Abstract

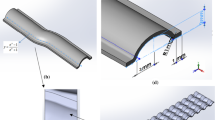

A relatively novel concept in plate heat exchangers is Pillow Plate Heat Exchanger (PPHX), which has demonstrated promising potential in heat transfer efficiency. However, the concept leads to a higher pressure drop compared to controversial models, and still, the effects of its geometrical parameters and operational conditions on efficiency are not clarified, comprehensively. In this study, a PPHX is designed and simulated to clarify the major reasons for pressure drop and entropy generation. In this regard, a 3D model of PPHX by considering conjugate heat transfer is developed and numerically investigated by using ANSYS Fluent. The calculations are accomplished for a wide range of Re numbers (\({10}^{3}\) to \(2.1\times {10}^{4}\)) consisting of both laminar and turbulent flow regimes. The results are presented in terms of frictional coefficient, Colburn factor, heat transfer coefficient, entropy generation and second law efficiency for different welding spot diameters. It is observed that while increasing the diameter causes a higher pressure drop, it lowers heat transfer and irreversibility. Up to 12% variation in the efficiency is obtained for considered diameters. Meanwhile, although entropy generation due to temperature variation plays a major role in total entropy, entropy generation due to pressure drop has shown an exponential increment as the Re number increases.

Similar content being viewed by others

Abbreviations

- \({A}_{w}\) :

-

Wetted area (m2)

- \({c}_{p}\) :

-

Specific heat (W/kg.K)

- \({d}_{h}\) :

-

Hydraulic diameter (m)

- f :

-

Frictional coefficient

- H :

-

Enthalpy (J/kg)

- h :

-

Heat transfer coefficient (W/m2.K)

- IC:

-

Inner channel

- j :

-

Colburn factor

- k :

-

Kinetic energy

- m :

-

Mass flow rate (kg/s)

- Nu :

-

Nusselt number

- 0C:

-

Outer channel

- p :

-

Pressure (Pa)

- Pr :

-

Prandtl number

- Re :

-

Reynolds number

- S :

-

Entropy (J/kg.K)

- \(\dot{S}\) ̇:

-

Entropy generation (W/K)

- T :

-

Temperature (°C)

- \({T}_{0}\) :

-

Environmental temperature (°C)

- u :

-

Velocity vector (m/s)

- V :

-

Volume (m3)

- x, y:

-

Cartesian coordinates

- \({\delta }_{D}\) :

-

Welding spot diameter (m)

- \({\delta }_{L}\) :

-

Longitudinal length (m)

- \({\delta }_{T}\) :

-

Transversal length (m)

- \({\delta }_{H}\) :

-

Inner channel height (m)

- \({\delta }_{P}\) :

-

Outer channel height (m)

- \(\mu\) :

-

Dynamic viscosity (Pa.s)

- \(\nu\) :

-

Kinematic viscosity (m2/s)

- \(\rho\) :

-

Density (m3)

- \(\epsilon\) :

-

Turbulent dissipation

- \({\mu }_{t}\) :

-

Turbulent viscosity

- \(\psi\) :

-

Exergy (J/kg)

- \(\eta\) :

-

Efficiency

- \({\tau }_{w}\) :

-

Wall shear stress

- avg :

-

Average

- e :

-

Exit

- i :

-

In

- m :

-

Mean

- P :

-

Frictional

- T :

-

Thermal

References

Ghasemi K, Tasnim S, Mahmud S (2022) PCM, nano/microencapsulation and slurries: A review of fundamentals, categories, fabrication, numerical models and applications. Sustain Energy Technol Assess 52:102084. https://doi.org/10.1016/j.seta.2022.102084

Gharehghani A, Ghasemi K, Siavashi M, Mehranfar S (2021) Applications of porous materials in combustion systems: A comprehensive and state-of-the-art review. Fuel 304:121411. https://doi.org/10.1016/j.fuel.2021.121411

Vahedi M, Mollaei Barzi Y, Firouzi M (2021) Two-phase simulation of nanofluid flow in a heat exchanger with grooved wall. J Therm Anal Calorim 146(3):1297–1321. https://doi.org/10.1007/s10973-020-10066-6

Raveendran PS, Joseph Sekhar S (2017) Exergy analysis of a domestic refrigerator with brazed plate heat exchanger as condenser. J Therm Anal Calorim 127(3):2439–2446. https://doi.org/10.1007/s10973-016-5847-2

Tiwari AK, Javed S, Oztop HF, Said Z, Pandya NS (2021) Experimental and numerical investigation on the thermal performance of triple tube heat exchanger equipped with different inserts with WO3/water nanofluid under turbulent condition. Int J Therm Sci 164:106861. https://doi.org/10.1016/j.ijthermalsci.2021.106861

