Abstract

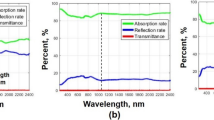

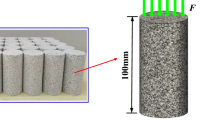

This paper reports the experimental investigation of the modified specific energy, mechanical properties and temperature field of limestone rock that was irradiated by continuous wave fiber laser at different irradiation powers. Results show that the specific energy decreases nonlinearly from 17 kJ/cm3 to 11 kJ/cm3 and rate of perforation increases from 0.2 mm/s to 0.65 mm/s with laser power increasing from 600 W to 1000 W. The modified specific energy which is used to evaluate rock excavation efficiency is observed to decrease monotonously from 0.27 kJ/cm3 to 0.068 kJ/cm3 with increasing laser power. Higher laser power results in larger surface temperature and temperature gradient. The rate of rock surface temperature irradiated by laser with power of 1000 W reaches 14 °C/ms within 140 ms. The temperature gradient, with largest value of 1400 °C/mm near to the sample axis, decreases sharply with radius. The high solution 3D X-ray microanalyser (XRM) images show that the rock perforation is a V-shaped hole and obvious cracks penetrate the whole rock sample. The extremely rough surface and well-developed cracks for irradiated samples are observed through scanning electron microscope (SEM). X-ray diffraction (XRD) results also show that the main minerals of rock after irradiation are quite different from that of original sample. The maximum reduction rate of compressive strength of irradiated rock with laser power of 1000 W is 60%, and the maximum increasing rate of peak strain of irradiated rock with laser power of 800 W is 65%.

Similar content being viewed by others

References

Zhao Y, Li PF (2018) A statistical analysis of China’s traffic tunnel development data. Eng 4:3–5

Zhang WQ, Sun Q, Zhu S (2017) Experimental study on mechanical and porous characteristics of limestone affected by high temperature. Appl Therm Eng 110:356–362

Mou HW, Xin PH, Luo W (2016) Development status and future development of laser breaking technology. Petroche Ind Appl 35:1–5

Jurewicz BR (1976) Rock excavation with laser assistance. Int J Rock Mech Min Sci Geomech Abs 13:207–219

Yan F, Gu YF, Wang YJ, Wang CM, Hu XY, Peng HX, Yao ZL, Wang Z, Shen Y (2013) Study on the interaction mechanism between laser and rock during perforation. Opt Laser Technol 54:303–308

Gahan BC, Parker RA, Batarseh S, Figueroa H, Reed CB, Xu ZY (2001) Laser drilling: determination of energy required to remove rock. Soc Petrol Eng SPE71466:1–11

Xu ZK, Reed CB, Kornecki G, Gahan BC (2003) Specific energy for pulsed laser rock drilling. J Laser Appl 15:25–30

Xu ZK, Reed CB, Parker RA, Gahan BC, Graves RM, Figueroa H (2002) Laser rock drilling by a super-pulsed CO2 laser beam. Office of Scientific and Technical Information Technical Reports

Ahmadi M, Erfan MR, Torkamany MJ, Ssfian GA (2011) The effect of interaction time and saturation of rock on specific energy in ND:YAG laser perforating. Opt Laser Technol 43:226–231

Erfan MR, Shahriar K, Sharifzadeh M, Ahmadi M, Torkamany MJ (2017) Moving perforation of rocks using long pulse Nd: YAG laser. Opt Laser Eng 94:12–16

Rad AG, Bazargan M, Jalalifar H, Koohian A (2014) Laboratory experiment: investigation of CO2 laser irradiation effects on limestone of Iran sarvak formation. J Mod Phys 9

Bharatish A, Kumar BK, Rajath R, Murthy HN (2018) Investigation of effect of CO2 laser parameters on drilling characteristics of rocks encountered during mining. J King Saud Univ:1–7

Li MY, Han B, Zhang SY, Song LX, He QK (2018) Numerical simulation and experimental investigation on fracture mechanism of granite by laser irradiation. Opt Laser Technol 106:52–60

Ndeda RA, Sebusang SEM, Marumo R, Ogur EO (2017) On the role of laser pulses on spallation of granite. Lasers Manuf Mater Process 4:60–75

Hu MX, Yang B, Chen HW, Lu BL, Bai JT (2018) Engineering characteristics of laser perforation with a high power fiber laser in oil and gas wells. Infrared Phys Tech 92:103–108

Yi XZ, Gao DL, Ming Y, Yu WJ (2005) Physical model of removing rock by laser and its heat transfer characteristics. Nat Gas Ind 25:62–65

Yi XZ, Qi HY, Yu WJ, Gao DL (2005) Research on heat transfer characteristics of the removal rock by laser. Opt Optoelectronic Technol 3:11–13

Bazargan M, Koohian A, Jalalyfar H, Fatideh MH (2014) Interactions between high power fiber laser and rock in shale formation during drilling and production operation. 6th Saint Petersburg international conference and exhibition

Li MY, Han B, Zhang Q, Zhang SY, He QK (2019) Investigation on rock breaking for sandstone with high power density laser beam. Optik 180:635–647

Kariminezhad H, Amani H, Moosapoor M (2016) A laboratory study about laser perforation of concrete for application in oil and gas wells. J Nat Gas Sci Eng 32:566–573

Acknowledgements

The authors thank the National Natural Science Foundation of China (51204170, 51323004) and 111 Program (B14021) for funding this project. The authors also thank Dr. Veerle Vandeginste and Professor Jo Darkwa at University of Nottingham for their guidance and advice to this manuscript.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, Y., Shi, Y., Jiang, J. et al. Experimental study on modified specific energy, temperature field and mechanical properties of Xuzhou limestone irradiated by fiber laser. Heat Mass Transfer 56, 161–173 (2020). https://doi.org/10.1007/s00231-019-02682-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-019-02682-2