Abstract

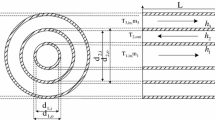

This paper presents a numerical analysis by using the finite difference method to describe the steady and unsteady state thermal behavior of triple concentric-tube heat exchanger with parallel flow and counter flow arrangements. One gives the temperature variations of the three fluids and three walls with time along the triple concentric-tube heat exchanger. The fluids have a time lag and the response of triple concentric-tube heat exchanger in parallel flow configuration is faster than those of a counterflow arrangement, its performances are always lower than those of a counterflow triple concentric-tube heat exchanger. The heat transfer coefficients by convection of the three fluids vary with time in addition to the temperature and the heat exchanger performances are lower in unsteady state than the steady state case.

Similar content being viewed by others

Abbreviations

- TTHE:

-

Triple concentric tube heat exchanger

- DTHE:

-

Double concentric tube heat exchanger

- A :

-

Matrix

- B :

-

Matrix

- Cp :

-

Specific heat at constant pressure (J/kg K)

- D :

-

Diameter (m)

- \(D_{h}\) :

-

Hydraulic diameter (m)

- G :

-

Mass velocity (kg/m2s)

- H :

-

Specific enthalpy (J/kg)

- h :

-

Heat transfer coefficient (W/m2K)

- L :

-

Length (m)

- m :

-

Mass (kg)

- \(\dot{m}\) :

-

Flowrate (kg/s)

- n :

-

Number of nodes

- Nu :

-

Nusselt number

- Pr :

-

Prandtl number

- R′, R :

-

Radii (m)

- Re :

-

Reynolds number

- S :

-

Heat exchange surface (m2)

- S c :

-

Cross section area (m2)

- Sp :

-

Pass area (m2)

- t :

-

Time (s)

- T :

-

Temperature (°C)

- V :

-

Volume (m3)

- x :

-

Coordinate

- y :

-

Coordinate

- α :

-

Dimensionless group

- β :

-

Dimensionless group

- γ :

-

Dimensionless group

- \(\rho\) :

-

Density (kg/m3)

- λ :

-

Thermal conductivity (W/m K)

- μ :

-

Dynamic viscosity (Pa s)

- \(\Delta t\) :

-

Temporal discretization step (s)

- \(\Delta x\) :

-

Axial discretization step (m)

- Φ :

-

Heat flux (W)

- 1:

-

Cold fluid 1

- 2:

-

Cold wall 2

- 3:

-

Hot fluid 3

- 4:

-

Hot wall 4

- 5:

-

Cold fluid 5

- 6:

-

Cold wall 6

- e :

-

External

- exp :

-

Experimental

- H :

-

Horizontal

- i :

-

Inlet, inside

- num :

-

Numerical

- o:

-

Exit

- V :

-

Vertical

- w :

-

Wall

References

Morley TB (1933) Exchange of heat between three fluids. Engineer 155:134

Rabinovich GD (1961) Steady state heat transfer among three streams in a parallel flow recuperator. Inzh.-Fiz. Zh4 11:37–43 (in Russian)

Wolf J (1964) General solution of the equations of parallel flow multichannel heat exchangers. Int J Heat Mass Transf 7(8):901–919

Aldous DD (1966) An analytical method for the design of a three-channel heat exchanger for cryogenic applications. M.S. thesis, Louisiana Polytechnic Institute, Ruston, Louisiana

Zuritz CA (1990) On the design of triple concentric-tube heat exchangers. J Food Process Eng 12(2):113–130

Ünal A (1998) Theoretical analysis of triple concentric-tube heat exchangers Part 1: mathematical modelling. Int Commun Heat Mass Transf 25(7):949–958

Ünal A (2001) Theoretical analysis of triple concentric-tube heat exchangers Part 2: case studies. Int Commun Heat Mass Transf 28(2):243–256

Sahoo PK, Ansari MIA, Datta AK (2003) A computer based iterative solution for accurate estimation of heat transfer coefficients in helical tube heat exchanger. J Food Eng 58:211–214

Batmaz E, Sandeep KP (2005) Calculation of overall heat transfer coefficients in a triple tube heat exchangers. Heat Mass Transf 41:271–279

Batmaz E, Sandeep KP (2008) Calculation of overall heat transfer coefficients and axial temperature distribution in a triple tube heat exchangers. J Food Process Eng 31:260–279

Radulescu S, Negoita IL, Onutu I (2012) Heat transfer coefficient solver for a triple concentric-tube heat exchanger in transition regime. Rev Chim (Buchar) 8:820–824

Quadir GA, Jarallah SS, Salman NJ, Badruddin IA (2013) Experimental investigation of the performance of a triple concentric pipe heat exchanger. Int J Heat Mass Transf 62:562–566

Quadir GA, Badruddin IA, Salman NJ (2014) Numerical investigation of the performance of a triple concentric pipe heat exchanger. Int J Heat Mass Transf 75:165–172

Pătrăşcioiu C, Rădulescu S (2015) Prediction of the outlet temperatures in triple concentric-tube heat exchangers in laminar flow regime: case study. Heat Mass Transf 51:59–66

Behera VM, Das DH, Nayak A (2014) Numerical analysis of triple tube heat exchanger using ANSYS. Int J Sci Eng Res 5(11):1226–1231

Kakc S, Yener Y (1987) Transient forced convection in ducts, Handbook of single phase convective heat transfer. Wiley, New York

Valladares OG (2004) Numerical simulation of triple concentric pipe heat exchangers. Int J Therm Sci 43:979–991

Nema PK, Datta AK (2005) A computer based solution to check the drop in milk outlet temperature due to fouling in a tubular heat exchanger. J Food Eng 71:133–142

Bielski S, Malinowski L (2005) An analytical method for determining transient temperature field in a parallel-flow three-fluid heat exchanger. Heat Mass Transf 32:1034–1044

Nema PK, Datta AK (2006) Improved milk fouling simulation in a helical triple tube heat exchanger. Int J Heat Mass Transf 49:3360–3370

Spalding DB (1972) A novel finite-difference formulation for differential expressions involving both first and second derivatives. Int J Numer Methods Eng 4:551–559

Nougier JP (1991) Méthodes de calcul numérique, 3rd edn. Masson, Paris

Sieder EN, Tate GE (1936) Heat transfer and pressure drop of liquids in tubes. Ind Eng Chem 28(12):1429–1435

El-Wakil N, Lachi M, Guellal M, Padet J (1995) Transient behaviour of shell and tube heat exchangers. Eurotherm Seminar 46, Pisa, Italy, pp 141–147

Guellal M, Abdesselam H (2009) Empirical correlation for the time lag of double pipe heat operating with variable flow rates. Energy Convers Manag 50:970–976

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Boultif, N., Bougriou, C. Steady and unsteady state thermal behaviour of triple concentric-tube heat exchanger. Heat Mass Transfer 53, 849–863 (2017). https://doi.org/10.1007/s00231-016-1859-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-016-1859-5