Monfared M, Shahsavar A, Bahrebar MR (2019) Second law analysis of turbulent convection flow of boehmite alumina nanofluid inside a double-pipe heat exchanger considering various shapes for nanoparticle. J Therm Anal Calorim 135(2):1521–1532. https://doi.org/10.1007/s10973-018-7708-7

Khodabandeh E, Boushehri R, Akbari OA, Akbari S, Toghraie D (2021) Numerical investigation of heat and mass transfer of water–silver nanofluid in a spiral heat exchanger using a two-phase mixture method. J Therm Anal Calorim 144(3):1003–1012. https://doi.org/10.1007/s10973-020-09533-x

Afrouzy ZA, Taghavi M (2021) Thermo-economic analysis of a novel integrated structure for liquefied natural gas production using photovoltaic panels. J Therm Anal Calorim 145(3):1509–1536. https://doi.org/10.1007/s10973-021-10769-4

Vahabzadeh Bozorg M, Siavashi M (2019) Two-phase mixed convection heat transfer and entropy generation analysis of a non-Newtonian nanofluid inside a cavity with internal rotating heater and cooler. Int J Mech Sci 151:842–857. https://doi.org/10.1016/j.ijmecsci.2018.12.036

Garoosi F, Rashidi MM (2017) Two phase flow simulation of conjugate natural convection of the nanofluid in a partitioned heat exchanger containing several conducting obstacles. Int J Mech Sci 130:282–306. https://doi.org/10.1016/j.ijmecsci.2017.06.020

Salilih EM, Abu-Hamdeh NH, Oztop HF (2021) Analysis of double U-tube ground heat exchanger for renewable energy applications with two-region simulation model by combining analytical and numerical techniques. Int Commun Heat Mass Transf 123:105144. https://doi.org/10.1016/j.icheatmasstransfer.2021.105144

Hossain SMZ, Irfan MF, Elkanzi EM, Saif KM (2021) Fabrication of a hybrid shell and double pipe heat exchanger by means of design and performance assessment. Chem Eng Process Process Intensif 165:108430. https://doi.org/10.1016/j.cep.2021.108430

Tran JM, Piper M, Kenig EY, Scholl S (2018) Pillow-Plate Heat Exchangers: Fundamental Characteristics. In: Bart HJ, Scholl S (eds) Innovative Heat Exchangers. Springer, Cham, pp 233–245. https://doi.org/10.1007/978-3-319-71641-1_7

Abou Elmaaty TM, Kabeel AE, Mahgoub M (2017) Corrugated plate heat exchanger review. Renew Sustain Energy Rev 70:852–860. https://doi.org/10.1016/j.rser.2016.11.266

Arsenyeva O, Tran J, Piper M, Kenig E (2019) An approach for pillow plate heat exchangers design for single-phase applications. Appl Therm Eng 147:579–591. https://doi.org/10.1016/j.applthermaleng.2018.08.083

Shirzad M, Ajarostaghi SSM, Delavar MA, Sedighi K (2019) Improve the thermal performance of the pillow plate heat exchanger by using nanofluid: Numerical simulation. Adv Powder Technol 30(7):1356–1365. https://doi.org/10.1016/j.apt.2019.04.011

Piper M, Kenig EY (2017) Pillow plate heat exchangers. https://patents.google.com/patent/DE102016005999A1/en. Accessed 23 Feb 2021

Kumar S, Premachandran B, Subbarao PMV (2020) Large eddy simulation of single-phase forced convection in pillow plate channel with periodic boundary conditions. Int J Heat Mass Transf 149:119176. https://doi.org/10.1016/j.ijheatmasstransfer.2019.119176

Nguyen DH, Ahn HS (2021) A comprehensive review on micro/nanoscale surface modification techniques for heat transfer enhancement in heat exchanger. Int J Heat Mass Transf 178:121601. https://doi.org/10.1016/j.ijheatmasstransfer.2021.121601

Mitrovic J, Peterson R (2007) Vapor Condensation Heat Transfer in a Thermoplate Heat Exchanger. Chem Eng Technol 30(7):907–919. https://doi.org/10.1002/ceat.200700082

Mitrovic J, Maletic B (2011) Numerical Simulation of Fluid Flow and Heat Transfer in Thermoplates. Chem Eng Technol 34(9):1439–1448. https://doi.org/10.1002/ceat.201100271

Piper M, Olenberg A, Tran JM, Kenig EY (2015) Determination of the geometric design parameters of pillow-plate heat exchangers. Appl Therm Eng 91:1168–1175. https://doi.org/10.1016/j.applthermaleng.2015.08.097

Piper M, Zibart A, Tran JM, Kenig EY (2016) Numerical investigation of turbulent forced convection heat transfer in pillow plates. Int J Heat Mass Transf 94:516–527. https://doi.org/10.1016/j.ijheatmasstransfer.2015.11.014

Piper M, Zibart A, Djakow E, Springer R, Homberg W, Kenig EY (2019) Heat transfer enhancement in pillow-plate heat exchangers with dimpled surfaces: A numerical study. Appl Therm Eng 153:142–146. https://doi.org/10.1016/j.applthermaleng.2019.02.082

