Abstract

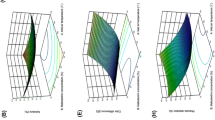

To study the kinetics of color degradation, the tomato paste was designed to be processed at three different temperatures including 60, 70 and 80 °C for 25, 50, 75 and 100 min. a/b ratio, total color difference, saturation index and hue angle were calculated with the use of three main color parameters including L (lightness), a (redness-greenness) and b (yellowness-blueness) values. Kinetics of color degradation was developed by Arrhenius equation and the alterations were modelled with the use of response surface methodology (RSM). It was detected that all of the studied responses followed a first order reaction kinetics with an exception in TCD parameter (zeroth order). TCD and a/b respectively with the highest and lowest activation energy presented the highest sensitivity to the temperature alterations. The maximum and minimum rates of alterations were observed by TCD and b parameters, respectively. It was obviously determined that all of the studied parameters (responses) were affected by the selected independent parameters.

Similar content being viewed by others

References

Ahmed J, Shivhare US, Kaur M (2002a) Thermal colour degradation kinetics of mango puree. Int J Food Prop 5(2):359–366

Hackett MM, Lee JH, Francis D, Schwartz SJ (2004) Thermal stability and isomerization of lycopene in tomato oleoresins from different varieties. J Food Sci 69(7):536–541

Rodrigo D, van Loey A, Hendrickx M (2007) Combined thermal and high pressure colour degradation of tomato puree and strawberry juice. J Food Eng 79(2):553–560

Jabbari S-S, Jafari SM, Dehnad D, Shahidi S-A (2018). Changes in lycopene content and quality of tomato juice during thermal processing by a nanofluid heating medium. J Food Eng 230:1–7

Farzaneh V, Carvalho IS (2015) A review of the health benefit potentials of herbal plant infusions and their mechanism of actions. Ind Crop Prod 65(2015). https://doi.org/10.1016/j.indcrop.2014.10.057

Baik OD, Mittal GS (2003) Kinetics of tofu color changes during deep-fat frying. LWT Food Sci Technol 36(1):43–48

Pedreschi F, Moyano P, Kaack K, Granby K (2005) Color changes and acrylamide formation in fried potato slices. Food Res Int 38(1):1–9

Lau MH, Tang J, Swanson BG (2000) Kinetics of textural and color changes in green asparagus during thermal treatments. J Food Eng 45(4):231–236

Chutintrasri B, Noomhorm A (2007) Color degradation kinetics of pineapple puree during thermal processing. LWT Food Sci Technol 40(2):300–306

Ahmed J, Ramaswamy HS (2005) Effect of temperature on dynamic rheology and colour degradation kinetics of date paste. Food Bioprod Process 83(3):198–202

Suh HJ, Noh DO, Kang CS, Kim JM, Lee SW (2003) Thermal kinetics of color degradation of mulberry fruit extract. Food Nahrung 47(2):132–135

Ganje M, Jafari SM, Dusti A, Dehnad D, Amanjani M, Ghanbari V (2016) Modeling quality changes in tomato paste containing microencapsulated olive leaf extract by accelerated shelf life testing. Food Bioprod Process 97:12–19

Jafari SM, Ganje M, Dehnad D, Ghanbari V, Hajitabar J (2017). Arrhenius equation modeling for the shelf life prediction of tomato paste containing a natural preservative. J Sci Food Agr 97(15):5216–5222

Jafari SM, Ghanbari V, Dehnad D, Ganje M (2018). Neural networks modeling of Aspergillus flavus growth in tomato paste containing microencapsulated olive leaf extract. J Food Safety 38(1):e12396

Yolmeh M, Jafari SM (2017). Applications of Response Surface Methodology in the Food Industry Processes. Food Bioprocess Tech 10(3):413–433

Sarfarazi M, Jafari SM, Rajabzadeh G (2015). Extraction Optimization of Saffron Nutraceuticals Through Response Surface Methodology. Food Anal Methods 8(9), 2273–2285

Khazaei KM, Jafari SM, Ghorbani M, Kakhki AH, Sarfarazi M (2016). Optimization of Anthocyanin Extraction from Saffron Petals with Response Surface Methodology. Food Anal Methods 9(7):1993–2001

