Abstract

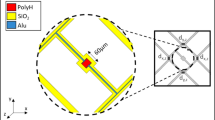

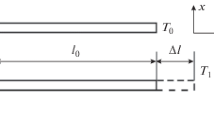

A kind of micromachined convective accelerometer without solid proof mass is numerically and experimentally studied in this paper. The accelerometer consists of a micro heater and two temperature sensors which measure the temperature difference between two symmetrical positions on both sides of the micro heater. The temperature difference is caused by free convection due to acceleration. Thermal optimization on the accelerometer is conducted based on numerical simulation. Three important indexes of the accelerometer, linearity, sensitivity and frequency response are discussed respectively. The results show that linearity relates with the non-dimensional number Gr, only when Gr is in the range from 10−2 to 103, good linearity can be achieved. The optimum sensor position for high sensitivity and good linearity is near at x/D=0.3. An increase of heating power or cavity size leads to an increase in the sensitivity. The working media that has small density ρ and large thermal diffusivity α is favorable for fast frequency response, the one having large density ρ and small kinematic viscosity υ will be advantageous for high sensitivity. Experimental tests prove that the optimized convective accelerometer has good linearity, high sensitivity and preferable frequency response.

Similar content being viewed by others

Author information

Authors and Affiliations

Additional information

Received on 9 March 2001 / Published online: 29 November 2001

Rights and permissions

About this article

Cite this article

Luo, X., Li, Z., Guo, Z. et al. Thermal optimization on micromachined convective accelerometer. Heat and Mass Transfer 38, 705–712 (2002). https://doi.org/10.1007/s002310100266

Issue Date:

DOI: https://doi.org/10.1007/s002310100266