Goedecke R, Scholl S (2015) Enlarged operation ranges for thermosiphon reboilers using pillow plates. Chem Eng Res Des 99:58–66. https://doi.org/10.1016/j.cherd.2015.05.037

Eldeeb R, Aute V, Radermacher R (2020) Pillow plate heat exchanger weld shape optimization using approximation and parallel parameterized CFD and non-uniform rational B-splines. Int J Refrig 110:121–131. https://doi.org/10.1016/j.ijrefrig.2019.10.024

Zibart A, Kenig EY (2021) Numerical investigation of conjugate heat transfer in a pillow-plate heat exchanger. Int J Heat Mass Transf 165:120567. https://doi.org/10.1016/j.ijheatmasstransfer.2020.120567

Arsenyeva O, Piper M, Zibart A, Olenberg A, Kenig EY (2019) Investigation of heat transfer and hydraulic resistance in small-scale pillow-plate heat exchangers. Energy 181:1213–1224. https://doi.org/10.1016/j.energy.2019.05.099

Tran JM, Linnemann M, Piper M, Kenig EY (2017) On the coupled condensation-evaporation in pillow-plate condensers: Investigation of cooling medium evaporation. Appl Therm Eng 124:1471–1480. https://doi.org/10.1016/j.applthermaleng.2017.06.050

Kandlikar SG (1990) A General Correlation for Saturated Two-Phase Flow Boiling Heat Transfer Inside Horizontal and Vertical Tubes. J Heat Transf 112(1):219–228. https://doi.org/10.1115/1.2910348

Shirzad M, Delavar MA, Ajarostaghi SSM, Sedighi K (2019) Evaluation the effects of geometrical parameters on the performance of pillow plate heat exchanger. Chem Eng Res Des 150:74–83. https://doi.org/10.1016/j.cherd.2019.06.032

Yousofvand R, Derakhshan S, Ghasemi K, Siavashi M (2017) MHD transverse mixed convection and entropy generation study of electromagnetic pump including a nanofluid using 3D LBM simulation. Int J Mech Sci 133:73–90. https://doi.org/10.1016/j.ijmecsci.2017.08.034

Launder BE, Spalding DB (1974) The numerical computation of turbulent flows. Comput Methods Appl Mech Eng 3(2):269–289. https://doi.org/10.1016/0045-7825(74)90029-2

Shih T-H, Liou WW, Shabbir A, Yang Z, Zhu J (1994) A new k-epsilon eddy viscosity model for high Reynolds number turbulent flows: Model development and validation. NASA STIRecon Tech. Rep. N, vol 95. http://adsabs.harvard.edu/abs/1994STIN...9511442S. Accessed 23 Feb 2021

de Lemos MJS (2012) 11 - Applications in Hybrid Media. In: de Lemos MJS (ed) Turbulence in Porous Media, 2nd edn. Elsevier, Oxford, pp 199–352. https://doi.org/10.1016/B978-0-08-098241-0.00011-5

Kakaç S, Liu H, Pramuanjaroenkij A (2012) Heat Exchangers: Selection, Rating, and Thermal Design, 3rd edn. CRC Press, Boca Raton, FL

He Y-L, Zhang Y (2012) Chapter Two - Advances and Outlooks of Heat Transfer Enhancement by Longitudinal Vortex Generators. In: Sparrow EM, Cho YI, Abraham JP, Gorman JM (eds) Advances in Heat Transfer, vol 44. Elsevier, pp 119–185. https://doi.org/10.1016/B978-0-12-396529-5.00002-0

Demirel Y (2002) Chapter 5 - Entropy and exergy. In: Demirel Y (ed) Nonequilibrium Thermodynamics. Elsevier Science, Amsterdam, pp 102–123. https://doi.org/10.1016/B978-044450886-7/50005-9

Bıyıkoğlu A (2012) Thermodynamic Analysis:optimization Of A Thermal Energy Storage System: The Second Law Efficiency. LAP LAMBERT Academic Publishing

Mangrulkar CK, Abraham JD, Dhoble AS (2019) Numerical studies on the near wall y+ effect on heat and flow characteristics of the cross flow tube bank. J Phys Conf Ser 1240:012110. https://doi.org/10.1088/1742-6596/1240/1/012110

Funding

The authors would appreciate the financial support provided by the Ontario Ministry of Agriculture, Food and Rural Affairs (OMAFRA) under the UG-HQP-2020–100600 Award.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interests

On behalf of all authors, the corresponding author states that there is no confict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ghasemi, K., Tasnim, S. & Mahmud, S. Second law analysis of pillow plate heat exchanger to enhance thermal performance and its simulation studies. Heat Mass Transfer 59, 55–66 (2023). https://doi.org/10.1007/s00231-022-03245-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-022-03245-8