Shahraki MH, Jafari SM, Mashkour M, Esmaeilzadeh E (2013). Optimization of closedcycle fluidized bed drying of sesame seeds using response surface methodology and genetic algorithms. Int J Food Eng 10(1):167–181

Salimi A, Maghsoudlou Y, Jafari SM, Mahoonak, AS, Kashaninejad M, Ziaiifar AM (2015). Preparation of Lycopene Emulsions by Whey Protein Concentrate and Maltodextrin and Optimization by Response Surface Methodology. J Dispersion Sci Tech 36(2), 274–283

Jalili F, Jafari SM, Emam-Djomeh Z, Malekjani N, Farzaneh V (2017) Optimization of ultrasound-assisted extraction of oil from canola seeds with the use of response surface methodology. Food Anal Methods 11(2):598–612

Assadpour E, Maghsoudlou Y, Jafari S-M, Ghorbani M., Aalami M (2016). Optimization of folic acid nano-emulsification and encapsulation by maltodextrin-whey protein double emulsions. Int J Biological Macromolecules 86:197–207

Tiwari BK, Muthukumarappan K, O’ Donnell CP, Cullen PJ (2008). Modelling colour degradation of orange juice by ozone treatment using response surface methodology. J Food Eng 88(4), 553–560

Maskan M (2001) Kinetics of colour change of kiwifruits during hot air and microwave drying. J Food Eng 48(2):169–175

Ahmed J, Shivhare US, Raghavan GSV (2000) Rheological characteristics and kinetics of colour degradation of green chilli puree. J Food Eng 44(4):239–244

Lozano JE, Ibarz A (1997) Colour changes in concentrated fruit pulp during heating at high temperatures. J Food Eng 31(3):365–373

Garza S, Ibarz A, Pagán J, Giner J (1999) Non-enzymatic browning in peach puree during heating. Food Res Int 32(5):335–343

Ibarz A, Pagán J, Garza S (1999) Kinetic models for colour changes in pear puree during heating at relatively high temperatures. J Food Eng 39(4):415–422

Sánchez AH, Rejano L, Montaño A (1991) Kinetics of the destruction by heat of colour and texture of pickled green olives. J Sci Food Agric 54(3):379–385

Schwartz SJ, Lorenzo TV (1991) Chlorophyll stability during continuous aseptic processing and storage. J Food Sci 56(4):1059–1062

Rhim JW, Nunes RV, Jones VA, Swartzel KR (1989) Kinetics of color change of grape juice generated using linearly increasing temperature. J Food Sci 54(3):776–777

Lovrić T, Sablek Z, Bošković M (1970) Cis-trans isomerisation of lycopene and colour stability of foam—mat dried tomato powder during storage. J Sci Food Agric 21(12):641–647

Rattanathanalerk M, Chiewchan N, Srichumpoung W (2005) Effect of thermal processing on the quality loss of pineapple juice. J Food Eng 66(2):259–265

Ahmed J, Shivhare US, Sandhu KS (2002b) Thermal degradation kinetics of carotenoids and visual color of papaya puree. J Food Sci 67(7):2692–2695

Hayakawa K-I, Timbers GE (1977) Influence of heat treatment on the quality of vegetables: changes in visual green color. J Food Sci 42(3):778–781

Ávila IMLB, Silva CLM (1999) Modelling kinetics of thermal degradation of colour in peach puree. J Food Eng 39(2):161–166

Maskan M (2003) Change in colour and rheological behaviour of sunflower seed oil during frying and after adsorbent treatment of used oil. Eur Food Res Technol 218(1):20–25

Boakye K, Mittal GS (1996) Changes in colour of beef m. Longissimus dorsi muscle during ageing. Meat Sci 42(3):347–354

Reyes LF, Cisneros-Zevallos L (2007) Degradation kinetics and colour of anthocyanins in aqueous extracts of purple- and red-flesh potatoes (Solanum tuberosum L.). Food Chem 100(3):885–894

Choi K, Lee G, Han YJ, Bunn JM (1995) Tomato maturity evaluation using color image analysis. Transactions of the ASAE 38(1):171–176

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There is no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ganje, M., Jafari, S.M., Farzaneh, V. et al. Kinetics modelling of color deterioration during thermal processing of tomato paste with the use of response surface methodology. Heat Mass Transfer 54, 3663–3671 (2018). https://doi.org/10.1007/s00231-018-2394-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-018-2394-3