutes from aqueous mixtures by pervaporation. Green Chem 8:947–948

Izák P, Ruth W, Dyson P, Kragl U (2008) Selective removal of acetone and butan-1-ol from water with supported ionic liquid—polydimethylsiloxane membrane by pervaporation. Chem Eng J CEJ-5464

Liu F, Liu L, Feng X (2005) Separation of acetone–butanol–ethanol (ABE) from dilute aqueous solutions by pervaporation. Separation and Purification Technology 42(3):273–282

Pretti C, Chiappe C, Pieraccini D, Gregori M, Abramo F, Monni G, Intorre L (2006) Acute toxicity of ionic liquids to the zebrafish (Danio rerio). Green Chem 3:238–240

Qureshi N, Maddox IS (2005) Reduction in butan-1-ol inhibition by persraction: utilization of concentrated lactose/whey permeate by Clostridium acetobutylicum to enhance butan-1-ol fermentation economics. Food Bioprod Process 83:43–52

Rose AH (1961) Industrial microbiology. Butterworths, London, pp 160–166

Soni BK, Soucaille P, Goma G (1987) Continuous acetone–butanol fermentation: a global approach for the improvement in the solvent productivity in synthetic medium. Appl Microbiol Biotechnol 25:317–321

Van Rantwijk F, Sheldon R (2007) Biocatalysis in ionic liquids. Chem Rev 107:2757–2785

Walker AJ, Bruce NC (2004) Cofactor-dependent enzyme catalysis in functionalized ionic solvents. Chem Commun 22:2570–2571

Wasserscheid P, Keim W (2000) Ionic liquids—new “solutions” for transition metal catalysis. Angew Chem Int Ed 39(21):3772–3789

Welton T (1999) Room-temperature ionic liquids. Solvents for synthesis and catalysis. Chem Rev 99:2071–2083

Woods DR (1993) The Clostridia and biotechnology. Butterworth-Heinemann, London

Yu J, Li H, Liu H (2006) Recovery of acetic acid over water by pervaporation with a combination of hydrophobic ionic liquids. Chem Eng Commun 193(11):1422–1430

Zilversmit DB, Davis AK (1950) Microdetermination of plasma phospholipids by trichloroacetic acid precipitation. J Lab Clin Med 35:155–160

Acknowledgement

This research was supported by Marie Curie Intra-European and Marie Curie Reintegration Fellowships within the 6th European Community Framework Programme. P. Izák is also grateful to Purkyne Fellowship from the Academy of Science of the Czech Republic and grant No. 104/08/0600 from Czech Science Foundation. Part of the Work was financially supported by the Fonds der Chemischen Industrie.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Izák, P., Schwarz, K., Ruth, W. et al. Increased productivity of Clostridium acetobutylicum fermentation of acetone, butanol, and ethanol by pervaporation through supported ionic liquid membrane. Appl Microbiol Biotechnol 78, 597–602 (2008). https://doi.org/10.1007/s00253-008-1354-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-008-1354-0