Abstract

Polymeric foams are one of the most important insulating materials due to their low thermal conductivity. The comprehensive investigation of the thermal behavior of these materials is experimentally difficult, costly, and time-consuming. In this study, a step-wise approach is used in order to predict thermal conductivity of the polymeric foams. The results demonstrate that two different models estimate the thermal conductivity of the polystyrene foams with cell sizes smaller than 100 μm and larger than 100 μm with an error almost smaller than 10%. According to these theoretical models, a comprehensive investigation is performed on the thermal-insulation performance of polystyrene foams. The results indicate that the thermal conductivity reduces by decreasing the cell size but there is an optimum foam density for achieving the smallest thermal conductivity. The effects of foam density and cell size are studied on the different mechanisms of thermal conductivity. In the following, a new approach is offered based on the cell size and the foam density using response surface method (RSM). The reliability of the proposed regression model is checked not only using analysis of variance (ANOVA) tool of RSM but also in comparison to empirical results.

Similar content being viewed by others

Abbreviations

- ϵ VF :

-

Void fraction

- K n :

-

Knudsen number

- λ gas :

-

Bulk gas conductivity, 0.026 W/mK

- λ solid :

-

Bulk solid conductivity, W/mK

- l mean :

-

Mean free path, 70 nm for air

- φ c :

-

Cell size, μm

- φ :

-

Expansion ratio

- N:

-

Cell density, cell.cm−3

- f s :

-

Strut fraction

- V struts :

-

Volumetric fraction of struts

- V walls :

-

Volumetric fraction of cell walls

- φ s :

-

Strut diameter, μm

- d w :

-

Cell wall thickness, μm

- n:

-

Effective index of refraction

- T:

-

Temperature, K

- K R :

-

Rosseland mean extinction coefficient, m−1

- K struts :

-

Extinction coefficient of struts, m−1

- K walls :

-

Extinction coefficient of cell walls

- K Solid :

-

Extinction coefficient of solid polymer, m−1

- β :

-

Efficiency of the energy transfer between gas molecules and cell walls

- λ:

-

Thermal conductivity

- ρ :

-

Density

- σ :

-

Stefan-Boltzmann constant

- t:

-

Total

- s:

-

Solid

- g:

-

Gas

- r:

-

Radiation

- f:

-

Foam

References

Cuce E, Cuce PM, Wood CJ, Riffat SB (2014) Toward aerogel based thermal superinsulation in buildings: a comprehensive review. Renew Sust Energ Rev 34:273–299

Canadian Energy Overview 2014 (2014) National Energy Board

König J, Petersen RR, Yue Y (2015) Fabrication of highly insulating foam glass made from CRT panel glass. Ceram Int 41(8):9793–9800

Petersen RR, König J, Yue Y (2015) The mechanism of foaming and thermal conductivity of glasses foamed with MnO2. J Non-Cryst Solids 425:74–82

Zhao B, Zhao C, Wang C, Park CB (2018) Poly (vinylidene fluoride) foams: a promising low-k dielectric and heat-insulating material. J Mater Chem C 6(12):3065–3073

Wang G, Wang C, Zhao J, Wang G, Park CB, Zhao G (2017) Modelling of thermal transport through a nanocellular polymer foam: toward the generation of a new superinsulating material. Nanoscale 9(18):5996–6009

Alvarez-Lainez M, Rodriguez-Perez MA, De Saja JA (2008) Thermal conductivity of open-cell polyolefin foams. J Polym Sci B Polym Phys 46:212–221

Placido E, Arduini-Schuster MC, Kuhn J (2005) Thermal properties predictive model for insulating foams. Infrared Phys Technol 46:219–231

Campo-Arnáiz RA, Rodríguez-Pérez MA, Calvo B, De Saja JA (2005) Extinction coefficient of polyolefin foams. J Polym Sci B Polym Phys 43:1608–1617

Glicksman L, Schuetz M, Sinofsky M (1987) Radiation heat transfer in foam insulation. Int J Heat Mass Transf 30:187–197

Kaemmerlen A, Vo C, Asllanaj F, Jeandel G, Baillis D (2010) Radiative properties of extruded polystyrene foams: predictive model and experimental results. J Quant Spectrosc Radiat Transf 111:865–877

Notario B, Pinto J, Solorzano E, De Saja JA, Dumon M, Rodríguez-Pérez MA (2015) Experimental validation of the Knudsen effect in nanocellular polymeric foams. Polymer 56:57–67

