Abstract

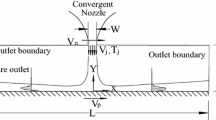

An experimental investigation was conducted to study the convective heat transfer rate from a wedge-shaped surface to a rectangular subsonic air jet impinging onto the apex of the wedge. The jet Reynolds number, nozzle-to-surface distance and the wedge angle were considered as the main parameters. Jet Reynolds number was ranged from 5,000 to 20,000 and two dimensionless nozzle-to-surface distances h/w = 4 and 10 were examined. The apex angle of the wedge ranged from 30° to 180° where the latter case corresponds with that of a flat surface. Velocity profile and turbulence intensity were provided for free jet flow using hot wire anemometer. Local and average Nusselt numbers on the impinged surface are presented for all the configurations. Based on the results presented, the local Nusselt number at the stagnation region increases as the wedge angle is decreased but, it then decreases over the remaining area of the impinged surface. Average Nusselt number over the whole surface is maximum when the wedge angle is 180° (i.e. plane surface) for any jet and nozzle-to-surface configuration.

Similar content being viewed by others

Abbreviations

- A :

-

Surface area of the foil (M2)

- h :

-

Distance from the nozzle exit to the apex of the wedge (m)

- h conv :

-

Convective heat transfer coefficient (W/m2 K)

- h o :

-

Natural convection coefficient (W/m2 K)

- I :

-

Electric current (A)

- k :

-

Thermal conductivity (W/m K)

- L :

-

Width of the foil (m)

- Nu :

-

Nusselt number (h conv w/k)

- q conv :

-

Heat transfer rate from the foil to the air jet (W/m2)

- q cond :

-

Heat transfer rate by conduction (W/m2)

- q gen :

-

Heat rate generation within the foil (W/m2)

- q rad :

-

Heat transfer rate from the foil by radiation (W/m2)

- Re:

-

Jet reynolds number (uw/ν)

- T s :

-

Surface temperature (K)

- T ∞ :

-

Ambient air temperature (K)

- t :

-

Thickness of the foil (m)

- u :

-

Nozzle exit velocity (m/s)

- V :

-

Electric voltage (V)

- w :

-

Width of the rectangular nozzle (m)

- y :

-

Streamwise direction on the foil

- Y :

-

Non-dimensional streamwise distance (y/w)

- ε:

-

Emissivity of the foil

- θ:

-

Apex angle of the wedge

- σ:

-

Boltzmann constant

- al :

-

Aluminum

- w :

-

Wood

- i :

-

Foil surface element

References

Gardon R, Akfirat C (1965) The role of turbulence in determining the heat-transfer characteristics of impinging jets. Int J Heat Mass Transf 8:1261–1272

Gardon R, Akfirat C (1966) Heat transfer characteristics of impinging two dimensional air jets. J Heat Transf 88:101–108

Martin H (1977) Heat and mass transfer between impinging gas jets and solid surfaces. Adv Heat Transf 13:1–60

McMurray DC, Myers PS, Uyehara OA (1966) Influence of impinging jet variables on local heat transfer coefficients along a flat surface with constant heat flux. Proc Third Int Heat Transf Conf vol 2:292–299

Kendoush AA (1998) Theory of stagnation region heat and mass transfer to fluid jets impinging normally on solid surface. Chem Eng Process 37:223–228

Zhou DW, Lee SJ (2007) Forced convective heat transfer with impinging rectangular jets. Int J Heat Mass Transf 50:1916–1926

Gulati P, Katti V, Prabhu SV (2009) Influence of the shape of the nozzle on local heat transfer distribution between smooth flat surface and impinging air jet. Int J Therm Sci 48:602–617

Xu P, Yu B, Qiu S, Poh HJ, Mujumdar AS (2010) Turbulent impinging jet heat transfer enhancement due to intermittent pulsation. Int J Therm Sci 49:1247–1252

Akansu YE, Sarioglu M, Kuvvet K, Yavuz T (2008) Flow field and heat transfer characteristics in an oblique slot jet impinging on a flat plate. Int Commun Heat Mass Transf 35:873–880

Song HB, Yoon SH, Lee DH (2000) Flow and heat transfer characteristics of a two-dimensional oblique wall attaching offset jet. Int J Heat Mass Transf 43:2395–2404

Eren H, Celik N (2006) Cooling of a heated flat plate by an obliquely impinging slot jet. Int. Com. Heat Mass Transf 33:372–380

Gau C, Chung CM (1991) Surface curvature effect on slot-air jet impingement cooling flow and heat transfer process. J Heat Transf 113:858–864

Faruque O, Brahma RK, Arora RC (1991) Impingement heat transfer from wedge surface. Wärme-und Stoffübertrag 26:175–179

Oosthuizen PH, Naylor D (1999) Introduction to Convective Heat Transfer Analysis. WCB/McGraw-Hill, New York

Kline SJ, McClintock FA (1953) Describing uncertainties in single sample experiments. Mech Eng 75:3–8

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rahimi, M., Irani, M. Experimental study of slot jet impingement heat transfer on a wedge-shaped surface. Heat Mass Transfer 48, 2095–2101 (2012). https://doi.org/10.1007/s00231-012-1054-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-012-1054-2