Abstract

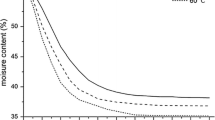

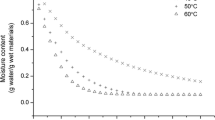

Drying characteristics of cotton stalk were investigated at four temperatures (60, 80, 100 and 120 °C) using a simultaneous thermal analyzer (TG-DSC). Heat requirements of cotton stalk during drying were calculated ranging from 189 to 406 kJ/kg. Consequently, Midilli-Kucuk model showed the best fit to experimental drying data. The values of effective diffusivity ranged from 4.38 × 10−9 to 8.15 × 10−9 m2/s, and the activation energy was calculated to be 11.6 kJ/mol.

Similar content being viewed by others

Abbreviations

- a, b, k, n :

-

Drying parameters

- k 0 :

-

Drying constants (1/min)

- D eff :

-

Effective moisture diffusivity (m2/s)

- MR exp,i :

-

Experimental moisture ratio

- MR pre,i :

-

Predicted moisture ratio

- M e :

-

Equilibrium moisture content (kg water/kg wet matter)

- M 0 :

-

Initial moisture content (kg water/kg wet matter)

- M :

-

Moisture content at any time of drying (kg water/kg wet matter)

- N :

-

Number of observations

- z :

-

Constant, positive integer

- n :

-

Number of drying constants

- R :

-

The ideal gas constant (J/mol K)

- R 2 :

-

Determination of coefficient

- χ 2 :

-

Reduced Chi-square

- t :

-

Drying time (s)

- T :

-

Drying temperature (°C)

- L :

-

Half thickness of the sample pan (m)

- D 0 :

-

The pre-exponential factor (m2/s)

- E a :

-

The activation energy for drying (kJ/mol)

References

Vispute TP, Zhang H, Sanna A, Xiao R, Huber GW (2010) Renewable chemical commodity feedstocks from integrated catalytic processing of pyrolysis oils. Science 330(6008):1222–1227

Chen LJ, Li X, Han LJ (2009) Renewable energy from agro-residues in China: solid biofuels and biomass briquetting technology. Renew Sustain Energy Rev 13(9):2689–2695

Cai JM, Chen SY (2008) Determination of drying kinetics for biomass by thermogravimetric analysis under nonisothermal condition. Dry Technol 26(12):1464–1468

Zhu Z, Kaliske M (2010) Numerical simulation of coupled heat and mass transfer in wood dried at high temperature. Heat Mass Transf 47(3):351–358

Srikiatden J, Roberts J (2006) Measuring moisture diffusivity of potato and carrot (core and cortex) during convective hot air and isothermal drying. J Food Eng 74(1):143–152

Doymaz İ (2010) Thin-layer drying characteristics of sweet potato slices and mathematical modelling. Heat Mass Transfer 47(3):277–285

Midilli A, Kucuk H (2003) Mathematical modeling of thin layer drying of pistachio by using solar energy. Energy Convers Manage 44(7):1111–1122

Li Z, Kobayashi N (2005) Determination of moisture diffusivity by thermo-gravimetric analysis under non-isothermal condition. Dry Technol 23(6):1331–1342

Doymaz İ, Tugrul N, Pala M (2006) Drying characteristics of dill and parsley leaves. J Food Eng 77(3):559–565

Doymaz İ (2007) Air-drying characteristics of tomatoes. J Food Eng 78(4):1291–1297

Bantle M, Kolsaker K, Eikevik TM (2011) Modification of the Weibull distribution for modeling atmospheric freeze-drying of food. Dry Technol 29(10):1161–1169

Shi JL, Pan ZL, McHugh TH, Wood D, Hirschberg E, Olson D (2008) Drying and quality characteristics of fresh and sugar-infused blueberries dried with infrared radiation heating. LWT Food Sci Technol 41(10):1962–1972

Alvarez P, Shene C (1996) Experimental study of the heat and mass transfer during drying in a fluidized bed dryer. Dry Technol 14(3–4):701–718

Yang Y, Zhang P, Zhang W, Tian Y, Zheng Y, Wang L (2010) Quantitative appraisal and potential analysis for primary biomass resources for energy utilization in China. Renew Sustain Energy Rev 14(9):3050–3058

Chen DY, Zhang D, Zhu XF (2011) Research on drying mechanism of heat and mass transfer of stalk (I)—TG/DSC experimental analysis. Taiyangneng Xuebao/Acta Energiae Solaris Sinica 32(9):1355–1360

Chen DY, Zhang D, Zhu XF (2011) Research on drying mechanism of heat and mass transfer of stalk (II)—kinetics numerical simulation. Taiyangneng Xuebao/Acta Energiae Solaris Sinica 32(10):1517–1522

He F, Yi W, Bai X (2006) Investigation on caloric requirement of biomass pyrolysis using TG–DSC analyzer. Energy Convers Manage 47(15–16):2461–2469

Artiaga R, Naya S, Garcia A, Barbadillo F, Garcia L (2005) Subtracting the water effect from DSC curves by using simultaneous TGA data. Thermochim Acta 428(1–2):137–139

Cai JM, Liu RH (2007) Research on water evaporation in the process of biomass pyrolysis. Energy Fuels 21(6):3695–3697

Chen DY, Zhu XF (2011) Thermal reaction mechanism of biomass and determination of activation energy I. Drying section. Ranliao Huaxue Xuebao/J Fuel Chem Technol 39(8):580–584

AOAC (1990) Official method of análisis, association of official analytical chemists no. 934.06., 15th edn, Arlington

Cho J, Davis JM, Huber GW (2010) The intrinsic kinetics and heats of reactions for cellulose pyrolysis and char formation. ChemSusChem 3(10):1162–1165

Chen DY, Zhang D, Zhu XF Heat/mass transfer characteristics and nonisothermal drying kinetics at the first stage of biomass pyrolysis. J Therm Anal Calorim. doi:10.1007/s10973-011-1790-4

Yang H, Yan R, Chen H, Zheng C, Lee DH, Liang DT (2006) In-depth investigation of biomass pyrolysis based on three major components: hemicellulose, cellulose and lignin. Energy Fuels 20:388–393

Crank J (1975) The mathematics of diffusion, 2nd edn. Oxford University Press, London

Vega-Gálvez A, Miranda M, Díaz LP, Lopez L, Rodriguez K, Di Scala K (2010) Effective moisture diffusivity determination and mathematical modelling of the drying curves of the olive-waste cake. Bioresour Technol 101(19):7265–7270

Igathinathane C, Chattopadhyay P (1999) Moisture dusion modelling of drying in parboiled paddy components. Part II: bran and Husk. J Food Eng 41(2):89–101

Srinivasakannan C, Balasubramaniam N (2006) Drying of rubber wood sawdust using tray dryer. Part Sci Technol 24(4):427–439

Tirawanichakul S (2008) Paddy dehydration by adsorption: thermo-physical properties and diffusion model of agriculture residues. Biosystems Eng 99(2):249–255

Thakur AK, Gupta AK (2006) Water absorption characteristics of paddy, brown rice and husk during soaking. J Food Eng 75(2):252–257

Acknowledgments

The authors thank National Natural Science Foundation of China (50930006, 50876099), National Basic Research Program of China (2007CB210203), and Knowledge Innovative Program of the Chinese Academy of Sciences (KGCX2-YW-306) for financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, D., Li, M. & Zhu, X. TG-DSC method applied to drying characteristics and heat requirement of cotton stalk during drying. Heat Mass Transfer 48, 2087–2094 (2012). https://doi.org/10.1007/s00231-012-1050-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-012-1050-6