Gong P, Buahom P, Tran MP, Saniei M, Park CB, Pötschke P (2015) Heat transfer in microcellular polystyrene/multi-walled carbon nanotube nanocomposite foams. Carbon 93:819–829

Wang G, Zhao J, Wang G, Mark LH, Park CB, Zhao G (2017) Low-density and structure-tunable microcellular PMMA foams with improved thermal-insulation and compressive mechanical properties. Eur Polym J 95:382–393

Wang G, Zhao G, Dong G, Mu Y, Park CB, Wang G (2018) Lightweight, super-elastic, and thermal-sound insulation bio-based PEBA foams fabricated by high-pressure foam injection molding with mold-opening. Eur Polym J 103:68–79

Zhao J, Zhao Q, Wang L, Wang C, Guo B, Park CB, Wang G (2018) Development of high thermal insulation and compressive strength BPP foams using mold-opening foam injection molding with in-situ fibrillated PTFE fibers. Eur Polym J 98:1–10

Shirvan KM, Mamourian M, Mirzakhanlari S, Ellahi R (2016) Two phase simulation and sensitivity analysis of effective parameters on combined heat transfer and pressure drop in a solar heat exchanger filled with nanofluid by RSM. J Mol Liq 220:888–901

Shirvan KM, Mamourian M, Mirzakhanlari S, Ellahi R (2017) Numerical investigation of heat exchanger effectiveness in a double pipe heat exchanger filled with nanofluid: a sensitivity analysis by response surface methodology. Powder Technol 313:99–111

Nejad SJH, Hasanzadeh R, Doniavi A, Modanloo V (2017) Finite element simulation analysis of laminated sheets in deep drawing process using response surface method. Int J Adv Manuf Technol 93(9–12):3245–3259

Schellenberg J, Wallis M (2010) Dependence of thermal properties of expandable polystyrene particle foam on cell size and density. J Cell Plast 46:209–222

Xu X, Park CB, Xu D, Pop-Iliev R (2003) Effects of die geometry on cell nucleation of PS foams blown with CO2. Polym Eng Sci 43:1378–1390

Lee ST, Park CB, Ramesh NS (2006) Polymeric foams: science and technology. CRC Press, Boca Raton

Xu J, Wu T, Zhang J, Chen H, Sun W, Peng C (2017) Microstructure measurement and microgeometric packing characterization of rigid polyurethane foam defects. Cell Polym 36:183

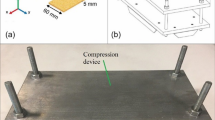

Hasanzadeh R, Azdast T, Doniavi A, Lee RE (2019) Multi-objective optimization of heat transfer mechanisms of microcellular polymeric foams from thermal-insulation point of view. Therm Sci Eng Prog 9:21–29

Forest C, Chaumont P, Cassagnau P, Swoboda B, Sonntag P (2015) Polymer nano-foams for insulating applications prepared from CO2 foaming. Prog Polym Sci 41:122–145

Gong P, Wang G, Tran MP, Buahom P, Zhai S, Li G, Park CB (2017) Advanced bimodal polystyrene/multi-walled carbon nanotube nanocomposite foams for thermal insulation. Carbon 120:1–10

Li T, Zhao G, Wang G, Zhang L, Hou J (2019) Thermal-insulation, electrical, and mechanical properties of highly-expanded PMMA/MWCNT nanocomposite foams fabricated by supercritical CO2 foaming. Macromol Mater Eng. https://doi.org/10.1002/mame.201800789

Arduini-Schuster M, Manara J, Vo C (2015) Experimental characterization and theoretical modeling of the infrared-optical properties and the thermal conductivity of foams. Int J Therm Sci 98:156–164

Gedler G, Antunes M, Borca-Tasciuc T, Velasco JI, Ozisik R (2016) Effects of graphene concentration, relative density and cellular morphology on the thermal conductivity of polycarbonate–graphene nanocomposite foams. Eur Polym J 75:190–199

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hasanzadeh, R., Azdast, T., Doniavi, A. et al. A prediction model using response surface methodology based on cell size and foam density to predict thermal conductivity of polystyrene foams. Heat Mass Transfer 55, 2845–2855 (2019). https://doi.org/10.1007/s00231-019-02628-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-019-02628-8